Concrete grade M300 B22.5: properties, composition, preparation

When pouring the foundation of a private house of almost any type, it is recommended to use concrete M300 B22.5. Its properties are optimal for the conditions of our country.

The content of the article

Characteristics of concrete М300 В22.5

According to the standard classification, concrete mortar M300 is classified as heavy concrete. In general, the classification using a strength grade (type M300) is outdated. It is more correct to apply new standards according to which concrete properties are described by compressive strength. This parameter is displayed by the Latin letter B and numbers, which denote the load limit that this type of concrete can withstand in compression. For concrete M300, the closest correspondence is B22.5. Until they get used to the new terminology, many try to use both. So they often say "concrete M300 B22.5", considering both classifications.

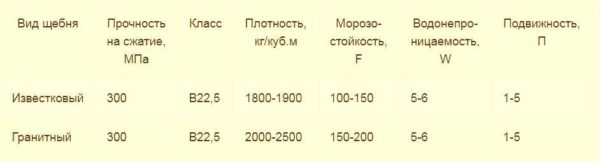

M300 B22.5 concrete can be on granite and lime aggregate. Depending on the type of aggregate, the mass of a cubic meter is 1.83-2.5 t / m³. This parameter is also called specific gravity or simply density. On crushed limestone, the weight of one cube of solution will be in the region of 1850 kg / m3. The minimum allowable value is 1800 kg / m3. Less weight can only be in violation of technology or when using low-quality filler. When using granite aggregate, the weight of a cube of concrete M300 will be about 2300-2500 kg / m³. The specific figure depends on the mobility of the given solution. The higher the mobility, the less mass. A solution with granite aggregate is also called granite concrete, on limestone - limestone.

Characteristics and technical indicators

M300 B22.5 concrete has the following characteristics:

- Frost resistance - F150-F200. That is, it can withstand from 150 to 200 defrost / freeze cycles without loss of properties.

- Water resistance - W5 - W8. If necessary, the parameter can be increased by using special additives.

- Mobility / ease of laying - from P1 to P5. This characteristic is often referred to as stiffness or fluidity. Hard concrete is more difficult to lay, but it cracks less when it shrinks. Fluid is used in reinforced elements so that the solution can fill all cavities around the reinforcement.

- Consumption for a layer thickness of 10 mm - 20-25 kg / m². That is, to fill a square meter of area with a layer 1 cm thick, you need 20-25 kg of mortar (depending on the filler and the hardness of the mortar).

- The minimum layer thickness is 16-18 mm. The specific figure depends on the fluidity of the composition.

- You can walk after 7-8 hours, provided that the work was carried out at a temperature of + 20 ° C.

As in the production of any concrete, in order for the mortar to gain the normalized strength, it is important to select high-quality components. If you are going to prepare it yourself, pay attention to the purity of the components, the freshness of the cement (not older than 3 months from the date of production). It is also very important to keep the proportions precisely. It is impossible to introduce more cement, water, additives. In most cases, this leads to a decrease in strength. So we maintain the proportions as accurately as possible. If we talk about GOST, then it allows deviations in the amount of 3-5% of the mass fraction. No more.

Application area

As can be seen from the technical characteristics, concrete M300 B22.5 has high strength, water resistance, and excellent frost tolerance. All this determined the area of its use. It is used:

- When pouring foundations of private houses and cottages.

- For blind areas around the house.

- For garden paths, making homemade path slabs.

- In the manufacture of concrete stairs.

- For concreting the site for the car.

- For monolithic walls and ceilings in multi-storey buildings.

- During the construction of the pool.

As you can see, concrete M300 B22.5 is also used in private housing construction. It is especially popular when pouring the foundation, but for this purpose it is better to order a ready-made solution. Especially when pouring slab foundation. Then you will definitely be able to fill the entire area without cold seams. In other cases, the volumes will not be so significant and you can make M300 concrete with your own hands.

Concrete proportions of 300 brands

M300 B22.5 concrete consists of crushed stone, sand and water. To improve properties (frost resistance and water resistance), to increase fluidity, additives can be added. The rest of the composition is stable.

Cement grade PC 400 is suitable for mixing - this is the recommended grade. Allowable - PC 500. It is desirable to buy cement produced no more than two months ago. After three months, it loses 20% of its strength, then even more. So the freshness of the binder is critical. Water is usually taken in relation to the proportion of cement and is 0.45-0.56 of its amount. The exact consumption can be selected only in relation to specific materials and especially the moisture content of the sand.

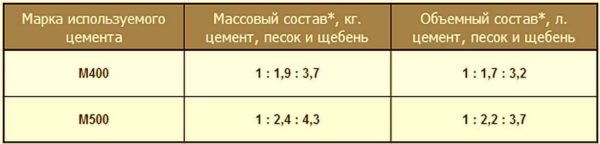

To make it easier to navigate, the proportions in the table are given in kilograms and volume fractions. When purchasing materials, kilograms are often needed; when mixing, volumetric fractions are usually used - buckets or shovels. Such a measure, of course, does not provide accuracy. If you are going to prepare a mortar for the foundation of a house, it is still better to accurately measure the components. Otherwise, no one knows what kind of strength you will get.

Components of concrete M300

Cement has already been mentioned. For self-made concrete M300 B22.5 to have the required strength, it must be fresh. The stale rate must be increased 2-4 times, but the result can only be guaranteed after testing. And this is a long time and hardly anyone will bother with it. So we are looking for a good cement manufacturer, packaged at the factory, indicating the release date.

Crushed stone

The use of lime and granite crushed stone is allowed. When using limestone, make sure that its strength is not lower than M600. Granite will have it higher anyway, so don't worry. Crushed stone should be at least two fractions, but it is better to mix all three: large, medium and small. Large about 30-35%, the rest in equal shares (medium and small). This will distribute the aggregate more evenly. A well-chosen composition of crushed stone allows increasing the strength of concrete to B25 with the same proportions.

Regardless of the type of crushed stone, it must be clean, free of dust and foreign inclusions. The presence of dust and clay reduces the strength of the concrete, and seriously. So we unload either onto a clean area or onto a piece of tarpaulin, other clean cloth or film. If the rubble is dirty, it is better to wash and dry it. But it takes time and if not, look for a clean one.

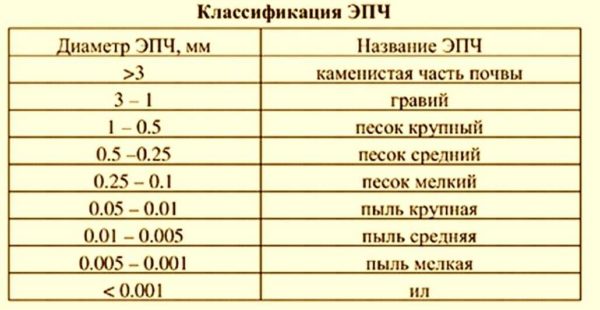

Sand

To prepare concrete M300 B22.5, river washed sand is needed. You can also use quarry, but precisely washed, so that there is a minimum amount of impurities. Clumps of clay are generally not allowed. If there is such a problem, the sand is pre-sieved through a sieve. Hold the sand in your hands and rub, if dust remains on your palm, it is better to rinse and dry it.

When making concrete, it is impossible to replace sand with fine granulation. It's not that strength. For a guaranteed result, it is better to take sand of several fractions: large and medium. Dusty (very fine) is not needed.

How to prepare concrete grade 300

Mixing concrete - it just seems like it's easy. In fact, even the order in which the components are booked matters. Uniformity is also important. So the components must be mixed thoroughly. Most often, the following order of laying materials is used:

- Throw in half the rate of rubble.

- Pour half of the water norm.

- Stir until evenly moistened.

- Sand and cement are added to achieve an even distribution.

- Throw in the remaining half of the rubble. Mix again.

- Add water.

This option is good if the sand is sown (no lumps), but it usually takes more time. If the sand was not sieved, first, dry crushed stone and sand are thrown into the pear and mixed well. In this case, the crushed stone will break all existing sand lumps. Then add cement and mix until uniform gray. After that they pour water.

In general, it is important to stir all components very thoroughly to obtain normal strength. You can check the readiness of the solution if you dump some of it and inspect the filler. Each pebble should be wrapped in a creamy mixture of sand, cement and water. And this mixture should be homogeneous, of the same consistency and of the same color. Having changed the order of the bookmarks a couple of times, the mixing time will be able to determine the best algorithm for yourself, because the only and correct one simply does not exist. The constituents are different for everyone, with different humidity. So we choose how to prepare the solution.