How to use Izospan correctly, which side to put in which "pies"

Many building structures use vapor barrier, wind protection, and waterproofing. One of the proven manufacturers of these products is an enterprise from Tver, which produces vapor-waterproofing materials and windproof membranes under the Izospan brand. The article describes the scope, technical characteristics and instructions for the use of Izospan of different types.

The content of the article

- 1 Isospan species

- 2 Izospan A: instructions for use

- 2.1 Rules for laying and installation of windproof vapor-permeable membranes

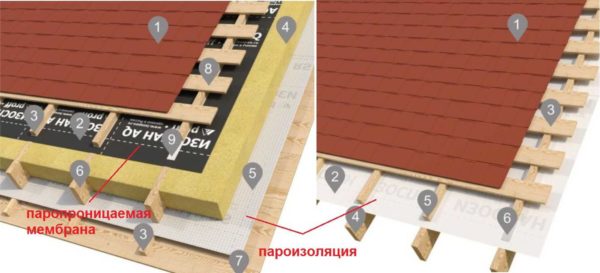

- 2.2 On a pitched roof, on top of insulation

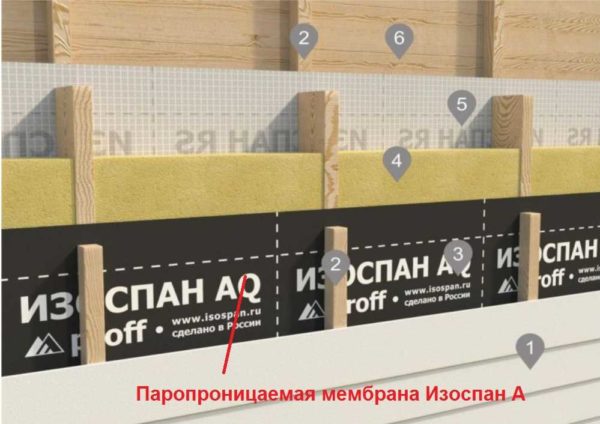

- 2.3 In the frame walls from the street side

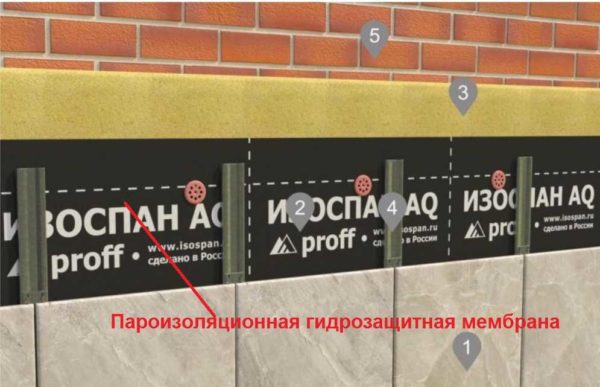

- 2.4 For wall insulation with mineral wool and for ventilated facades

- 2.5 Ceiling over a ventilated subfloor

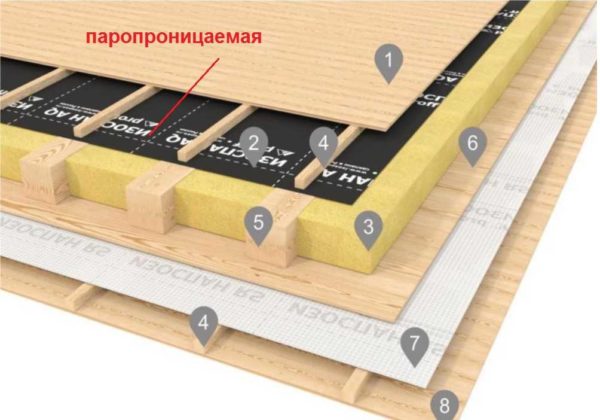

- 2.6 Interfloor and attic overlap

- 3 Instructions for the use of Izospan V, S, D vapor barrier

- 4 Vapor barrier with a reflective layer Izospan F

Isospan species

Let's start with what Izospan is. This is a trade mark under which the Tver enterprise Hexa produces nonwoven building materials - films and membranes for various purposes. In short, there are vapor barrier, windproof and waterproof roll materials. There are many materials, so the names, applications and features were tabulated. It's easier to navigate this way.

| Name | Appointment | Application area | Structural features | Properties |

|---|---|---|---|---|

| Izospan AQ proff | Vapor-permeable hydro-wind protection | Inclined roof (insulated and not insulated), frame walls, wall insulation, ventilated facade, attic and interfloor floors | Three-layer reinforced membrane | Protects from wind, allows steam to pass through, but retains moisture |

| Izospan AQ 150 proff | Vapor-permeable hydro-wind protection | Sloped insulated roof, frame walls, wall insulation, ventilated facade, attic and interfloor ceilings | Three-layer membrane | -//- |

| Izospan AS 130 | Vapor-permeable hydro-wind protection | Sloped insulated roof, frame walls, wall insulation, ventilated facade, attic and interfloor ceilings | Membrane | -//- |

| Izospan AS | Vapor-permeable hydro-wind protection | Sloped insulated roof, frame walls, wall insulation, ventilated facade, attic and interfloor ceilings | Three-layer membrane | -//- |

| Izospan AM | Vapor-permeable hydro-wind protection | Inclined insulated roof, frame walls, wall insulation, ventilated facade, attic and interfloor ceilings, internal walls | Three-layer membrane | -//- |

| Izospan A base | Vapor permeable windproof membrane | Basement ceiling above the ventilated subfloor | Windproof membrane | Protects from the wind, allows you to remove steam and moisture |

| Izospan A with OZD | Vapor-permeable hydro-wind protection with increased resistance to fire | Ventilated facades | Fireproof membrane | Protects from wind, permeates steam, but retains moisture and reduces fire hazard |

| Izospan AF + | Non-flammable wind protection and waterproofing does not impede vapor escape | Ventilated facades | Non-flammable membrane | Reduces heat blowout, removes steam, protects against moisture, does not burn and does not support combustion |

| Izospan B | Vapor barrier, waterproofing | Inclined insulated roof, frame walls, wall insulation, attic, basement and interfloor ceilings | Two-layer material (smooth on one side, rough on the other) | Does not allow steam, moisture, insulation particles to pass through |

| Izospan RS | Vapor barrier, waterproofing | Inclined insulated and flat roof frame and internal walls, attic, basement and interfloor ceilings, floors on concrete bases | Three-layer reinforced material | Does not conduct moisture in liquid or vapor state |

| Izospan B fix | Vapor barrier, waterproofing | Inclined insulated roof, frame walls, wall insulation, attic, basement and interfloor ceilings | Izospan B with two adhesive strips for easier fixing of panels | Does not allow steam, moisture, insulation particles to pass through |

| Izospan C | Vapor barrier, waterproofing | Inclined insulated roof, frame and internal walls, attic, basement and interfloor ceilings, floors on concrete bases | Two-layer material (smooth on one side, rough on the other) | Does not allow steam, moisture, insulation particles to pass through |

| Izospan RM | Reinforced steam and hydro insulation | Flat roofs, floors on concrete substrates | Three-layer material with an additional reinforcing layer | Does not pass steam, moisture in a liquid state |

| Izospan D | High strength steam waterproofing | Flat roofs, non-insulated sloped roofs, floors on concrete bases | Two-layer material based on woven polypropylene fabric | High resistance to steam and moisture, increased mechanical strength |

| Izospan D fix | High strength steam waterproofing | Flat roofs, non-insulated sloped roofs, floors on concrete bases | Izospan D with two adhesive strips for easier fixation of panels | High resistance to steam and moisture, increased mechanical strength |

| Izospan DM | High strength steam waterproofing with anti-condensation surface | Inclined insulated and non-insulated roofs, all types of floors, frame walls | Izospan D with anti-condensation properties | High resistance to steam and moisture, increased mechanical strength, no condensation |

| Izospan RF | Reflective vapor barrier, high strength waterproofing | Insulated pitched roofs, all types of floors, frame walls, warm floor | Multilayer material based on non-woven fabric with a reflective (shiny) layer | Reflects heat radiation, retains moisture in any condition |

| Izospan FD | Reflective vapor barrier, high strength waterproofing | Insulated pitched roofs, all types of floors, frame walls, underfloor heating | Multilayer fabric based on woven fabric with reflective (shiny) layer | Reflects heat radiation, retains moisture in any condition |

| Izospan FS | Reflective vapor barrier, waterproofing | Insulated pitched roofs, all types of floors, frame walls, warm floor | Non-woven fabric + metallized film | Reflects heat radiation, retains moisture in any condition |

| Izospan FB | Reflective vapor barrier, waterproofing for saunas and baths | Saunas and baths | Metallized Kraft Paper | Reflects heat radiation, retains moisture in any condition, tolerates high temperatures |

| Izospan FX | Reflective vapor barrier, waterproofing | Insulated pitched roofs, all types of floors, frame walls, underfloor heating, underlayment for parquet and laminate | Foamed polyethylene + metallized layer | Reflects thermal radiation, retains moisture in any state, has heat insulating properties |

| Izospan KL | Double-sided adhesive tape | Sealing vapor barrier joints | Adhesive layer - acrylic | Width 15 mm, length of tape in a roll 50 m |

| Izospan KL + | Double-sided adhesive tape | Sealing connections of materials, fastening them to building materials (concrete, plastic, wood, metal) | Adhesive layer - acrylate | Width 25 mm, length 25 m |

| Izospan SL | Double-sided connecting tape | Sealing joints of materials, fixing them to rough surfaces (stone, brick) | Butyl rubber tape | Width 15 mm, length of tape per roll 25 m |

| Izospan SL proff | Double-sided bonding tape with increased adhesion | For secure attachment and sealing of connections to other materials | Butyl rubber tape | Width 15 mm, length of tape per roll 22 m |

| Izospan FL | Metallized connecting tape | For connecting the vapor barrier to the reflective layer | Polypropylene with metallized layer | Width 50 mm, length 50 m |

| Izospan FL Termo | High temperature resistant metallized connecting tape | For connecting a vapor barrier with a reflective layer in baths and saunas | Aluminum tape with adhesive layer | Width 50 mm, length 40 m |

| Izospan ML proff | Heavy-duty single-sided tape | For bonding materials to building materials | Acrylate | Width 50 mm, length 50 m |

| Self-adhesive Sealing Tape (SUL) | Foamed polyethylene with adhesive layer | Protection against leakage of joints of materials with rafters on roofs | Foamed polyethylene | Width 50 mm, length 30 m |

As you can see, all Izospan materials can be divided into three groups:

- Wind protection. This is a group of materials Izospan A and varieties. These are materials that protect the insulation from blowing, retaining heat. At the same time, they remain permeable to steam, but do not conduct / do not pass moisture.

- Steam-waterproofing materials. These are Izospan B, C, R and several of their varieties. They do not allow moisture to pass through in any form.

- Energy-saving vapor-waterproofing Izospan F. Differs in the presence of a metallized layer, moisture does not pass in any form - neither steam nor liquid.

There are also connecting materials - connecting tapes one- and two-sided on a different basis. They are needed during installation, allow to avoid deterioration of characteristics at the joints. Some allow you to achieve tight connections.

How to distinguish by name

In the name of the materials, a key letter is put down, by which the group and basic properties can be determined. So Izospan A with all other indices denotes a vapor-permeable membrane. Izospan V, D, S - hydro-vapor barrier. The difference between the films of this group and the first is that these materials (B, C, D) do not allow steam to pass through. The materials of the first group (A) conduct it (steam), and only water is retained. The exception is Izospan A base. He does not hold water, and conducts steam.

The third group is also hydro-vapor barrier. It differs in that it has a metallized coating. The names of materials in this group contain the letter F: FD, FX, FS, FB, RF. They are used to retain heat more efficiently, as the heat rays are reflected from the shiny coating. But reflection is only possible if there is an air gap of 3.5 cm (or more) in front of the film.

After the first letter in the Izospan marking, there is often another second. It describes the special properties of a material. It can also be an abbreviation or a short word. For example, the presence of the letter M or S indicates the presence of reinforcement. The fix prefix means that there are glue strips along the edges, so there is no need to use an adhesive tape.

Izospan A: instructions for use

The Izospan A group of materials is a vapor-conducting windproof membrane that does not conduct water in a liquid state. Exception - Izospan A base. This membrane is just a windbreak. It does not impede the passage of steam and water. It is used in the ceiling over the ventilated façade, it is stuffed from the subfloor side. Protects mineral wool from blowing, does not interfere with the removal of moisture from the insulation.

| Name | Maximum tension in the transverse / longitudinal direction N / 50 mm | Withstands steam density, g / m2 * 24 h | Withstands water pressure, mm.w.st | Withstand ultraviolet light (without protective coatings) for at least months |

|---|---|---|---|---|

| Izospan AQ proff | 330/220 | 1000 | 1200 | 12 |

| Izospan AQ 150 proff | 270/160 | 880 | 1200 | 12 |

| Izospan AS 130 | 240/130 | 880 | 1200 | 3-4 |

| Izospan AS | 190/110 | 880 | 1200 | 3-4 |

| Izospan AM | 160/100 | 880 | 1200 | 3-4 |

| Izospan A | 190/140 | 2000 | 300 | 3-4 |

| Izospan A base | 170/100 | 1700 | - | 3-4 |

| Izospan AF + (NG) | 1400/1000 | 800 | 900 | - |

| Izospan A with OZD (RP-1) | 190/140 | 1800 | 300 | 3-4 |

To understand where and how best to use Izospan A, look at the characteristics. Once again: the film is not blown through (retains heat), removes steam, does not let water through. These properties are needed in the following constructs.

Rules for laying and installation of windproof vapor-permeable membranes

Vapor barrier materials are laid on vertical, inclined and horizontal surfaces. Despite the fact that the designs are different, the installation rules do not differ. Here's what to remember:

- On pitched roofs and walls, work begins from the bottom. On horizontal roofs - from one of the walls.

- The second layer of material is laid with an overlap. That is, one panel goes over another for at least:

- 10 cm on the walls;

- 15 cm on roofs;

- 15-20 cm in ceilings.

- Vertical joints (if any) are the same dimensions.

- All joints of the sheets are glued with double-sided adhesive tapes.

- Adjacent to the walls, the rafter system is also glued. It is recommended to use Izospan self-adhesive sealing tape for adjoining the rafter system. For joints - KL, for joining the KL + structure.

The task of vapor-permeable waterproofing and windproofing is to let steam through, but not to allow moisture to enter in a liquid state. Therefore, the strength of the joints is important.

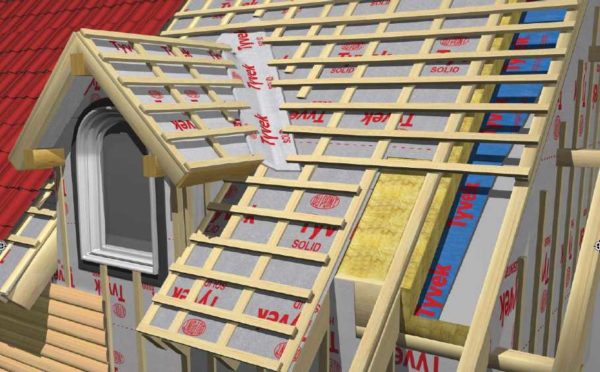

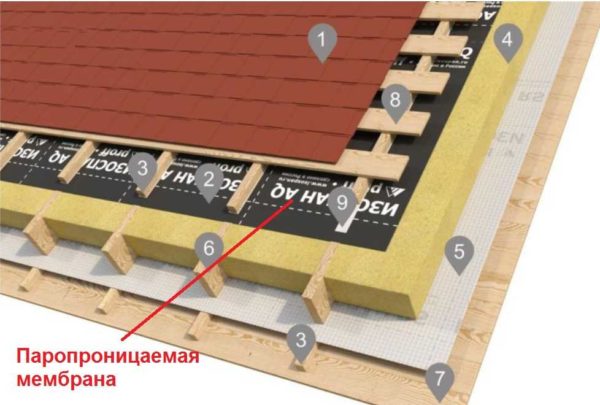

On a pitched roof, on top of insulation

The vapor barrier is laid on top of mineral wool, and covered with any roofing material on top. Let's see how everything works. Here it is necessary that the steam trapped in the insulation from the attic must be removed. At the same time, condensation and possible leaks did not get into the insulation. So you need to remove steam and not let water through. This is what Izospan A.

The membranes are unfolded with the "towards themselves" logo. It is better to lay it not in tightness, but with sagging. In this case, condensate, from which there is no escape on the roof, will drain to the center, and then into the gutter. drainage system... So it will dry out faster even in damp time, moisture will linger less, and it is less likely to get into the insulation.

On top of the vapor barrier, slats are stuffed along the rafters, and then across the crate for the installation of roofing material. With such a device and the presence of ventilation holes in the roof, the vapor barrier will be blown and dry.

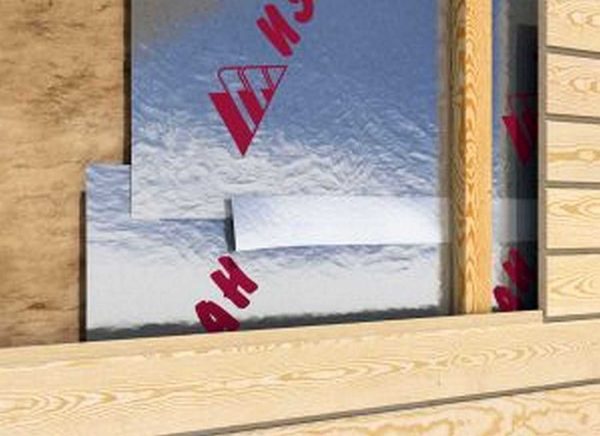

In the frame walls from the street side

Usually indoor humidity is higher than outside. And no matter how we protect the walls, steam seeps into them. These are the laws of physics. And since he hit the wall, he must be taken out. So here is the same task - to deduce steam. This can only be done from the street side. So Izospan A is also laid in the frame walls from the side of the street. All types of Izospan A can be used here, except for the "base".

When using Izospan A "in its pure form", it does not matter which side to lay it on. All other modifications - AS, AQ, AM - unfold so that the logo is outward.

For wall insulation with mineral wool and for ventilated facades

With external wall insulation, in ventilated facades, the situation is almost the same as with the frame. Some kind of moisture seeps into the wall from the room. Further, it penetrates into the insulation. Since wet mineral wool is a poor insulation material, care must be taken to ensure that this steam is quickly removed. In this case, it is necessary to protect the cotton wool from getting wet and keep warm to the maximum. That is, the problem is solved by all the same vapor-permeable membranes of the Izospan A.

Any vapor barrier for use in the case of external wall insulation, except for Izospan A with OZD, AF + and a base. The styling rule is the same - we unfold the logo towards ourselves. Izospan AF + is recommended for use in ventilated facades.If a metal structure is used, its strength will ensure that the vapor barrier will not break. If the ventilated facade is cladding on wooden beams, Izospan AM, AS and AQ in any of the options may well be suitable.

Ceiling over a ventilated subfloor

The ceiling over the ventilated plinth insulated with mineral wool has its own characteristics. First and foremost, for the circuit to work, the subfloor must be ventilated. It means that there must be air vents in the foundation... And they must be open even in winter, otherwise you will have wet insulation and cold in the house.

How does such a cake work? From the side of the house, moisture and steam seep into the insulation. If you just knock out the insulation with a net or slats, the wind walking underground will do an excellent job of removing moisture. But at the same time, it will carry away the heat and gradually take out the particles of mineral wool, reducing its thickness. To get rid of blowing out heat and insulation, use Izospan A vapor barrier A base. It allows steam and moisture to pass freely in both directions, but does not let the wind through.

Such an objection may arise. Moisture from the soil will evaporate and enter the insulation. Under certain conditions, it condenses on the membrane, which causes the insulation to get wet. Is it better to use a vapor barrier with waterproofing properties? No. It won't work. If the membrane does not conduct moisture, then the one that condenses or gets into the insulation will remain there. Because it won't get hot enough to evaporate and be discharged as steam. In a couple of years, you will have bags of water hanging from the ceiling and completely wet and unusable insulation.

And to reduce the evaporation of moisture from the soil, a dense film is placed in the underground, a layer of sand (any, but without clay and dust) is poured with a layer of 5-10 cm on it. The film retains most of the moisture, and the sand works as an adsorbent, absorbing the fallen condensate. It (sand) is also dried by the walking wind.

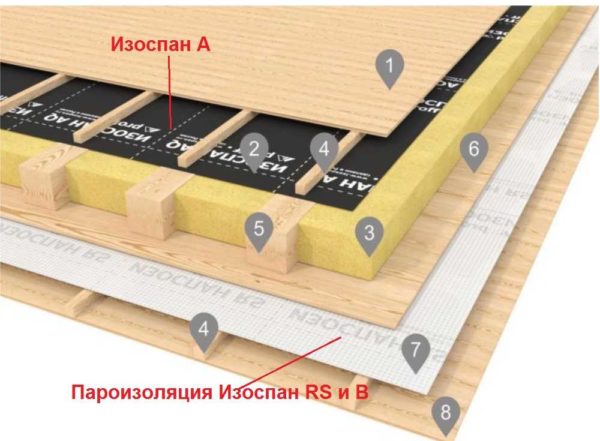

Interfloor and attic overlap

In the ceilings, steam enters from below, and should be discharged from above. Therefore, a vapor barrier is placed at the bottom to protect against moisture, and a vapor-permeable wind barrier is placed on top. In this cake, it additionally protects against the penetration of mineral wool particles into the room. Putting Izospan all the same - the logo should be facing you.

In the interfloor overlap, to reduce the cost, vapor-permeable Izospan can be replaced with non-woven material (any type of geotextile). Its main function here is to protect against the penetration of small particles of mineral wool into the air. But you can do this only if the flooring is a sheet material in two layers, and in a gap between the seams. Otherwise, moisture can seep out and then just a non-woven material will not protect the insulation from getting wet.

In the attic floor, such a replacement is not considered at all - here it also needs to be protected from heat weathering. So wind protection is essential here.

Also note that the vapor barrier is attached to the beams with counter-rails. And on them the flooring is already laid. Counterrails are needed to create a ventilation gap, which is a prerequisite for moisture evaporation. It is important.

Instructions for the use of Izospan V, S, D vapor barrier

Izospan vapor barrier films are at the same time waterproofing. They do not allow water or steam to pass through. What is the difference between Izospan A and B? The fact that B does not let steam through, A lets it through. This is short.

Made from different materials. There are films, nonwovens and fabrics made of polyethylene and polypropylene. Fabric-based materials have very high strength characteristics. Their use is justified in places where they can be subjected to high mechanical stress. Technical characteristics of Izospan vapor barrier films are given in the table.

| Name | Maximum tension in the transverse / longitudinal direction N / 50 mm | Vapor permeability | Withstands water pressure, mm.w.st | Withstand ultraviolet light (without protective coatings) for at least months |

|---|---|---|---|---|

| Izospan RS (rs) | 413/168 | no | 1200 | 3-4 |

| Izospan B and B fix | 130/107 | no | 1200 | 3-4 |

| Izospan S | 197/119 | no | 1200 | 3-4 |

| Izospan RM (rm) | 399/172 | no | 1200 | 3-4 |

| Izospan D (D) и D fix | 1068/890 | no | 1200 | 3-4 |

| Izospan DM (DM) | 700/650 | no | 300 | 3-4 |

The main task of these materials is to cut off the steam from the insulation as efficiently as possible and at the same time provide protection from moisture. A "side" but important effect is protection against penetration of mineral wool particles into the indoor air. It is used in the construction of walls, ceilings, on the roof, when installing a concrete floor. Vapor barriers are often part of the "pies" above, simply because they do other things.

Vapor barrier installation rules

The main task when laying vapor barrier films is to achieve as complete tightness as possible. It is necessary to let as little steam as possible into the insulation. We make all connections reliable using sealing and connecting tapes. The basic rules for vapor barrier do not differ from those described above:

- On the walls and roof, we start from the bottom.

- The next canvas enters the first by 10-20 cm.

- We make vertical joints with an overlap of at least 20 cm.

- All connections are glued with double-sided tape.

- The adjoining to building materials is done using assembly and connecting tapes.

- When used for flat roofs and in ceilings, the vapor barrier is installed on the walls and sealed there.

In addition to gluing the joints of the canvases, it is also important to use even strips-bars for the final fixing of the material. They tightly press the material, sealing at the same time the holes that the fasteners invariably pierce.

Pitched roofs - insulated and not insulated

Pitched roofs can be insulated or cold. In any case, a vapor barrier is installed on the side of the attic. She does not let steam into the insulation and this is her main task for this case. But Izospan for insulated and non-insulated roofs is different:

- for an insulated roof, it is better to use RS, B or B fix, they are distinguished by their strength (RS is stronger);

- for non-insulated - D or D fix, DM (DM is stronger than just D).

Izospan RS and B films have one rough side and the other smooth. So, Izospan B and RS must be turned with the rough side into the room. We unfold the smooth one to the insulation or roofing material.

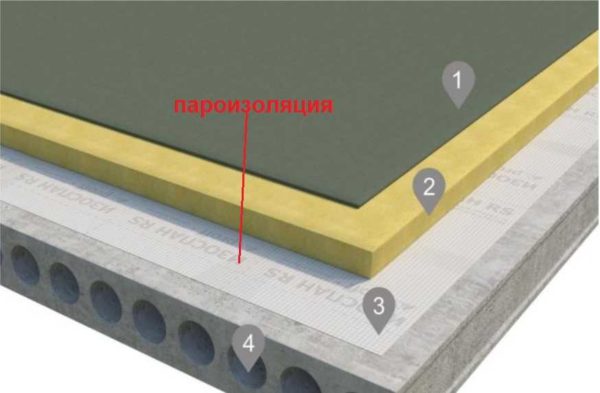

Flat insulated roofs

When insulating a flat roof, the vapor barrier is placed on the ceiling under the insulation. The task of this layer is twofold. On the one hand, do not let steam into the insulation, on the other, cut off moisture from the overlap in case of a leak.

In this case, it is recommended to use Izospan D and RM, RS. They have sufficient strength to withstand the loads that will necessarily arise when laying insulation.

Izospan B: instructions for use for walls

In the pie of frame walls, the Izospan V vapor barrier is installed from the side of the room. The task of vapor barrier is to let the steam into the insulation as little as possible. What gets into it (and will definitely get) will be displayed, since there is a vapor-permeable film Izospan A outside. But the less moisture there is, the better.

In this case, Izospan RS (RS) and B are recommended for use. The strength of RS is required only if you plan to take a break from work and the cladding on the walls will be mounted after a while. The smooth side of Izospan B goes to the insulation, the rough side is directed into the room. This is the basic rule.

Please note that in the diagram Izospan B is nailed to the racks with strips, and sheet material for wall cladding is mounted on the battens.This option is good, since it allows you to isolate the holes that the fasteners make with the help of a strip. There is another option - you can attach the film to the racks using stapler and staples with wide backs. The disadvantage is that the rack will not be visible and it is not clear where to attach the sheet material. But the option is possible, although not ideal.

Attic and intermediate floors

The vapor barrier in the wooden floor pie is needed from the side of the lower room. Looking from the bottom up, the sequence is as follows:

- ceiling filing;

- vapor barrier (Izospan B);

- rough ceiling;

- insulation between the beams;

- vapor-permeable film (Izospan A);

- floor laid on a counter-rail.

How does the vapor barrier work in this pie? It does not allow vaporous moisture to pass from the room to the insulation. In case of a leak from above, it will also retain moisture, but this is an emergency and the water will not hold for a long time.

Which side to lay Izospan B in in this case? Rough side to the room, smooth side up. When installing, try to damage the panel as little as possible. If a hole has formed somewhere, we seal it with tape. Better branded, but you can also just good, with a high-quality sticky layer.

Basement overlap

The basement floor is built according to a completely different logic. Here the steam will flow from top to bottom. From a warm room with humid air to a cooler, drier subfloor. And so that moisture penetrates into the insulation as little as possible, we put a vapor barrier on it (thermal insulation). The steam that has got into the insulation will either fall on the ground in the form of drops, or will be carried away by the wind in a vaporous state.

Izospan B and RS are recommended for use. When laying, we turn the rough side to the insulation, the smooth one looks into the room. The films are laid on beams, fastened with strips - counter-rails. The flooring is already being laid on them.

For better heat saving, vapor barrier materials with a metallized layer can be used: RF, FS, FD, FX. In this case, the thickness of the counter rails is at least 35 mm. This is the smallest clearance that allows effective heat reflection.

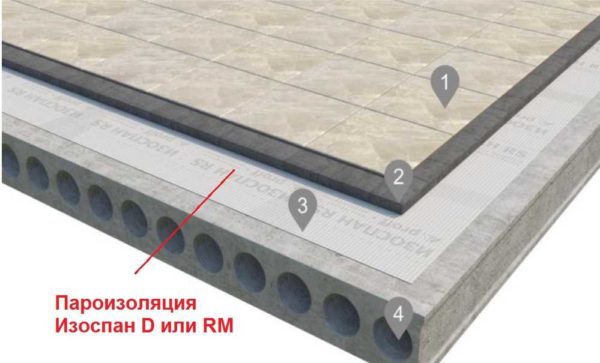

Screed on a concrete base

If it is necessary to level a concrete slab, a screed is often used. So that the water from the solution does not go into the ceiling, it is advisable to use waterproofing. It can be a coating or roll material. The cheapest is film. But you will have to walk on it and it is unlikely that it will remain intact. Especially if the screed is reinforced. Can a screed be cast without a film? If you are not afraid to flood your neighbors from below, then you can. Or if you use a coating waterproofing. Without it, most likely, the screed will not have the required strength. A certain amount of moisture is required to form a cement stone. And it will go partly into the slab, partly seep through the cracks. What the result will be is unknown. Accordingly, it is desirable to use a film.

It is recommended to lay Izospan D (D) or Izospan RM (RM) vapor barrier under the screed on a concrete base. These are waterproofing materials of increased strength. Which side to lay these materials does not matter. But Izospan D has a very high strength and it makes sense to use it only if the reinforcement is laid. RM is sufficient for a screed without reinforcement.

If there are significant depressions at the base, it is better to close them up; it makes sense to cut off protruding humps. This will not only increase the chances of preserving the film, but also make the screed thinner. And this is a significant savings.

Vapor barrier with a reflective layer Izospan F

The third group of materials is vapor barrier films with a heat reflection effect. They differ in that the outer layer is a metallized film (lavsan or polypropylene).They can be used instead of similar materials (vapor barrier) in all the above structures. If there is an air gap, the material can reflect heat radiation back into the room.

| Name | Metallized film type | Maximum tension in the transverse / longitudinal direction N / 50 mm | Vapor permeability | Withstands water pressure, mm.w.st | Withstand ultraviolet light (without protective coatings) for at least months |

|---|---|---|---|---|---|

| Izospan RF | polypropylene | 450/300 | no | 1200 | 3-4 |

| Izospan FD | polypropylene | 800/700 | no | 1200 | 3-4 |

| Izospan FS | polypropylene | 300/330 | no | 1200 | 3-4 |

| Izospan FB | lavsan | 350/340 | no | 1200 | 3-4 |

| Izospan FX | lavsan | 176/207 | no | 1200 | 3-4 |

The energy-efficient Izospan F vapor barrier is installed from the side of the room. When installing, we turn the shiny side into the room. The use of this group of materials can reduce heating costs by about 10%, but there is still debate about this: not everyone believes in it.

The second area of application of Izospan F is a substrate for finishing floor coverings. It is recommended to use Izospan FX under a laminate, parquet board, film heat-insulated floor. It is foamed polyethylene with a thickness of 2-5 mm with a glued metallized film. In addition to reflecting heat, it is also thermal insulation. Any other material in this group can be placed under all other coatings.

Using Izospan F in the underfloor heating system

When laying the floor heating system in the screed, the cake remains the same. Only pipe or cable is added. But they must be laid according to a certain pattern, so a metal mesh is also needed. Tied to her water floor heating pipes or electric heating cable.

In order not to warm the ceiling to the neighbors from below, it is advisable to direct the heat up as much as possible. To solve this problem, a heater is placed on the slab, and waterproofing with a heat-reflecting effect is placed on it. In this case, the material does not allow water to enter the stove and reduces heat loss during operation. For underfloor heating it is recommended to use Izospan RF, FX, FD, FS.