Cork floor: how to choose

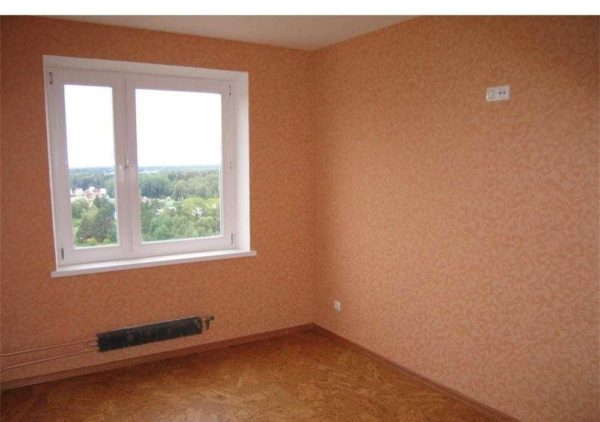

Floor covering is almost the most important element of interior decoration. It should be durable, beautiful, easy to clean. It is desirable that it be pleasant to walk on it and also so that your feet do not freeze. All these qualities are met by cork flooring. Until recently, cork flooring was very expensive. Not to say that now it is so cheap, but no longer so unattainable.

The content of the article

Types of cork flooring

Cork flooring is divided into two types according to the installation method:

- Adhesive, which fits on a special contact adhesive. It consists of a layer of pressed cork, on top of which a layer of cork veneer is glued, therefore this material is also called "cork parquet". It is rigidly bound to the base, varnished to improve performance. At a price per square meter, this type of coating is cheaper, but additional materials are required: glue and varnish. The installation process is quite complicated, so professionals often install the adhesive cork. As a result, a meter of such a finished coating is more expensive than with a lock.

- Castle. They resemble laminate in structure and method of joining, and this material is often called "cork laminate". A cork floor covering of this type is not connected to the base, it does not need an additional protective layer, since the top layer is a layer of varnish or PVC.

In terms of appearance, there is a cork floor with a traditional pattern in different colors. But not everyone likes this pattern, so collections have been developed that imitate wood, stone, sand, even lawn grass. The images are very realistic (photo printing), and they are applied directly to the cork layer - there is no intermediate layer, therefore such a floor is a product of natural ingredients. The top of the design is covered with a protective layer of polyurethane or polyurethane varnish. Here is a protective layer - not the most natural, but there are no alternatives to it - the wood is also covered with varnish or paint.

Pros and cons

The cork floor has many advantages. They are "quiet", elastic, resilient, absorb sound well, conduct heat poorly. This floor is pleasant to walk on both in winter and in summer. It is easy to clean - almost no electrification, dust does not "stick", the smooth surface is easy to clean. Some colors are so "non-marking" that debris is not visible. This is also a minus - a dropped small thing has to be searched for a long time.

It has few downsides - softness and high price. The softness is bad because the coating "crumbles" under the weight - furniture, heavy objects that have fallen, heels. But this disadvantage is compensated for when it is covered with several layers of varnish. And so that he does not get lost under the furniture, they choose it with wide legs, and also glue felt on them. When rearranging, you should also be careful - put plastic covers under the furniture legs. They distribute the load well.

Structure

Both types of cork flooring - castle and adhesive - are multilayer, but their composition is different. The glue plug usually consists of (bottom-up):

- Compensating layer of pressed cork chips.

- Natural cork layer - cork veneer (slate, photo printing).

In terms of thickness, this coating is thinner. It is more flexible. This determines the requirements for the preparation of the base: manufacturers recommend having an absolutely flat base. Otherwise, any pit or hump will eventually be visible.Practice has established that the differences can be significant (up to 5 mm), but they must be smooth. There are no "steps" or cracks, but a smooth gradual rise or fall is not visible. The difference in dimensions formed during installation is compensated for by the elasticity of the coating.

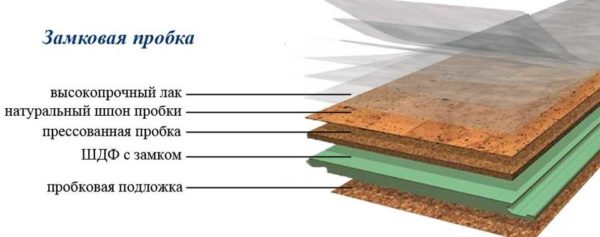

The chateau cork floor also consists of several layers:

- Pressed cork layer.

- HDF base (high density MDF) or moisture resistant PVC and quartz board.

- A layer of natural cork or cork veneer that can be photoprinted.

- A protective layer of varnish or polyurethane.

A cork floor with a lock is stiffer and very similar to laminate flooring. But only similar, since the laminate is pressed paper covered with a film with a printed pattern. This same material mainly consists of natural ingredients. It is the rigidity that determines the softer requirements of manufacturers to the base: there may be differences in height, but not more than 2 mm by 2 meters. You can also put a substrate under this coating, improving sound and heat insulation.

Lock or glue?

How do you choose which cork floor is better, chateau or adhesive? Each is not bad, but it has its own nuances. For ease of selection and a clearer presentation, the properties of coatings are summarized in a table.

| Glue plug | Lock stopper | |

|---|---|---|

| Moisture response | Not afraid of high humidity and "flood" | May swell when exposed to water |

| Base | It must be perfectly flat (according to the requirements of manufacturers, no drops at all) | Differences not exceeding 2 mm by 2 meters are allowed |

| Styling | Requires care or skill | Easy to assemble |

| Laying speed | Long process - spread the glue, wait until dry, adjust the cork, cover with 2-3 layers of varnish | A floor of 10-15 square meters is assembled in a day (no experience) |

| Maintainability | You can cut out the damaged fragment, replace and varnish | You can replace the damaged strip, but it is necessary to disassemble the covering from the wall to the place of damage |

From this we can conclude that it makes sense to lay an adhesive cork floor in rooms with high humidity (kitchen, bathroom) and high traffic (corridor, hallway). It can even be placed in unheated rooms or where there are high fluctuations in humidity and temperature (in baths, for example). In living rooms, the castle cork flooring feels great. The ease of installation speaks in its favor, but it is worth remembering that it is made on the basis of MDF and if water penetrates into the seams, the base will swell, the bar will deform. After drying, unfortunately, it will not return to its previous appearance. But in this it is no different from a regular laminate, so this is not such a big drawback in living rooms. You just need to clean up the spilled liquid in time.

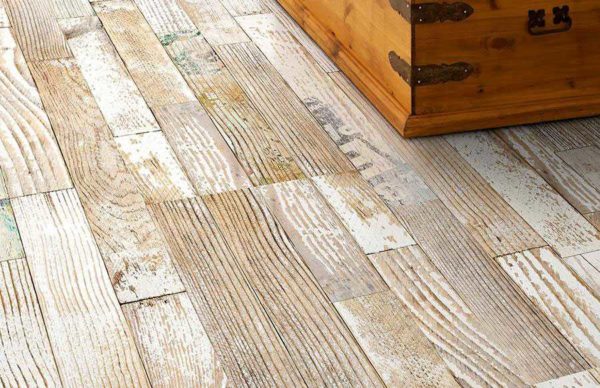

Photo-printed cork floor - option for interior style loft

This does not mean that the adhesive coating cannot be used in rooms. Very much even possible. Many people like it more, because with a good layer of varnish it has excellent strength - it does not get pressed through by heels and furniture. Also the castle. It can be covered with a layer of varnish on top (but not from all firms) and used in the hallway, kitchen or bathroom. They also cover it with a special oil with hard wax (OSMO type). The coating no less reliably protects against moisture penetration, but it is easier to apply and can only be renewed in some places. The downside is the high price, but its consumption for the locking plug is minimal - it is absorbed only into the joints.

Species and subspecies

Please note that there are different thicknesses of glued cork floors. The thinnest tile is 4 mm, it can be laid in rooms with low traffic, but it is better to use at least a 6 mm coating. A special subspecies is produced for the bathroom - large squares 10-12 mm thick and 148 * 148 mm in size. The thinner coating of the bathroom legs will simply be pushed through.

In addition, a glue plug is produced with the first varnish layer already applied.It costs, of course, more expensive, but the number of layers of varnish decreases - even one layer may be enough. Also, the front surface of this type of floor finishing material is protected from dirt, and the cork gets dirty very easily and all stains become visible after varnishing.

Modern cork coverings are not only in natural colors. There are with the printed image of wood of different colors, sand with shells, herbs ...

There are subspecies in the castle cork floor. First of all, it should be said that there is a moisture resistant version. The base of this material is not high-density MDF, but a special plate made of PVC and quartz, which is not afraid of water and high humidity. But this material does not have such a large assortment of colors and costs even more.

Any cork laminate has a protective coating. But it can be made of two materials - varnish or transparent PVC. Lacquer is more common, but PVC is stronger. Although, the laid coating with a varnish top layer can be re-varnished, having achieved high moisture resistance, but whether it can be done with a PVC coating is a question.

It is also worth considering when choosing an adhesive cork floor that after applying varnish, its appearance changes significantly. It becomes darker, the transitions are not so bright. To get a better idea of the end result, look for an interlock with the same color. As a result, you will be about the same.

Cork floor manufacturers and quality

There are two major manufacturers of floor cork on the market: CorkStyle and Wicanders. They speak well of South Korean manufacturers. Their prices are not so high, and the quality is quite normal.

Specifically in the selection process, pay attention to the cork conglomerate itself (pressed layer). To reduce costs, chips and other cheap material are added to it, but the quality of this product is already far from cork. It is tougher, wears out faster. Therefore, it is better to pay a little more, but choose with a cork layer, albeit a pressed one.

Those who are inclined to choose a glue cork for the floor should know that even very good manufacturers do not have ideal planks. They vary in size - plus or minus 1 mm in width or length - these are normal tolerances. They are compensated for by the elasticity of the material: when laid, the cork is slightly compressed so that the joints are tight. In addition, there are strips of different thicknesses. You cannot compensate for this, you have to sort through them, sort them. Thin ones are laid in one place where the transition will be invisible, for thick ones, the excess at the edges is sanded with sandpaper until the required thickness is reached.

- These are some of the colors in the traditional design

- Using direct photo printing (directly on the cork), any images are applied

- This is also a cork floor - in the nursery

- Very similar wood imitation

- You can even make a map on the floor

- If anyone likes pebbles better

- Option for loft style

In addition, there are defects on the front surface of the cork. It is lined with cork veneer, which is a natural material. It has depressions, ugly color changes, etc. There may also be production errors - veneer peeled off in some places or face polished to the substrate. Before starting the installation, all the tiles are inspected, the unsticked places are glued, the rest of the planks are used when laying in certain places. Read more about laying here, it is also described where to use these flawed strips.

Cork laminate - the interlocking cork floor has no such problems - the protective coating has already hidden all the flaws. But when choosing this material, pay attention to the reliability of the locks - in cheap materials, they are the main problem.