Concrete mark for the foundation of a private house

The basis of a reliable house is a solid foundation, and the strength of the foundation is largely determined by a sufficient margin of concrete strength, as well as its other characteristics: frost resistance, and with a high level of groundwater, water permeability. In order for the house to stand for a long time and without problems, you need a correctly calculated grade of concrete for the foundation. What it is and how to define it will be discussed further.

The main work on the construction site takes place with the participation of cement

The content of the article

Concrete composition for the foundation

Concrete is a material consisting of:

- Astringent. Most often it is cement (Portland cement). There is also non-cement concrete, but it is not used for foundations.

- Placeholders:

- sand;

- crushed stone or gravel.

- Water.

The grade of concrete is determined by the proportions of all these components, as well as by the conditions of its hardening (setting). Optimal conditions for concrete to gain strength are created at a temperature of + 20 ° C. Under these conditions, the process is very active in the first 7 days. During this time, concrete gains about 50% strength. With such parameters, it is already possible to continue construction further. The design strength, which is taken as 100% in design, under such conditions is recruited in 28-30 days. In reality, the process continues further, but at a very low speed. The strength gained after 30 days is not taken into account anywhere - it goes "in reserve".

At what strength can construction be continued depending on the grade of concrete

With a decrease in temperature, the setting time increases significantly (at + 15 ° C it takes about 14 days to reach 50% strength). At a temperature of + 5 ° C, the process practically stops, and under such conditions, winter concrete is already needed - with appropriate additives and / or measures to increase the temperature (wrapped up, heated in a mixer, heated through the formwork or heated directly by attaching heating cables to the formwork from the inside ).

Cement

Various types of Portland cement are used for the production of concrete. The most common are:

- Portland cement - begins to set no earlier than 3/4 hours and no later than 3 hours after mixing. The end of the setting is in 4-10 hours.

- Slag Portland cement - after mixing, depending on the temperatures and parameters of the solution, it begins to set in 1-6 hours, finishes in 10-12 hours.

- Pozzolanic Portland cement - hardening begins in 1-4 hours, ends in 6-12 hours.

- Alumina cement - begins to harden in 1 hour, finishes in 8 (but not later).

The cement grade is needed for the foundation, usually M400 or M500

Any of these types of binder can be used to prepare concrete. Only you will need to take into account the setting time of the solution - you need to lay and vibrate it before hardening.

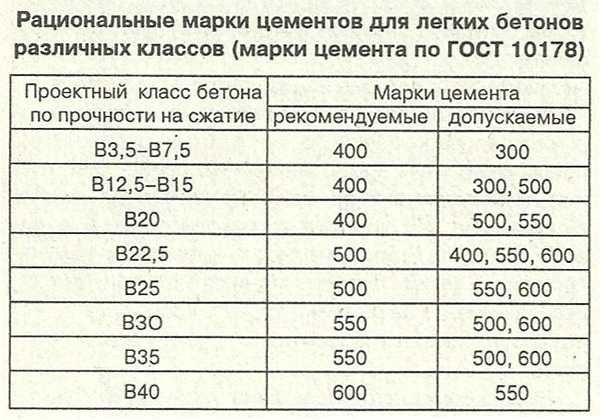

Recommended grades of cement for concrete

Placeholders

The quality of concrete is also influenced by aggregates. It is necessary to adhere not only to the recommended proportions, but also to quality indicators - moisture and graininess.

Sand

Depending on the size of the grains, the following types of sand are distinguished:

- large size of grains of sand 3.5-2.4 mm,

- medium - 2.5-1.9 mm,

- fine 2.0-1.5 mm;

- very small 1.6-1.1 mm);

- thin (less than 1.2 mm).

One of the components of concrete is sand

For backfilling, they mainly use large and medium ones, less often small ones. The sand must be clean - not contain any foreign inclusions - roots, stones, plant residues, pieces of clay. Even the content of dust and silty substances is standardized - they should not be more than 5%.If you decide to "extract" the sand yourself, check the amount of pollutants.

To test 200 cc. centimeters of sand are poured into a half-liter container (can, bottle), filled with water. After a minute or a half, the water is drained, poured again and the sand is shaken. The procedure is repeated until the water is clear. If the sand remains 185-190 cubic meters. cm, it can be used - its dust content does not exceed 5%.

Pay attention to the moisture content of the sand. All proportions are based on dry components. Even dry and loose sand has a moisture content of at least 1%, ordinary - 5%, wet - 10%. This must be taken into account when dosing water.

Crushed stone and gravel

Crushed stone is obtained by crushing rocks. Depending on the size of the fragments, the following fractions are distinguished:

- extra small 3-10 mm;

- small 10-12 mm;

- average 20-40 mm;

- large 40-70 mm.

Crushed stone must be used in several fractions

For the preparation of concrete, several fractions are used - so the distribution of crushed stone by volume is more uniform, and the strength increases. The size of the largest fragments is normalized: it should not be more than 1/3 of the smallest size of the structure. With regard to foundations, the distance between the reinforcement rods is taken into account. SNiP also determines the amount of small crushed stone: it must be at least 1/3 of the total volume.

Gravel has approximately the same fractions and sizes, but when it is used, the water-cement ratio (water / cement or w / c) increases by 0.05 (5% more water must be poured).

Water

For the preparation and pouring of concrete, potable water is used. Including the one that can be drunk after boiling. Sea water can be used with Portland and alumina cement. Any other industrial water is not suitable.

Concrete grade and its choice for strength

Depending on the characteristics of concrete, it is divided into compression classes and the corresponding grades. This correspondence is shown in the table.

| Compressive strength class of concrete | Compressive strength of concrete kg / cm2 | The closest concrete grade by strength |

|---|---|---|

| AT 5 | 65.5 | M 75 |

| B 7.5 | 98.2 | M 100 |

| B 10 | 131.0 | M 150 |

| B 12.5 | 163.7 | M 150 |

| B 15 | 196.5 | M 200 |

| B 20 | 261.9 | M 250 |

| B 22.5 | 294.4 | M 300 |

| B 25 | 327.4 | M 350 |

| B 30 | 392.9 | M 400 |

| B 35 | 458.4 | M 450 |

| B 40 | 523.5 | M 500 |

The compressive strength of concrete is determined by testing. This parameter reflects the load that a given concrete can carry without signs of destruction during its prolonged exposure. According to this characteristic, concrete is selected depending on the load that the house will create (it depends primarily on the weight of the walls and floors, but a lot of factors are also taken into account, including snow loads).

When designing a foundation and determining its dimensions, the load from the building is calculated. This number is one of the parameters for choosing a brand. Find in the middle column of the table a value close to the calculated load and determine the brand.

Example for calculating the load from the house, look here.

Concrete grade for the foundation, depending on the materials of the walls and soils

Projects and calculations are not always carried out. When building summer cottages or baths, developers prefer not to spend money, and develop designs themselves. And although there are many brands of concrete, in private housing construction, mainly three are used for the foundation:

- M 200. This concrete is used when pouring a foundation for light houses - from a log or a bar, panel type, light building blocks (foam blocks, gas silicate, expanded clay concrete).

- М 250. This brand of concrete for pouring the foundation of one-story buildings made of bricks and other materials of the same density, with concrete slabs overlapping.

- M 300 brand of concrete for the foundation of a brick house, but in 2 or 3 floors.

What brand of cement is needed for pouring the foundation depends on the type of building material and soil

Also, adjustments need to be made taking into account the type of soil under the foundation and the level of occurrence of groundwater. If the soils are sandy or rocky, and the water is below the freezing depth, then all recommendations remain valid.If the level of groundwater is high, and the soils are heaving, the grade of concrete is taken one step higher: the conditions are more difficult and a greater margin of safety is required.

Selection taking into account the type of foundation

Concrete grade for strip foundation with a deep bed of water (below 2 meters) and an average degree of reinforcement, it is selected according to the previous recommendations:

- for light buildings - M200;

- for one-story brick - M250;

- for two and three storey brick - M300.

When makingfoundation slab or tape, but with a high level of groundwater, the solution is taken not lower than M350. Moreover, the filler should be only gravel (not crushed stone), and not coated. For filling bored piles M200 or M250 is used.

From all of the above, it follows: what grade of concrete is used for the foundation depends on:

- the material from which the house is built;

- from soils under the foundation;

- from the depth of groundwater;

- on the type of foundation.

The grade of concrete for the strip foundation of a private house depends on the soil and the type of building material

All this seems complicated, yes, in fact it is, but after all the calculations, in 90% of cases, when building small houses, summer cottages, baths, garages, concrete of the M200 or M250 brand is used. And its strength is usually enough with surplus. The main thing is to keep the proportions correctly when mixing, mix everything well - only a homogeneous solution can give the required strength. It is also important to treat the mortar well with concrete vibrators when laying. This treatment alone increases the grade of concrete by one step (it becomes more durable, increases frost resistance, less water is absorbed).

Read how to make a concrete mixer with your own hands here.

Other characteristics

In addition to the main characteristic - strength, concrete has a number of indicators that can affect the choice of a brand under special conditions of construction or operation.

Frost resistance, water resistance and workability of concrete grades

- Frost resistance - denoted by the letter F. Shows how many freezing-defrosting cycles a given solution withstands without loss of strength. It is clear that the higher this indicator, the better (see the table). The concrete grade for frost resistance for the foundation is taken into account during the construction of unheated premises (baths, dachas of periodic visits). When building houses of permanent residence, this indicator can be disregarded, especially if the foundation is insulated and insulated around the perimeter of the house blind area.

- Waterproof. It is designated by the letter W. This indicator determines how much moisture the concrete will absorb. After the letter W there are numbers from 2 to 10 (in fact, there are W20 brands, but they are not used in private construction). W2 and W4 - high to normal absorbency. Concrete grades with such water resistance can only be used on well-drained soils (sands and sandy loams) with deep groundwater. At W6, moisture absorption is already reduced, and a solution with such characteristics can be used for foundations on soils that do not drain water well. With water resistance, the W8 absorbs only 4.2% of the total mass of water, and the W10 even less.

One of the parameters is fluidity

- Conceivability. It is designated by the letter P, after which there are numbers from 1 to 5.

- P1 - cone sediment 1-4 cm, semi-rigid or low-plastic solution (almost does not slide off the inclined shovel);

- P2 - cone draft 5-9 cm, medium plastic - slides off an inclined shovel;

- P3 - sediment 10-15 cm, half-lump - when it flows down from an evenly standing shovel;

- P4 - sediment 16-20 cm - cast - practically fluid.

- P5 - the cone settles by more than 21 cm, the solution flows.

In terms of workability, it affects how comfortable you will be with the grout. For foundations, concrete with the P2 characteristic is most often used (with frequent reinforcement, P3 is used). It is permissible to use P1 with obligatory processing with a concrete vibrator - it settles the solution well, making it more homogeneous.

Considering all these characteristics, we can recommend the following grades of concrete for the foundation for one-story houses.

| Type of one-storey house | Weakly loose soil | Fluffy soil |

|---|---|---|

| Panel, frame house | M-200 (P3 F100 W4) | M-250 (P3 F150 W4) |

| House from a bar and a log | M-250 (P3 F150 W4) | M-300 (P3 F150 W6) |

| House made of aerated concrete, foam concrete, expanded clay concrete | M-300 (P3 F150 W6) | M-350 (P3 F200 W8) |

| Brick, monolithic house | M-350 (P3 F200 W8) | M-400 (P3 F200 W8) |

Remember that when building a two-story house, the concrete grade increases by one step from those shown in the table.

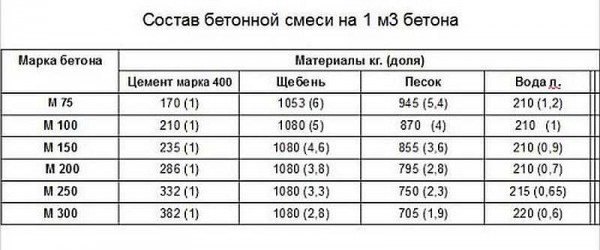

Component proportions for concrete

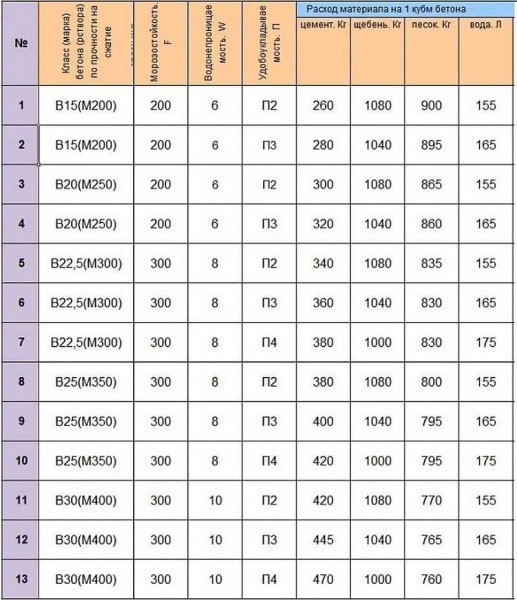

In formulations, concrete formulations are given by weight or volume. Moreover, cement is always taken as 1, and all other components are taken in relation to it. The proportions for commonly used brands are shown in the table.

As you can see, the same concrete can be obtained using different brands of cement. Whatever it is, go to sleep like this, only adhering to the recommended mass (or volumetric) proportions. Basically, when pouring foundations, Portland cement M400 and M500 are used. When mixing, remember that if gravel is used instead of crushed stone, 0.05 more water is added.

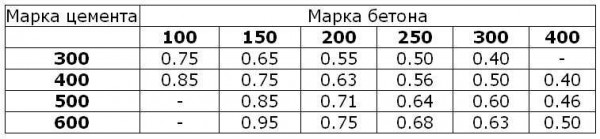

How to decipher the instructions in the table? For example, take the Concrete Grade M250, it will be composed of M400 Portland cement. We will focus on mass. Then select the corresponding row in the third column: 1 / 2.1 / 3.9. This means that for one kilogram of M400 cement, we take 2.1 kg of crushed stone and 3.9 kg of sand. The amount of water can be taken from the table below - it is 0.65 kg for filling from crushed stone.

Water-cement ratio for different grades of concrete

If we compose the same concrete, focusing on the volume, for example, a 10-liter bucket, then we take the proportions from the fourth column: 10/19/34. This means that for 1 bucket of cement, we put 1.9 buckets of sand, 3.4 buckets of rubble. The water / cement ratio remains the same: 0.65 buckets.

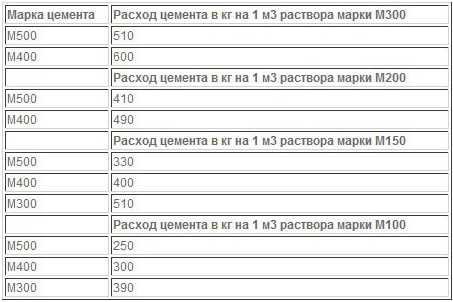

Sometimes you need to calculate how many components are required for one cube of concrete. These data are summarized in the following table.

Another table summarizes data on the consumption of cement M400 and M500 per cubic meter of the most popular brands of concrete in the construction of the foundation.

Cement consumption per one cubic meter of concrete of different grades

A correctly selected brand of concrete for the foundation is the key to its strength. But high quality compositions are very expensive. If, according to all the above recommendations, you need to use M300 and higher, it is better to order foundation calculation, which will confirm or refute your assumptions. The cost of this service is about $ 100-150, and it can save thousands if you need a lower brand.

The main thing is to pay more attention to the transportation of concrete, even better

carried out by concrete mixer trucks. It helps you stay mobile

mixtures.

You need to buy good concrete for the foundation, after all, the house will not stand for 1 year

A very good and informative site. Everything is described and painted very competently. Thank you very much . I would like to clarify. I am going to build the foundation chose concrete B 25 (M350) P4 F 200 W 8 for the pile grillage foundation. Do you think this concrete grade is suitable or not? Tell me please, I will be grateful.

In fact, for a reasonable answer, you need data on the number of storeys of a building, its mass, type of soil, size of pillars, their shape and type (with or without a heel), placement scheme and a whole bunch of other things ... but you chose high grade concrete - M350, its durability is sufficient with a margin for most private buildings. So it will probably do.