Plastic cellar - reliability and durability

What to do if there is a high level of groundwater on the site, but it is necessary to make a storage for products. The exit is either a steel welded caisson or a plastic one. In terms of reliability, plastic is more durable, as steel rusts over time and begins to flow.

Caisson - it is a sealed structure, often of a cylindrical shape.

The content of the article

Advantages and disadvantages of plastic cellars

When building a cellar from building materials, you have to think about waterproofing - so that groundwater does not get inside. A plastic container is guaranteed to protect against this phenomenon and this is its main advantage. Sellers announce a large list of pluses, but if you remove the husk, there is not much left except tightness:

- Plastic is durable, chemically neutral, feels good in soils of any acidity.

- Plastic is not damaged by insects, rodents. This material is simply not interesting to them.

- The walls are easy to clean from any type of dirt.

- If necessary, it is easier to carry out disinfection - spores and bacteria do not "eat" into the walls. If you take everything out of the cellar, the plastic surfaces can simply be treated with a chlorine solution.

- Even if the water (condensation, for example) will stand for a long time, nothing will happen to the walls / floor.

All this is good, but there are significant drawbacks that limit the use of plastic cellars. Since the container is airtight, a kind of "ship" is obtained. With a high level of groundwater in the spring flood, it can be pushed / squeezed out. And this is the main problem that we have to fight. It is solved during installation - a whole list of measures is needed to avoid the ascent of the cellar.

The second solid minus is the high price. The cost of a plastic caisson for a cellar is 70-160 thousand rubles without installation. Installation measures can "pull" about the same. If you do everything yourself it will, of course, be cheaper, but it will still be a lot. So it's worth thinking carefully whether you need a plastic cellar or is it better to build a brick / concrete one.

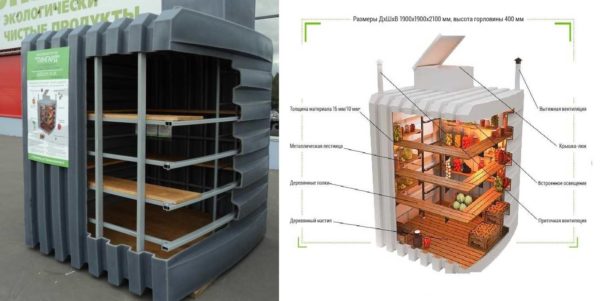

Types and device

A plastic cellar is made using two technologies: it is welded from plastic sheet or poured in layers. Both methods give almost the same result. When welding, the molten plastic does not leave seams, the surface becomes monolithic. And this is really so - there are no complaints about the appearance of a leak in the seams. So there are no special advantages in injection molding technology. And there, and there, the quality depends on the observance of technology and staff qualifications.

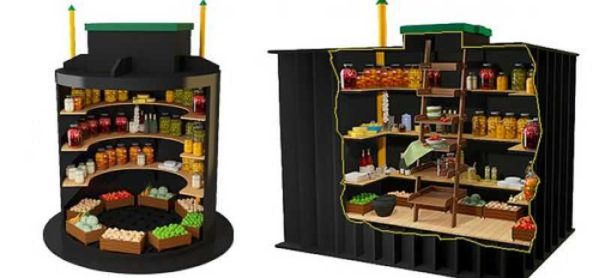

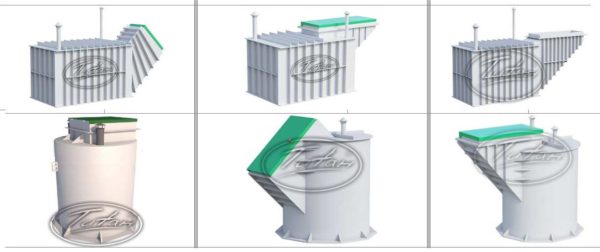

The shape of the plastic caisson for the cellar is cubic or cylindrical. The cube is more familiar in the sense that ordinary cellars are made square or rectangular. The cylinder - with its rounded structure - is perceived as less comfortable, although this is far from the case. Cylindrical - due to their shape - are less likely to be pushed out.

If you have clay soils and / or a high level of groundwater in your area, it is better to pay attention to a cylindrical plastic cellar. It is more likely to remain in place even after many years, and this despite the fact that the installation is less complex and cheaper.

Since the container is sealed, ventilation is necessary to maintain normal humidity. For this, in addition to the entrance, two holes are made in the roof for ventilation pipes. Plastic pipes are installed. One with a length almost to the bottom of the tank is the supply one. Through it, fresh air enters the caisson. The second - exhaust - ends almost under the ceiling.From there, air is taken in and taken out into the street.

Also, in order to be able to conduct light into the cellar, a small diameter hole is made in the roof - 15-20 mm. A cable is put through it, after which it is sealed.

Before buying, check in what form the product will be delivered to you. Many manufacturers immediately put shelves, stairs and their cost is included in the total price. In some models, the shelves are made of plastic and are at the same time stiffeners. Others are equipped with wooden shelves, although the plastic supports are already installed. Some manufacturers offer to sheathe the walls, and if you want, the floor and ceiling with wooden clapboard. It is difficult to say how reasonable this design is, but there is a proposal.

What to look for when buying: selection options

The plastic cellar, buried in the ground, will be pressed by soil and water. If the soils are prone to heaving, at certain periods the pressure is very high, therefore very strict requirements are imposed on the structure.

- The wall thickness is selected depending on the "weight" of the soil.

- If you install a plastic cellar for a summer cottage or at home, you will be in areas with low water levels - they are at least 0.5 meters below the bottom of the caisson - you can look for a not too expensive option with a wall thickness of about 12-15 mm.

- If, at a low water level, the soils also drain water well (sand, sandy loam, peat bogs), containers with a wall thickness of 10 mm are suitable.

- With a high level of groundwater and on heaving soils, thick-walled options with a plastic thickness of about 20 mm are required.

- Walls, floor, ceiling must have stiffeners. They are cast (ribbed surface) or welded. Smooth walls create less resistance and are easier to push out of the ground.

- For better resistance to compression, the stiffeners can be reinforced with steel rods (for example, POLEX plastic cellars). The second method of strengthening is an internal steel frame, which is also a support for the shelves. This is how Tingard solves the problem. Reinforcement of walls and floors is especially important for heaving soils.

- The plastic must be food grade. Polyethylene or polystyrene - not important, but food grade. This is a mandatory requirement if you intend to store not only banks.

- It is very good if there is an extension on the outside at the bottom of the container - a skirt. This design resists buoyant forces better.

This is the minimum set of requirements that will ensure the stability of the shape - the walls and bottom will not bend under soil pressure or heaving forces. In addition, with proper installation, it will be possible to hope that the caisson will not float during a flood.

Installation rules

Specific recommendations for installation will be given by the manufacturer and they should be a priority when it comes to, for example, a layer of soil that should be on top of the roof. It is also worth listening to the recommendations for backfilling the pit. We will give a general installation scenario, and in relation to the most difficult case: a high level of groundwater paired with heaving soil.

To prevent the ejection of the plastic cellar under the influence of groundwater, a reinforced concrete slab is laid or cast at the bottom of the pit. The thickness of the slab is 20 cm, the dimensions should be at least 15-20 cm larger than the dimensions of the container.When self-pouring, a double frame of reinforcement (12 mm or less) is knitted as when pouring slab foundation... If you make the slab yourself, you need to wait at least 2 weeks for the concrete to gain sufficient strength. Then you can continue to work.

The procedure for installing a plastic cellar is as follows:

- Dig a pit, the depth of which is at least 40 cm more than the height of the container to the edge of the neck.Align the bottom, tamp it (it is better with a tamping machine, if not - you can simply mechanically - with a deck with attached handles and a plate on the bottom.

- Lay a layer of geotextile with a density of 200 g / m2. The canvas should be 50 cm larger than the pit size on each side.

- Lay 20 cm of gravel on the geotextile, level it.

- Lay or cast the slab. To make the plate more stable, we use longer reinforcement when knitting the frame. We do it with outlets - it can reach the walls of the pit. When casting the slab, do not forget to embed studs or other fasteners to fix the caisson. These studs / hooks must be stainless steel.

- A plastic cellar is placed on the finished slab for a summer residence or at home, fixed to the slab using stainless ropes or plastic slings.

- Thermal insulation of walls. To maintain a positive temperature inside the cellar in cold weather, the walls must be insulated. It is better to lay extruded polystyrene foam in the ground. Thickness - 50 mm. How deep? 10-20 cm below the freezing depth.

- Backfilling the pit. Before backfilling, turn the geotextile, lay the gate on the slab. You can fix it with something so that it does not wrap back. But further there may be options:

- Some manufacturers demand to fill with concrete, and even reinforce the walls in two rows. It will, of course, be reliable and nothing will come out, the walls will not bend. But what is the plastic caisson for then? For waterproofing only? So, with mastic for pools, you can smear concrete walls and achieve the same result, and the cost of waterproofing will be 10-20 times less, even if you take very expensive compounds and apply in several layers.

- It may be necessary to backfill with a sand concrete mixture. Construction sand and concrete are mixed in certain proportions (specified by the manufacturer). The space between the cellar wall and the pit is filled with this mixture. When backfilling, the mixture compresses well. When it rains, this mixture will gradually turn into concrete. So this is one of the subtypes of concreting.

- Backfilling with sand or gravel. In this version, the backfill will act as a damper for frost heaving forces. But looser aggregate will help water collecting here. Since plastic does not react with water and is not afraid of it, this option is possible.

- Backfilling with "native" soil. These recommendations are given by manufacturers who are confident in their product. Nothing prevents you from filling it with sand or gravel.

- Insulation of the top. It is advisable to lay the insulation not only over the container, but also grabbing 1-1.5 meters to the sides. This is a guarantee that frost will not settle on the roof in winter and moisture will not condense in summer. Insulation - 50 mm extruded polystyrene foam. Lay in two layers with a gap in the seams.

- Filling the slab or backfilling with soil. The stove is poured if the GWL is very high. The additional load is only a plus. You can fill up with soil if the situation is not so dire.

As you can see, the installation is quite complicated, but this is for a "difficult" case - high groundwater and clay or loam. Although, such conditions are a reality for most regions of our country.

Stairs and entrance

Usually, a vertical staircase is placed in a plastic cellar - metal or plastic. Using it is far from convenient. It is still normal for the young, but it is very difficult for the elderly. In addition, imagine how you will lower / raise bags of potatoes, carrots, beets. Banks are no better. How to raise or lower them so as not to break. Okay, you can think of something for the cargo. For example, make the simplest lift: block, rope, basket. Load supplies into baskets and lower them in this way.The problem has been partially solved, but going up and down the steep stairs is an unsolvable problem.

It is much more convenient if the ladder is placed at an angle, but in this case, a neck is needed for almost the entire length of the body. In most cases, a caisson for a plastic body is made to order. When placing an order, you can check if they can make a large neck. This should not affect strength in any way. The only possible consequence: the mass will decrease, which presses the caisson from above, saving it from being ejected. The way out is to make the plate slightly thicker on top.

There is one more option. Some manufacturers (Titan) have developed models of plastic cellars with an inclined entrance. They are, of course, much more convenient to use, but more difficult to install. And the price is even higher.

It is imperative to concrete a plastic cellar so that the walls do not float up or bend. Spreading with mastic on the outer walls will not replace plastic in terms of tightness and environmental friendliness compared to concrete, on which mold can grow.

In a plastic cellar, concrete is poured in order to load it. For backfilling, a 5: 1 dry sand-cement mixture is sufficient. This rule works if the plastic cellar is made of high-quality primary polypropylene. And if you wake up to mount cellars from recyclable materials, then of course then it is imperative to pour concrete on the sides and you can also put a metal frame inside. Since recycled plastic does not hold its shape under stress. By the way, these rules will help you when choosing a plastic cellar.