DIY home horizontal bar: drawings, diagrams, photos

To maintain physical fitness, not everyone has the opportunity to go to the gym, but exercise can be done at home. To strengthen the muscles of the arms, back and press, you can make a horizontal bar for the home. There are different designs - the simplest and more complex.

The content of the article

Types of horizontal bars

To maintain fitness, it is advisable to have sports equipment at home. The simplest of them is a horizontal bar. This is one or more small bars that allow you to train the muscles of the arms, chest, abs and back. You just need to find a suitable set of exercises.

For home (apartment)

In the house, it is usually easier to find a place for a horizontal bar. In an apartment, this is usually more difficult to do, so many are looking for options that take up little space, can be easily removed and installed: so that they can be stored, say, in a closet and hung only for the duration of classes. There are such models for indoor use:

- Wall mounted... There are different sizes and designs - from a simple crossbar at the corners to more complex designs for different grips and different muscle groups. They have a common type of fastening: powerful corners that are attached directly to the wall.

- Corner... One of the varieties of wall. The difference is clear from the name - they are attached to two adjacent walls forming an angle.

- In the doorway... Requires a minimum of time to manufacture, and even can be removable. Available in two versions:

- Installed in the doorway. This is usually just one bar. A more complex structure cannot be strengthened here anyway.

- Mounts above the door. A slightly more complex design that allows you to diversify your activities.

- Two small wall bars: one for chin-ups, one for bench press and corner bars

- 3 in 1 model

- In a doorway or in a narrow hallway

- Methods for attaching a removable horizontal bar in a doorway

- Ceiling mount

- Between two walls in a narrow corridor... This is a kind of horizontal bar that is installed in the doorway. It's just that it's longer.

- Ceiling... The type of installation is different: the structure is attached to the ceiling.

Which type to choose depends on the set of exercises that you plan to perform. For regular pull-ups, even a regular stick in the doorway is enough. On it, you can adjust the width of the grip within the width of the doorway. For more complex complexes, something more serious is required.

Outdoors

A street horizontal bar is usually a more complex design. At least two posts, dug deep into the ground, to which, in addition to the crossbar, beams and / or a crossbar can also be welded. There may also be an incline bench. This is the minimum for those who are serious about their form.

- There are very simple outdoor horizontal bars - two racks with a crossbar, there are whole complexes

- Universal version - with wall bars and devices for pumping all muscle groups

- Backyard mini sports complex

In general, you can hang a wall horizontal bar on the outer wall of the house - an option for summer training.

Choice of materials

Usually, a home horizontal bar is made of metal pipes. They come in round and rectangular (square) sections. Rectangular, with the same cross-section (diameter and diagonal) and wall thickness, have greater rigidity and carry a large load. But if the pipe is crumpled, then the rectangular one sharply refracts, and the round one bends slowly. To prevent this from happening, choose thicker walls (from 2.5 mm and more).The horizontal bar will turn out to be heavier, but it will be more reliable, it will be able to withstand heavy loads.

You also need to choose pipes for the horizontal bar for convenience. If we talk about exploitation, then it is more convenient to put a round one in the hand. But a rectangular one is easier to cook, since a round one requires a higher degree of skill. Even rectangular better "lays down" on the wall, its support area is larger. This is important for wall structures. Apparently, therefore, the frames and posts of domestic horizontal bars are made of a square (profiled) pipe, and the crossbeams are made of a round one.

As a rule, the diameter of the horizontal bar crossbar ranges from 27 mm to 32 mm.

Also horizontal bars for the house are made of wood. But since wood is not homogeneous, it is difficult to predict its behavior under stress. Considering that movement can be jerky, chances are high that the wooden bar will crack. So if you want to make a horizontal bar, it is better not to use wood.

A few words about the type of steel that can and should be used. You can make a horizontal bar for your home from an ordinary pipe - from black metal. After welding, it is cleaned to pure metal, treated with soil and painted. This is quite enough for use in a house or apartment. For outdoor horizontal bars, it is better to treat with an anti-corrosion compound after cleaning, then with primer, and then paint in two or three layers. If possible, apply powder paint. It has an uneven surface, does not slip at hand. Some types of hammer paints can have the same surface. They also give an unusual effect: uneven color. It looks very good on metal things.

You can also make a stainless steel horizontal bar for your home or street. It is hardly reasonable to transfer expensive material to the frame, but the crossbars can also be made of stainless steel. Just do not take pipes made of food grade stainless steel - they are made with thin walls, so they often do not withstand and bend. Get good alloy structural steel. It will not rust and will withstand heavy loads. But there is another point: the pipe may turn out to be too smooth, which is inconvenient. When gripping, hands can slip.

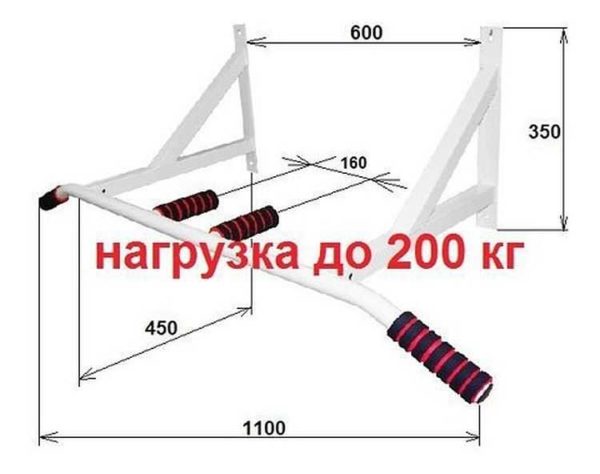

Schemes and sizes

Horizontal bar schemes are what is important. The pipe diameters and wall thickness are important. This is really important and the dimensions are approximate. They can change depending on the height and size of the person. Usually they are given under "average" height and average chest sizes. If your parameters are larger than "average", increase the size so that it is convenient for you.

Wall models

One of the most convenient and functional are wall horizontal bars. They are more cumbersome and complex in design, there are quite simple ones. Let's start with the harder ones.

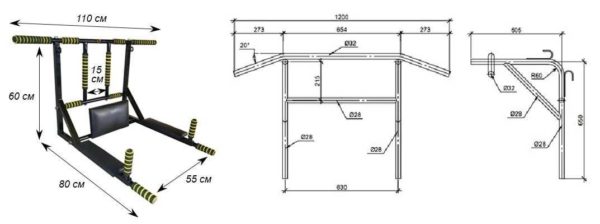

The figure shows a horizontal bar on which you can practice in two positions. In the picture on the right - a position for working out the press, on the left - for working out the arms, back and pectoral muscles. This design can be improved. In the diagram on the right, there are two bars that are used for narrow grip work. You can install additional crossbars for the middle, and use the extreme ones for "normal". A wide grip is provided by the handles sticking out on the sides. It is more convenient if they have a slope of the order of 30 °.

Turning over the horizontal bar is not always convenient, so another design was invented - with handles on the front bar. It is less massive and requires fewer pipes. But you will have to pump the press on another simulator. This does not provide such an opportunity.

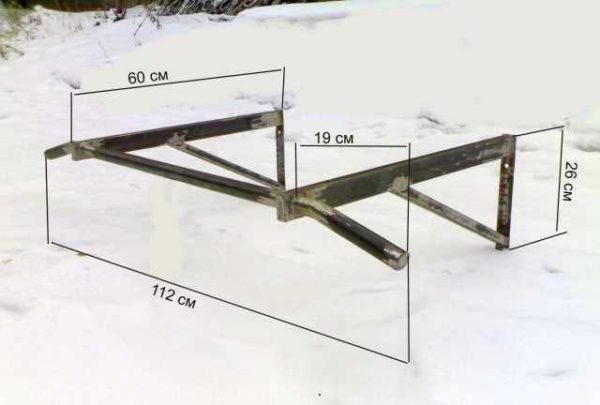

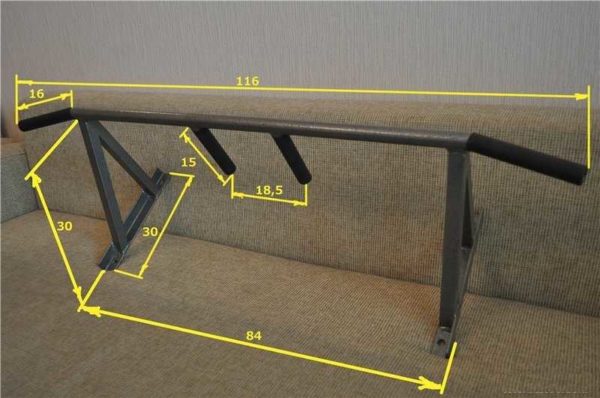

Despite the disadvantages, the above construction is repeated many times.It is simple, reliable, takes up little space, and therefore is popular. The dimensions are slightly adjusted, leaving the pipe diameters and the thickness of the corners unchanged or increasing the wall thickness. An example is in the photo below.

There is an even simpler construction. This is just one bar that you can only pull up on. But this design is one of the most compact. It can be hung over the doorway and it will not interfere, will not attract attention. It makes sense to make a horizontal bar of this design if there is no room for placing a more serious projectile or there is a wall bars.

Overdoor structures are among the most compact. Less space is occupied only by those that are installed in a doorway or between two closely spaced walls (in general, only a pipe is needed, under which special fasteners are made).

Horizontal bars for the yard

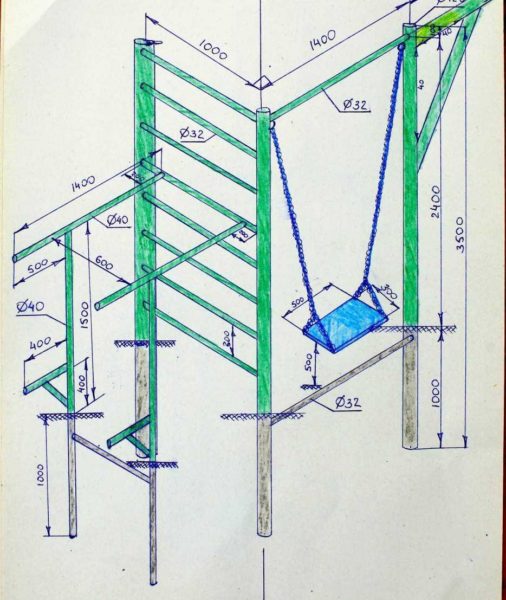

More complex structures are usually installed in the yard: there is no need to save space, therefore they make the model as comfortable as possible. At the same time, it is worth approaching the issue carefully: to make the horizontal bar reliable, you need pipes with a solid wall thickness, and they are not cheap. Therefore, since there are already racks and crossbeams, you can make a wall bar and a mount for a swing - so that both children can play and adults can train.

Please note that the racks are connected in pairs with jumpers. The lintel is buried in the ground and serves to stabilize the position under lateral loads. What else to look for is the depth to which the pillars are buried. If the ground is prone to heaving (clay and loam), it is advisable to bury it below the freezing depth. In central Russia, this is about 120-130 cm. In order for the racks to stand securely, pieces of pipes can be welded perpendicularly to the underground part. This will complicate the installation, but the pillars will definitely not loosen.

How to make a horizontal bar for an apartment with your own hands - photo report

Even for the most complex wall model, 2-2.5 meters of a profile pipe and about 1.5 meters of a round one are enough. To make a horizontal bar for your home with your own hands, a leaflet with the selected model and dimensions is pre-printed. For the frame, a profiled metal tube 20 * 30 * 3 mm was used, for the crossbeam and "handles" - the remainder of the curtain rod for Soviet-era curtains. The pipe is thin, but it still holds up. To begin with, using a grinder, I sawed the profile pipe into pieces of the required length.

There are no corner stops on the diagram, they are made "by eye". The angle is about 50 °. Then it's up to the little thing - to cook. With help inverter welding machine it's not too difficult. Moreover, the pipe has a thick wall: 3 mm is cooked normally.

The result is two halves of the frame in the form of the letter "G" - they need to be connected with jumpers. To make the frame racks parallel, we use strips that fix the parts at the same distance. At the same time, from the scraps of a stainless steel pipe, we weld the handles at the bottom, which we will hold onto when pumping the press.

For a tight abutment of a round pipe and a rectangular one, a semicircle is cut out in the rack with a grinder. I had to modify it with a file, but the fit is very good. It remains to scald.

To weld the handles for a narrow grip to the round pipe, we also form recesses in the pipe sections. It is more difficult to cook them - the pipe thickness is much less. And generally speaking, other electrodes are used for welding stainless steel... Due to a lack of experience, the seams turned out to be ugly, but without an obvious marriage.

Next, you need to bend the pipe along the edges. To do this, insert a rod of a smaller diameter into the pipe, take a gas burner, warm up the bend, bending it little by little. You need to bend it by 30 °.To do this, I drew a corner on the floor with chalk, bending it, checked along the drawn lines.

We put on an emery wheel on the grinder, clean the welding places. Then, in a circle with less grain, we remove plaque from the entire structure, additionally sanding the seams. Ready for painting. Spray paint was applied in three layers.

For wall mounting, hooks are made from a 15 * 4 mm metal strip. It was not easy to bend - holding a whole piece in the tongs, it was possible to bend it on both sides. The finished hooks were cut to length and drilled for the dowels. Used a drill with a diameter of 8 mm, reamed 12 mm under the heads of the fasteners. The hooks are cleaned and painted with the same paint.

Before making a horizontal bar, decide on the place where you will hang it. Not all spouses will calmly accept such an innovation ... Homemade horizontal bar 3 in 1 on the wall in two working positions

Almost everything is ready. It remains to make pillows for the shoulders. For the base, pieces of plywood were taken, on them - thin furniture foam rubber in two layers, covered with eco-leather with holes. For fastening leatherette used staples and construction stapler, but you can also use furniture nails if you don't have a stapler.

From operating experience: hooks on the wall should be made longer, for at least three dowels. And one more thing: the design has been improved - the handles for a narrow grip in the version shown in the picture are inconvenient, so another crossbar is welded on.

The homemade horizontal bar turned out to be heavy - 19.8 kg, but in this form it is more convenient.

In conclusion, a small entertaining video prank "Grandfather punishes the turnstiles." Be healthy!