Fiber siding or fiber cement panels: what is it and how to install it

Choosing a material for decorating the facade of a house is far from easy. It must be beautiful, durable, durable, and require minimal maintenance. And I really want it to be inexpensive. It is unrealistic to meet all the requirements at the same time. Well, no, yet, such material. If you omit the "cheap", you can consider fiber cement siding. In addition to all the advantages, it is also non-combustible and compatible with all types of walls.

The content of the article

What is fiber cement siding or panels

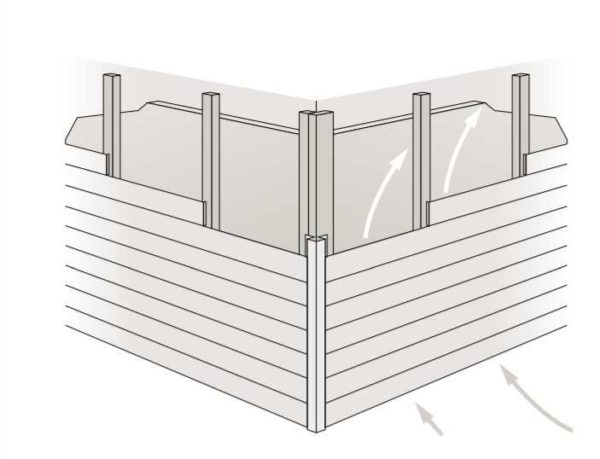

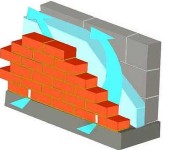

Fiber cement siding or slabs (fiber siding) is a cement-based composite material that is used for exterior facade decoration. It is mounted on the principle of a ventilated facade - on a crate. Some systems allow installation on a wooden frame, others (Japanese) recommend only their own - made of metal.

There are two forms of release:

- In the form of long boards of varying thickness and width. This type of material usually imitates wood. Actually, this particular type is called fiber siding and the fastening system is similar to conventional siding.

- In the form of slabs of different formats. This category can include smooth panels or imitating brickwork, stone, etc. They are also not mounted with a crate, but they have their own characteristics.

The composition of fiber cement siding differs from manufacturer to manufacturer, but it is always based on cement and reinforcing fiber. Some add cellulose fibers (almost all), others include fine sand fractions, there are additions of mica or other minerals. The type / appearance of the outer surface changes depending on the additives.

Fiber plates and fiber siding can be painted in bulk or on the surface (acrylic paint). There are options with an external ceramic coating (very expensive), there are options without staining - for your own painting. Ceramic coated - very beautiful and durable, but also very expensive. Clinker tiles will cost about the same. It is a little easier to work with material dyed in the mass during installation - no need to tint the ends and cuts. It is also better in the sense that there will be no color difference on the chips. But, over time, the paint on the surface will fade, you will have to update the color. The same as with painted on the surface. But the cost of dyed fiber cement materials is higher.

The cheapest option is fiber cement siding or unpainted slabs. In this case, you are your own designer.

If we talk about similar materials, then when sawing, fiber cement siding and slabs are very reminiscent of asbestos-cement products. The only difference is that instead of asbestos, fiber is used. Well, and they look different - more solid.

Advantages

We will talk specifically about fiber cement siding, because it is more common than slabs (due to the price, mainly) and there are more reviews and operating experience. In general, the material is recognized as worthy, not capricious in operation. But this is on one condition: with proper installation. Each of the companies has installation instructions and it has more than a hundred pages. It describes specific nodes and processes. If you do everything according to the rules and recommendations (or deviate quite a bit), then a good result is guaranteed.

It is important to follow the technology. Painting the cuts and mounting locations is one of the key points

In general, the advantages of fiber cement siding are:

- Dimensional stability. There is thermal expansion, but it is not great.

- Fiber cement boards and boards are not hollow, without voids. Corners and joints can be made "end-to-end", without the use of additional elements, as in vinyl siding trim.

- Does not burn.

- The material is dense, hard. With a properly assembled frame, it almost "does not play", does not squeeze, you can lean against it, it is difficult to break.

- High frost resistance - 50 cycles for "Rospan", 150 "Enterit", 300 Japanese "Nichikha".

- Subject to the installation rules (painting the ends, cuts, fasteners with a suitable paint), low water absorption - no more than 8 (Japanese plates) - 18% of the mass when immersed in water for 48 hours.

- Undemanding care. An attractive appearance remains for a long time, no paint renewal is required. For example, "Kedral" guarantees color fastness for 10 years.

- You can mount it at any time of the year. Only a touch-up of seams and chips can be done at positive temperatures, which still imposes certain restrictions on the installation time.

- You can cut with a hacksaw - a blade with hardened teeth, a circular saw or angle grinder (grinder), a jigsaw. When using a grinder or circular saw, the recommended discs are Leitz or Bosch fiber cement. For a jigsaw, special fiber cement files are also needed.

It's all about virtues. In short, we can say that with normal quality, there are no complaints about fiber cement siding. It can be operated for years without requiring absolutely any attention.

disadvantages

Like any material, fiber cement siding or slabs have disadvantages. If we talk about operational aspects, there are almost no drawbacks. Correctly mounted, it does not change for a long time. Even the pieces left on the street have not changed in a year, and their ends are not repaired. But all this concerns the quality material. And yet, there are also disadvantages:

- High price. It consists not only of the cost of the panels themselves or siding. The costs also go to the structure to which all this will be attached, plus expensive fasteners that are not subject to corrosion.

- Complex installation. In the sense that the nodes must be done as the manufacturer recommends. It is also necessary to use the recommended composition (paint or sealant) to process joints, joints, cuts, and places where fasteners are installed. All this time, and the paint / sealant costs a lot.

- Quite a specific look when using fiber cement siding. But one can argue about this, since there are different textures, and you can combine them in different ways, getting a different style and look - from modern to classic.

- A lot of weight that must be taken into account at the planning stage of the foundation. And not all walls can be "hung" with a large mass.

In general, fiber cement siding and slabs are not the cheapest, but good material. It has been on our market for more than a decade. If it were bad, there would be a sea of negative reviews and complaints. They are not. There is a generally positive operating experience with some nuances, which are usually caused by errors in installation.

Installation: what and what

Fiber cement siding is installed according to the principles of a ventilated facade, that is, on a crate with the possible use of insulation. As already mentioned, each company has its own installation manual. It is freely available. We recommend that you carefully read the manual before buying a fiber cement siding from this or that company. If you plan to mount it yourself, it's worth having an idea of what and how to do. Even if you plan on hiring an installation crew, it doesn't hurt to know how everything should be done. After all, each manufacturer insists on the fact that long-term operation is possible only with correct installation.

Mounted on a crate. The minimum gap is 2 mm, the step is no more than 600 mm, when using a metal subsystem, the recommended thickness for our weather is 2 mm

The lathing for fiber cement siding can be wooden or metal.

- It is recommended to install the metal frame on concrete, brick and aerated concrete buildings. It can be stainless steel, galvanized steel or aluminum alloy.

- The wooden lathing is recommended for timber or frame houses. They make it mainly from a bar of 50 * 50 mm, but there may be options with a width - maybe 50 * 40 mm, and 50 * 30 mm. A prerequisite is to use dry timber with preliminary protective impregnation on the crate.

"Native" fastening systems of manufacturers of fiber cement boards and road siding. Therefore, even on brick or concrete walls, wood is used for the frame. We have it cheaper. Be sure to put a metal starting profile, everything else is collected from a bar. As practice has shown, if you use dry wood with high-quality impregnation and do not neglect the recommendations for fasteners (the mounting hole in the plate is slightly larger than the diameter of the fasteners), no problems arise.

Fasteners, by the way, must also be taken that are not prone to corrosion. Stainless self-tapping screws are expensive, of course, they can be replaced with galvanized and galvanized ones. But not with an aluminum subsystem. Attach to it only with stainless steel fasteners.

Types and methods of docking

Most fiber cement siding is installed in a herringbone pattern, with one board covering the other. So they usually sheathe houses with clapboard. The main advantage of this method is the minimal possibility of water flowing between the boards. The moisture simply flows down, as the boards overlap each other by 25-30 mm (depending on the size of the board). But at the same time, there is an increased consumption, since with a width of 19 cm, only 15-16 cm remains "working".

The second type of joining of fiber cement siding boards is butt joint. It was implemented by the Belgian company Cedral in a click series. The board of this series has a quarter-cut, is inserted into one another, fixed with self-tapping screws on clamps (small mounting plates for hidden fastening). In this case, the surface of the board does not need to be drilled, since the clamp tongue clings to the ledge of the board and thus holds it.

The corners and joints of fiber cement siding can be decorated with additional elements - corners, you can join them by sawing the boards at an angle of 45 ° and smearing the cut with paint. A can of paint is issued / purchased for the siding batch, which is used to paint your material. Japanese facade fiber cement panels are coated not with paint, but with the recommended sealant. By the way, under the additional elements, the cuts should also be painted over. The holes for the fastening are also coated with the appropriate means.

If you like the design with finishing the corners, and you don’t like the price of these corners (much more expensive), there is an option - cut the same board lengthwise (of the same or a different color), paint the cut and connect them at the corner with self-tapping screws. It is clear that upon closer examination, this option will lose in aesthetics, but if the budget is limited, it is a good way to save money.

Characteristics and prices of facade fibrosiding from different manufacturers

The Japanese Nichiha (Nichiha) appeared on the market before all other manufacturers, followed by the Belgian Cedral (Cedral). Both brands do not differ in affordable prices, but they have stable quality. The Japanese stand out for their texture and ceramic self-cleaning coating, which are guaranteed for 50 years. Currently they have 6 series, each series - from 20 to 120 different textures and patterns. There are different stones, bricks, plaster. There are a lot of options, so there is plenty to choose from. Today they have the widest range of finishing fiber panels. The disadvantage is the high price, as well as the fact that the seams between the panels are visible. The last flaw is fixed in the new FUGE series.

Fibrosiding Cedral (Cedral) is produced by the large company Eternit, which is headquartered in Belgium. One of the factories was launched in Russia.He produces products of decent quality. For use in low-rise construction, only two rulers are available - with a regular edge (overlapping installation is possible) and with a lock for butt installation. The surface imitates wood (qualitatively, I must say), there are no other delights.

| Name | Cedral (Cedral) | Cedral Klick | Latonit (Latonit) Russia | Rospan (Russia) | Nichiha Nichiha (Japan) |

|---|---|---|---|---|---|

| Length / width / thickness of one board | 3600/190/10 mm | 3600/186/12 | 1800; 2200; 3000; 3600/200/8 mm | 1593 * 455 (306) * 14 mm | 3030/455/16 mm |

| Weight of one board | 10.9 kg | 12.2 kg | 4.8; 5.8; 7.9; 9.5 kg | 9.6 and 14 kg | |

| Usable area of one board for overlapping installation | 0.576 m2 | - | overlap can be from 20 mm to 40 mm, area 0.36-0.72 m2 | ||

| Useful area of one board when mounting butt | 0.684 m2 | 0.6228 m2 | 0.306-0.612 m2 | 0.49 m2 or 0.72 m2 | |

| Weight per square meter | 15 kg / m2 | 18 kg / m2 | 16.9 kg / m2 | 19 kg / m2 | |

| Density | 1300 kg / m3 | 1300 kg / m3 | 1650 kg / m3 | 1400 kg / m3 | |

| Flexural strength transverse / longitudinal | 23/11 N / mm2 | 23/11 N / mm2 | 215 kgf / cm2 | ||

| Modulus of elasticity, transverse / longitudinal | 7500/5500 N / mm2 | 7500/5500 N / mm2 | 45-65 MPa. | 12.2 MPa | |

| Expansion from moisture | 0.3 mm / m | 0.3 mm / m | Water absorption 16% | 1,82% | |

| Expansion with temperature | 0.212 mm / m | 0.212 mm / m | 2% | ||

| Frost resistance - cycles / residual strength | 150 cycles / 90% | 150 cycles / 90% | 150 cycles / 90% | 150 cycles / 90% | 150 cycles / 90% |

| Price | 1124 rub / m2 | 1200 rub / m2 | 730 rub / m2 | about 1000 rubles / m2 | from 1500 rub / m2 |

Rospan and Latonit are usually distinguished from Russian manufacturers. In terms of assortment, they are more modest, they give a 10-year warranty on their coverage. Latonite differs in that it produces boards of different lengths - from 1800 mm to 3600 mm. Fiber cement siding Latonit has a smaller thickness - 8 mm, which allows it to be made cheaper, but its strength will also be lower. The company can produce panels without a finishing UV protective layer - for use inside buildings. There are also unpainted products - for self-painting.

All in all, you've probably figured out that fiber cement siding and panels are great choices, but that's not too budgetary.

Interesting ideas and some knots

I have a house built with siding sheathed. Several years at home already.