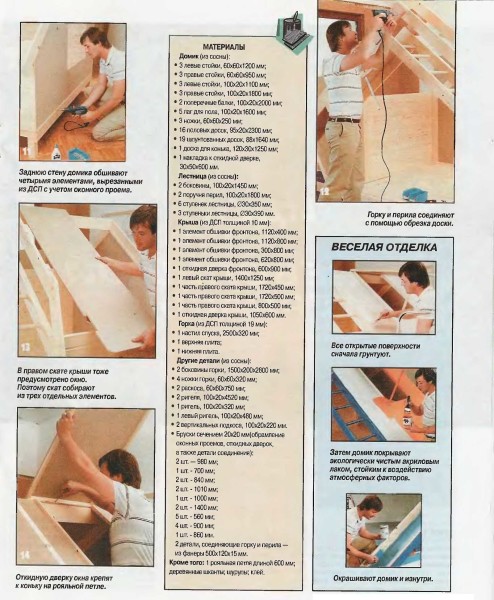

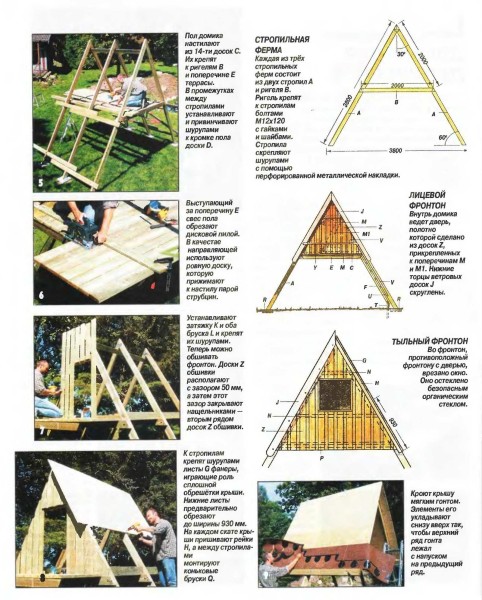

Play house for children: step by step photos, diagrams, drawings

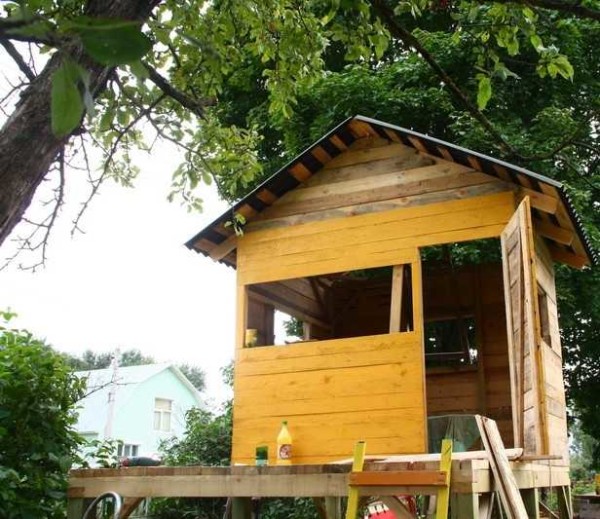

From the point of view of psychologists, every person and especially children need their own territory. It is not for nothing that they have a craving for the construction of huts, halabuds, bases and other buildings from any suitable and not very materials. If you have your own yard or a child spends a lot of time in the country, build a children's house for him. The easiest way is using wireframe technology. Examples of the construction of wooden playhouses for summer cottages in photo reports.

The content of the article

Playhouse for summer cottages with a sandbox below

We bring the brought beam 100 * 100 mm to smoothness. You can use a plane, you can use a drill with a fixed skin. First with a large grain, then with a small one. After we treat it with a protective compound against decay, paint it. While the pillars are drying, we drill holes (our diameter is 23 cm, depth is 60 cm). We fall asleep in them to the bottom near the crushed stone shovel. We put the pillars, set them vertically, fill them with crushed stone, compact them, and concrete them.

We cut the exposed pillars all into one level. We fix the same beam 100 * 100 mm from above. It is also carefully processed so that there are no splinters. We connect in half a tree: at the ends we cut out recesses in half the thickness of the timber. For a beam of 100 * 100 mm, cutouts of 50 mm in depth and in an area of 100-100 mm: so that the same sawed edge of another beam lies flat.

We fix it securely: on top of 2 long nails (200 mm), on the sides of the corners with screws.

We attach an additional beam on the long side. Under it, in the middle - above the rack - we cut out a recess also half the thickness of the timber - 50 mm. It is no longer necessary for the wood to burst. We cut the laid timber at the ends in the same way as those that go along the perimeter: in half a tree. It fits into the prepared gash.

The children's house must have a solid margin of safety. Therefore, we are reinsured in every connection. To give the structure stability under lateral loads, we will put jibs. We cut them from a bar of 50 * 50 mm, cut the ends at 45 °.

Putting it by surprise, clenching it well.

After installing the jibs, we lay the board. This will be the floor of the house.

We cut the flooring from the boards. It is more convenient to work with an electric jigsaw, but you can also use a hacksaw.

On the finished flooring, we assemble the frame of the play house. We use a beam of 50 * 50 mm. We set the bars strictly vertically, fasten them first with nails - two on both sides, then reinforce them with corners on self-tapping screws (also on both sides).

We increase the rigidity of the structure by installing jibs. Then we nail the harness of the second floor. We just nail these bars between the posts. They must be sawed off with great accuracy so that the building does not warp. We strengthen the joints with corners, then we put jibs.

We do not nail the jibs in the place where the entrance will be.

Next, we put intermediate racks to form windows. The fastening method is the same: two nails at the top / bottom, then two corners.

Sheathed with a board left over from the equipment packaging. You can use from pallets, buy an inch board (12-13 mm thick), sheathe with clapboard or imitation of a bar, log, siding.

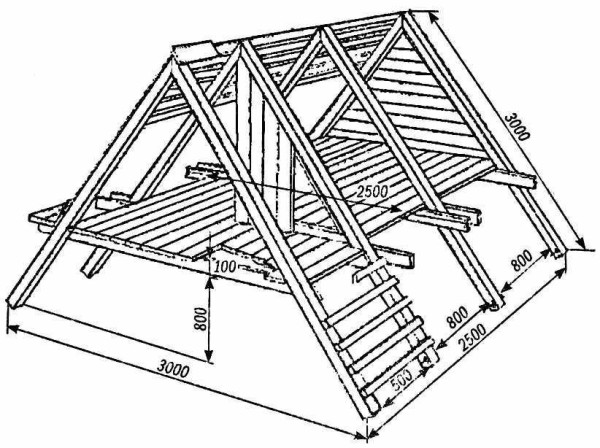

When the sheathing is almost finished, we begin to assemble the rafter system.It is easier, of course, to make a pitched roof - to make one wall higher and no problem. But the gable looks better, although it is more difficult to perform.

For the rafter system, we put two boards per edge, connect at the top, sawing off the corners. The rise depends on the desire and the amount of snow. If there is a lot of snow, raise the skate higher. If not, it can be about a meter or less. We knock down with nails, then we reinforce the connection with overhead plates.

When building houses, either a metal plate or a piece of board is placed here. Decided to use a board.

Next, you need to form a wash down so that the resulting triangle rests on the upper bar. We put it, mark the place and roughly cut it out. Then we adjust so that the rafters "sit down" tightly.

According to the finished sample, we mark out other rafters. Cut out, knock down under two rafter legs at an angle (all should be the same as a carbon copy). Having installed it on the top of the house, we check the verticality. Then we nail with two nails on both sides and set the corners.

Now sheathing boards are laid on the rafters. The roofing material will be ondulin. We put the board 11 * 100 mm with a step of 30 cm.

Based on the thickness of the board (11 mm), we take self-tapping screws 25 mm long for fixing the ondulin (so that they fit well into the board. We put rubber gaskets under the caps so that it does not flow.

Next - finishing work and security - railings.

Handrail made from processed, sanded board. They are screwed onto powerful self-tapping screws 90 mm. Two for the bottom beam - one for the planking.

At the top, the railing is connected with a 30 * 30 mm bar. Then a board will be nailed to it - a handrail.

It was decided to put a sandbox below. It is not difficult to assemble: eight boards on the walls, connected at the corners with the help of bars, A board-side is nailed on top. Then the sandbox is painted.Read about how to make sandboxes here.

Even a “non-builder” can build such a children's house with his own hands. There are no particularly complicated works, you can get by with an elementary tool.

Several options from the same series are shown in the photo below. Two are houses with a slide, and one is a one-story version, more suitable for girls.

The independent production of a playground is described here.

How to make a children's house from OSB and plywood (frame technology)

It was decided to make a house using frame technology - a base from a board, sheathing from OSB. The dimensions in the plan are 3 * 2 m, the height of the walls is 1.5 m, in the ridge 2.2 m. Boards of 50 * 100 mm were purchased for the frame, an inch board (100 * 12 mm) for the subfloor, OSB 9 mm for the floor and outer sheathing , for internal - sanded plywood FSF 6 mm, foam for insulation 100 mm thick.

Preparatory work - the assembly of boards for the orphanage - was carried out in the garage: it is still cold. Later, as it gets warmer, the house will move to the country house, to the place of permanent registration.

The first stage is the manufacture of the floor frame. We knock down a rectangle with sides 3 * 2 m, nail down transverse boards (floor logs) with a step of 50 cm.

The floor will be insulated with foam. Children love to sit on the floor, so we insulate well - with 100 mm foam. We fill thin strips under it from the lower side - so that it does not fall through. We insert the foam. The slots can be filled with polyurethane foam.

It's good that the building is small. We put on the side and hem from below with an inch board. This will be the subfloor. After turning it over, we sew up the OSB.

Later, when the house was taken to the dacha, an error in the installation of OSB was revealed.He was nailed close. In the humid air, the material swelled and the sheets were bent in some places. Therefore, when installing sheet material, leave a gap of 8-10 mm.

Next, we collect the frame of the walls. We put the racks in increments of 1 meter, under the windows and doors - doubled. Since the top will be stuffed with OSB on one side, and plywood on the other, the structure will be rigid. We do not put jibs. They are needed if the orphanage will be upholstered with clapboard or other rack material.

The work was moved to the dacha. Three old logs were used as a foundation. They are hewn, the tops are aligned. The logs are set on a level, a board is nailed onto them, on which the platform will be installed. The width of the house is 2 meters, and the logs are 3 meters long. We will arrange the rest as a terrace or porch.

We installed the platform. It is attached to the logs with large pins that connect the log and the platform. We began to expose the frame of the walls. They must be placed exactly vertically. To fix, they used temporary cuts - they nailed them with boards on the side.

Along the way, having exposed and checking whether the wall is level, we nail it to the platform with long nails. The length of the nail is such that it at least reaches the middle of the frame board.

Next, the assembly of the rafter system begins. First of all, we put a ridge - a board in the middle, which will form the roof slope.

Then the fittings begin: you need to properly cut the corners under the rafter legs so that they lie flat on the boards. First, we cut it out approximately, gradually ensuring that there are no gaps.

When the shape of the cuts is clear, we transfer it to other boards using a sharpened pencil. We cut everything evenly (with a jigsaw, if available, or with a hand saw). Then we nail all the boards to the frame. We stuff transverse boards between the rafters - the ondulin will rest on them. It turns out such a house.

After the construction of the rafter system, only the cladding remains - inside and out. Outside we stuff OSB. We make it so that the joints fall on the racks. We nail it down, you can use wood screws. Whom it is more convenient.

Then it's up to the interior decoration and insulation. First, a windproof membrane is stuffed (so that it is not cold), then basalt wool is attached (10 cm thick, so that it becomes just at the depth of the board.

Everything is nailed from above with plywood. And that's all. It's done - paint it and you can put it into operation)))

Using the same technology, you can build a tree house. It will be necessary to secure the site, and everything else is very similar.

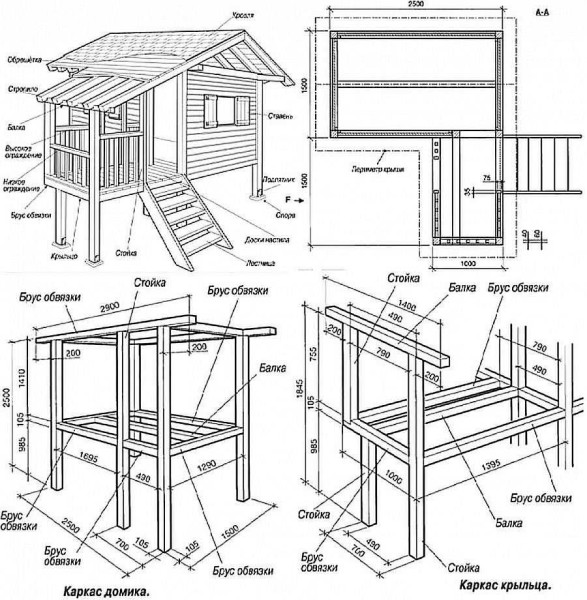

Drawings and diagrams

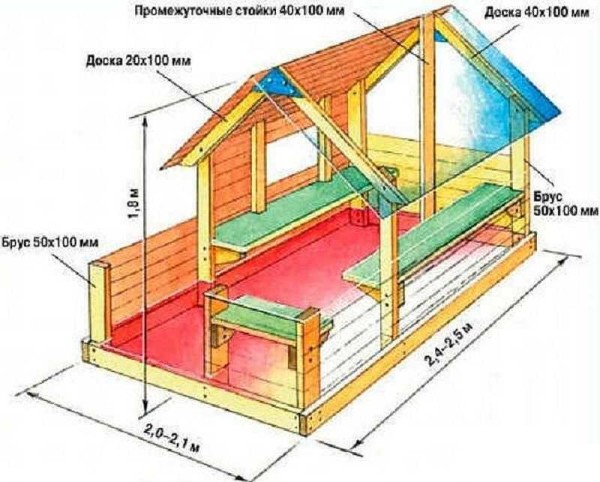

Each homemade orphanage differs in size. Based on how many "inhabitants" are planned in it. If the child plays alone, then 1.5 * 1.5 m is more than enough. If there are two children, larger sizes are already needed. At least 2 * 2 m. In height, too, decide for yourself. But it is better not to do less than 1.5 m.

House made of boards and plywood with a slide roof

Hello! Nice photo report, thanks! Could you tell me the dimensions of the house itself?

This one was 1.8 * 2.5 / 2 m. The height of the house was taken taking into account that an adult could be inside.