How to build partitions from tongue-and-groove slabs (GWP)

When redeveloping an apartment or building a private house, you have to install new partitions. It is not so easy to find material for them. It should not create an excessive load on the floor, it should be reliable and have good load-bearing capacity. It is also desirable that the installation is simple and fast, and the price is low. There are not so many materials and technologies that meet these requirements. it plasterboard partitions and tongue-and-groove plates. In this article, we will talk about the tongue-and-groove.

The content of the article

What is this material and its types

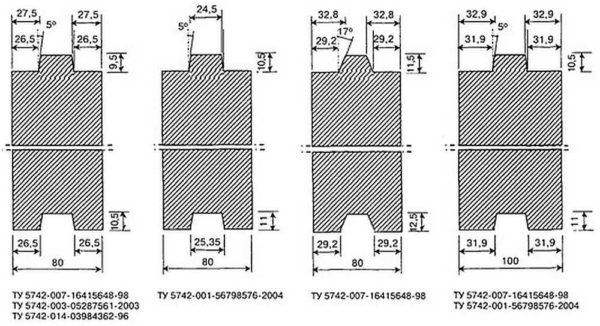

Tongue slabs (abbreviated as PGP) or blocks are large-format building material for the construction of partitions in the form of a slab, at the ends of which a ridge (spike) and a groove are formed. Hence this name - tongue-and-groove plates. They are:

- gypsum-based (cast plaster);

- from sand and quicklime, pressed under a certain pressure and steam-treated in an autoclave (silicate).

Plasticizers and hydrophobic (water-repellent) additives are added to the solution to improve the properties. Gypsum GWP has another name - gypsum boards. It is understandable: the gypsum solution is poured into molds. Here is the "source" of this variant of the name.

Moisture resistance and voidness

According to the area of use, tongue-and-groove plates can be designed for normal operating conditions (normal, standard) or for damp rooms (moisture resistant). Moisture-resistant for better identification, tinted greenish.

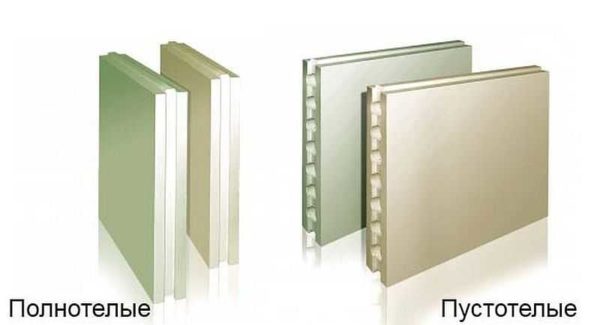

Both gypsum and silicate tongue-and-groove slabs are full-bodied and hollow. Corpulent, more durable, hollow due to lower weight create less stress on the floors. The choice between corpulent and hollow must be made based on several factors:

- Sound insulation characteristics... A monolithic material without voids conducts sounds better, so it is used if sound insulation will be made in a separate layer (the best option) or if it is not so important.

- Partition loads... If you need to hang shelves, furniture on the walls, fix some heavy objects, it is better to use a monolith.

- Floor or floor load... It is better to place less heavy (hollow) blocks on wooden floors or old wooden floors.

Considering several factors, sound insulation is the last thing to consider. It is possible to increase noise protection using a special mounting technology (on vibration-damping pads), as well as by making an additional layer of sound-insulating materials.

Specifications

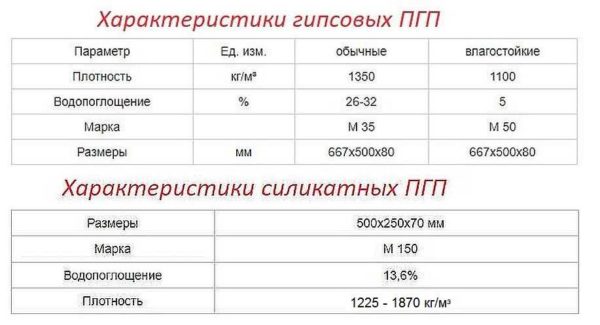

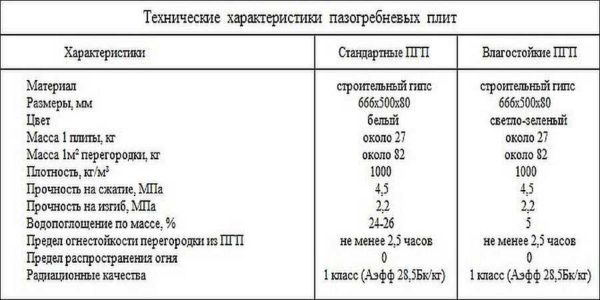

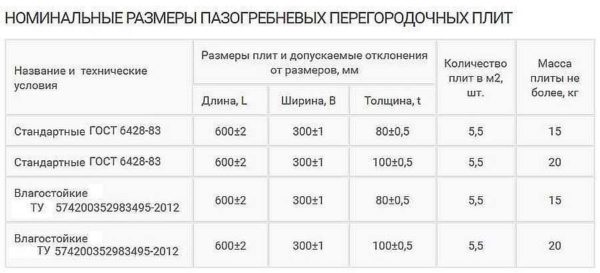

If we compare ordinary and moisture-resistant tongue-and-groove plates, the differences in characteristics are only in water absorption and strength. Moisture resistant, due to the large amount of hydrophobic additives, they almost do not absorb moisture. Due to the large number of these additives, they are more expensive, since these additives are expensive. At the same time, they increase the strength (M50 compared to M35).

By the way, you can check "without leaving the checkout" whether you really have moisture-resistant GWP or just standard green-colored ones. Just pour some water on the surface. Standard plates will quickly absorb it, and on water-repellent plates it will stand for a long time in a puddle.

If we compare gypsum and silicate partition blocks, the increased strength of the latter immediately catches the eye - M150 compared to M50 and M35. That is, the strength of silicate slabs is comparable to concrete of not the worst brand. If you are going to hang something very heavy on the partition, it is better to use silicate. Manufacturers also produce blocks with a thickness of 115 mm, which are called inter-apartment blocks.

How else do silicate boards differ from gypsum counterparts? The fact that in the standard version they have not so high absorbency. It is not as low as in moisture-resistant blocks, but this material can be used without problems in any damp room (13% versus 26-32%). The disadvantages of this material are more weight (with equal dimensions) and lower thermal insulation characteristics.

Silicate or gypsum?

If we compare the sound insulation characteristics of gypsum blocks and silicate blocks, the latter, with equal parameters, conduct sounds worse (40-43 dB for gypsum blocks and 48-52 dB for silicate ones). So for better sound insulation we choose silicate.

But silicate blocks of the same size have more weight and higher thermal conductivity (better heat conduction). The key in the choice is weight, since sound and thermal insulation can be improved with additional layers of special materials, but there is no way to reduce the weight of the partition. And if its mass is critical for overlap, nothing good can be expected.

How to build from tongue-and-groove slabs

In order for the partition made of tongue-and-groove blocks to be reliable and stable, certain conditions must be met:

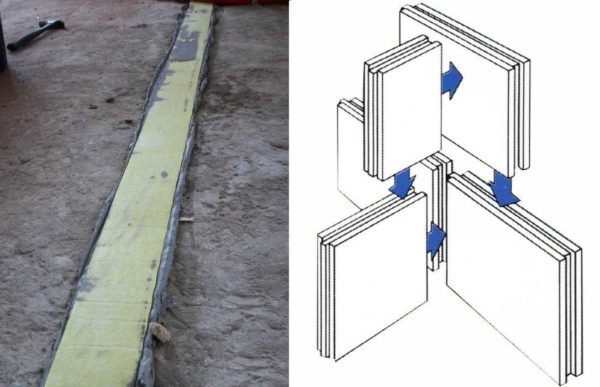

- Place blocks on a perfectly flat base with height differences of no more than 2-3 mm per meter. It must be aligned in all planes. On concrete bases, a leveling screed is poured (minimum thickness 3-5 cm), on wooden floors, a dry flat bar is laid.

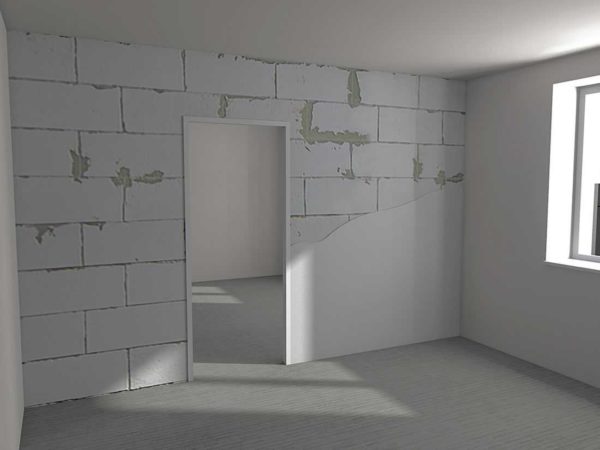

- Laying is carried out by analogy with brick - with a bandage in the middle. Special or tile adhesive is used. With silicate blocks, you can use a solution for masonry foam blocks.

- The partition must be strictly vertical. A deviation of even one degree leads to instability, so control at the usual building level is insufficient. Can be controlled laser level and / or a plumb line.

- The maximum height of the partition made of tongue-and-groove plates is 3.5 meters, the maximum length is 6 meters.

- A gap of 20-30 mm must be left between the top of the PPG partition and the ceiling. This gap is filled with polyurethane foam.

- To give more stability, it is advisable to strengthen the abutment with the ceiling by hammering in the pins and bricking them inside the blocks (not between the seams as the seams are very thin).

- The sound insulation of the tongue-and-groove partition is not too high. To make your life comfortable, use a cork or bitumen lining under the wall, and also sheathe the walls on both sides with plasterboard. This "pie" creates comfortable living conditions.

In general, you must strictly follow all the recommendations, strictly follow the technology. Then tongue-and-groove partitions do not differ in strength and reliability from brick ones, but are erected several times faster.

Markup

The laying of the partition from the tongue and groove begins with the marking. If you have a laser plane builder, everything is simple: you unfold the plane, draw lines on the floor, walls, ceiling. If there is no such tool, you will have to spend more time. A plumb line is required. The one that won't fit in a smartphone is not a measuring tool. Better to buy at a hardware store or make with twine and a center weight.

We draw the first line on the ceiling, using a plumb line we transfer it to the floor.By connecting the dots on the floor and ceiling, we get lines on the walls. As a result, a closed marking was formed to align the partition.

We examine the base on which we will lay the blocks. It should be perfectly aligned when viewed along the baffle line, and should not tilt forward or backward when viewed from across.

If there are door or window openings in the partition, they must also be marked. With doorways, everything is simple - we mark them on the floor. It is more difficult with window - you need beacons on the walls and ceiling.

Foundation preparation

As already mentioned, the base should be perfectly flat without tilting to any side. If there are deviations, fill in a leveling screed on the concrete floor (concrete grade not lower than М150). To do this, you will have to assemble the formwork into which the solution is poured. The minimum layer thickness is 3 cm. To obtain a guaranteed quality result, use a self-leveling compound. Just keep in mind that not too big errors "align themselves". You still need to manually distribute the composition. Just sweep with a spatula, accelerating the solution along the entire length, and small irregularities are leveled due to the increased fluidity of the material.

We cover the poured concrete with polyethylene, leave it for about a week. This is if the temperature in the room does not drop below + 20 °, during this time it will gain 50% strength. This means that you can work with it. If the temperature is lower, the period increases. At a temperature of 17 ° C and a little lower, it takes 2 weeks already ... We coat the even base with concrete contact - it will improve the adhesion of the base with the adhesive on which we will lay the GWP.

If the tongue-and-groove blocks will be placed on a wooden floor, the partition must pass over the beam - this time. Second, we level the base with a dry timber. It must be secured so that it is also horizontally aligned in all directions. We fasten the timber to the floor with nails or self-tapping screws. If there is a joint, we connect it in half a tree, additionally coating the joint with wood glue and fastening it with nails.

To improve sound insulation

The main disadvantage of gypsum groove partitions is not too high sound insulation. The situation with silicate blocks is better, but also not ideal. Therefore, we recommend laying vibration-damping tape around the perimeter of the partition. It is no secret that most of the sounds are transmitted through vibrations through the floor, ceiling and adjoining walls and elastic pads significantly improve the situation.

Under tongue-and-groove plates, you can use a strip of bitumen felt or corks with a density of 250-300 kg / m³. The width of the strip is slightly less than the width of the blocks. It is laid on a leveled base on the same binder that you will use to seal the joints between the plates. The solution is applied to the surface treated with concrete contact (after drying) with a layer of 2-3 mm. Lay the tape, rolling it with a roller, expelling air bubbles. The protruding solution is removed with a spatula. Thus, the tape is glued to the floor, walls, ceiling. Check the levelness with a bubble level.

Preparing slabs for installation

If silicate tongue-and-groove slabs are used, no preparation is required - they have no groove / ridge top and bottom surfaces. They are absolutely even (as in the photo below).

When working with a gypsum groove, first you need to decide whether you will place the blocks with a spike or a groove up. It is more convenient to work when the groove is directed upwards, but the reverse position is not an error either.

If you decide to lay the GWP up with a groove, a spike must be cut on all blocks of the first row. The most convenient way to do this is with a hacksaw. The resulting cut is uneven. We align it with a planer.

Note! The slab must be cut completely flat. It depends on how strong the wall of the tongue-and-groove plates will stand. And the cut tongue-and-groove plates must be of the same height.

The seam between the blocks does not exceed 2 mm, so that even small deviations are almost impossible to correct. Therefore, we align carefully and carefully. After leveling, the dust is swept with a brush and the wall can be erected.

First row

The sequence of actions when laying a wall of tongue-and-groove slabs is simple and very similar to a brick one. There are only a few features. Since the partition is usually adjacent to the wall, if a spike is turned to it, it is cut off with a saw, the surface is leveled with a plane, and dust is removed. Further, the procedure is as follows:

- A layer of mortar with a length slightly longer than the length / height of the block is applied to the wall and base (or laid vibration-damping tape). Putting a large layer is not worth it - it will still be squeezed out.

- The slab is installed, leveled, upset with a rubber mallet and moved close to the wall. Once again, control the vertical / horizontal. The squeezed out solution is picked up with a spatula.

- A mortar is applied to the end of the installed slab, and it is placed on the base - a little more than the length of the slab.

- They put the next block. With a mallet they "knock" him to the already established, achieving close contact. Controlling the position with the help of a level, they upset, achieving the same height with the already installed block. The correctness of the installation is controlled by a rule or level, an even bar. The tool is applied with the straight side to the already installed blocks - there should be no gaps along the entire length.

Thus, the entire row is built. The last slab usually needs to be cut. This could be the beginning of a doorway or just the last slab in a row. Its length should be 3-4 mm less than the remaining gap - the gap for the seam. Do not increase the gap - stability will decrease. For more confidence, the joint can be reinforced with a metal corner. Two or three corners for each row. It's enough.

Second and subsequent

The tongue-and-groove slabs are laid with an interval of seams - like bricks. The shift of the second row can be half or a third of the length. The best option is half. Cut off half of the whole plate, cut off the spike if necessary, install it. Further, the masonry is no different. The third row starts again with a whole block, the fourth with a half, etc.

After laying each block, check if it is correctly positioned. With such block sizes, the error accumulates very quickly. Therefore, we first check each delivered block with a level for vertical / horizontal. and then, putting the bar horizontally, grabbing the adjacent blocks and drawing from top to bottom, we look so that there are no gaps. We also check the absence of deviations in the vertical plane.

Angle

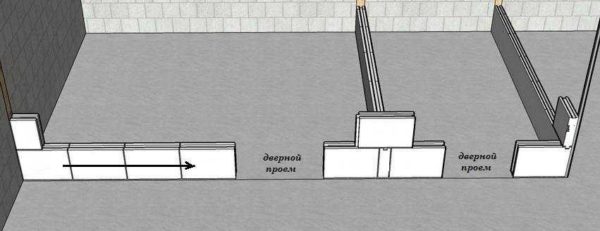

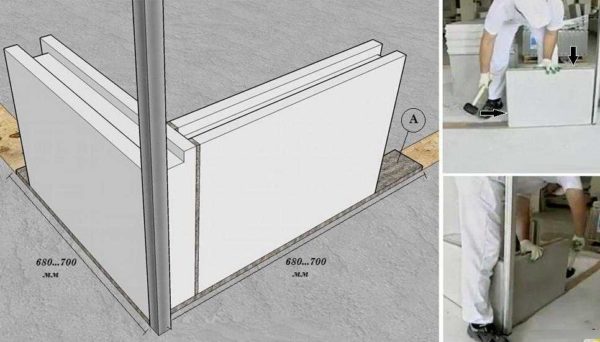

If the erected wall of tongue-and-groove blocks has an outer corner, we start laying from it. To make it easier to work, create a corner support. It can be a corner with fairly wide shelves or two boards connected at 90 ° C. We put the structure in place, check the correctness of installation, temporarily fix it to the ceiling and floor.

At one of the slabs we cut off the lateral spike, rest its edge against the set stop, align it, setting the direction with a mallet. At the second plate, we also cut off the side spike, apply glue to this edge, join with the side surface of the installed plate, knock it into tight contact (diagram in the figure above).

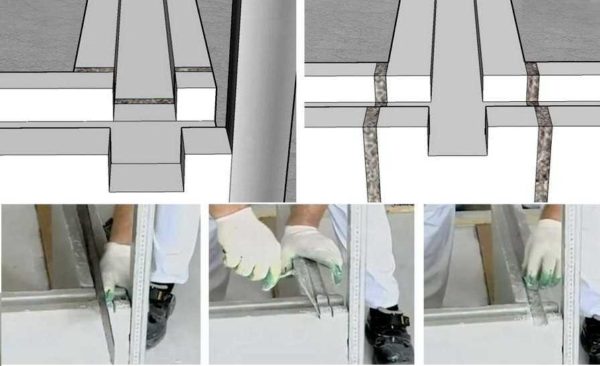

To install the second row, it is necessary to make a cut in the already installed plate under the lower spike of the next block. We take a hacksaw for metal, make cuts.Then, with the help of a wall chaser (a tool for working with foam concrete, but it is also useful for laying wiring in GWP) or any solid tool, remove the excess, align the groove, making it the same size and shape as the groove. We remove dust with a brush or a construction vacuum cleaner.

We put the second row starting from the other side - so that the seam is on the other side of the corner. Apply a solution to the end of the lower block. We take a half of the block, cut off the side spike, set it with the lower one in the prepared groove (the extreme right diagram in the figure below). It should also rest against the set corner. We carefully align the installed tongue-and-groove plates, checking the verticality and the absence of even the slightest deviations.

Branch

It is also necessary to consider the branch from the partition at a right angle. Partitions will be more reliable if they are made with a dressing (middle diagram in the figure). All three slabs that are installed have a lateral spike cut off. The joints are coated with adhesive, three blocks are fitted close to each other with a mallet. In this case, it is also necessary to control that the partition is perpendicular - that is, the angle is 90 °.

We build the second row so that the middle of the block is above the junction. To install it, you will also need to make a groove in the protrusions of the lower block. Further, these rows alternate.

There is another way to put a T-shaped partition from a tongue-and-groove - without dressing. To do this, simply lay out the wall (which in the letter T is the upper crossbar). To the finished wall, end-to-end, attach a second partition (left diagram in the figure above). To increase the reliability of the connection, metal reinforced perforated corners are installed at the junction.

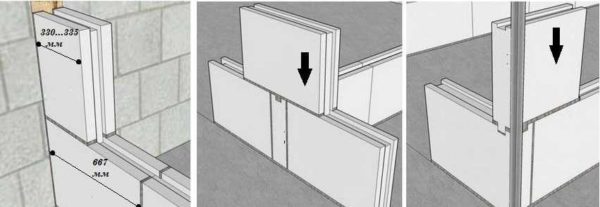

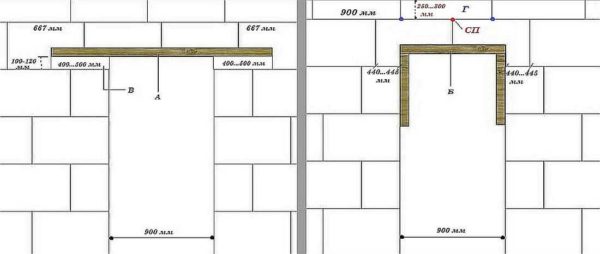

Doorway

The doorway in the wall of the tongue-and-groove plates can be made with or without a reinforcing beam. Without a reinforcing beam, it can be done if the width of the opening does not exceed half the length of the block. So a doorway with a width of 900 mm can be made without a beam, if the floor is made of GWP with a length of 900 mm. Moreover, the joint of the plates should be located almost in the middle. A slight offset (by 10 mm) is allowed, but the length of the whole part of the block to the right and left of the opening is not less than 445 mm.

At the time of installation, before the glue sets, the lintel above the door is reinforced with an emphasis (a board that is supported by a pole resting on the floor) or a structure assembled from boards as in the right diagram. In this case, first assemble a U-shaped jumper from the boards, fix it with self-tapping screws to the blocks located below (control the horizontalness of the jumper). Apply a block, mark how to cut. It turns out two L-shaped blocks of the same or almost the same size. Having applied the solution in the right places, they are installed.

If tongue-and-groove slabs are used 667 mm long, a reinforcing beam must be installed under an opening of more than 660 mm. For the manufacture of beams, you can use a metal corner, channel, reinforcement, metal strips of considerable thickness. It is possible to use dry wooden beams with a thickness of 50 mm or more (pre-treat with an antiseptic). The beam should protrude 400-450 mm beyond the doorway.