Dimensions of polypropylene (PPR) pipes: diameters and wall thickness according to GOST

The fact that metal pipelines are being replaced with plastic ones is not news for a long time. Usually they just decide which material to choose. Polypropylene is one of the best, although it is not without its drawbacks. What can be the diameters of polypropylene pipes, for which systems they are intended and how to choose a diameter. Read about all this below.

The content of the article

- 1 Polypropylene properties

- 2 Types and purpose

- 3 Pressure classification

- 4 Marking of polypropylene pipes

- 5 Diameters of polypropylene pipes: assortment according to GOST R 52134-2003

- 6 Standard diameters of polypropylene pipes and wall thickness depending on the maximum pressure in the pipeline

- 7 Connection method

Polypropylene properties

Although polypropylene is the least dense of all plastics, it is more resistant to abrasion, it tolerates heat better, begins to soften only at 140 ° C, is chemically resistant, and almost does not crack as a result of corrosion. The material is plastic. At loads not exceeding the limit, it stretches, and then returns to its previous shape without any changes in properties and characteristics. So it's a really good and safe option. Pipelines are made from polypropylene pipes at food enterprises.

An additional plus - polypropylene pipes are easily connected - they are welded... In general, not only plumbing and heating are made from polypropylene. This material can be used as a frame for greenhouses, country furniture and a bunch of other useful things.

As you can see, the diameters of polypropylene pipes are different. And that's not all. There are still up to 1600 mm

There are two disadvantages to polypropylene: high thermal expansion and reaction to oxygen and ultraviolet light. And with that, and with another learned to fight. In order for polypropylene to carry UV rays and light, stabilizers are added. Reinforced pipes are made to reduce thermal expansion. But even with reinforcement, the increase remains large and expansion joints must be installed in the pipelines.

Another disadvantage of polypropylene pipes is that they become brittle at low temperatures. Some species begin to crumble at -5 ° C, others at -15 ° C. So outdoor polypropylene pipelines require UV protection and insulation. Therefore, they probably prefer to bury them.

Types and purpose

Polypropylene pipes can be single-layer and three-layer. Single-layer is used for water supply, sewerage, ventilation and other pipelines with a temperature of the transported medium no higher than + 45 ° C.

Three-layer PPR pipes are reinforced. Reinforcement is designed to reduce the amount of thermal expansion and nothing more. PPR pipes are reinforced with fiberglass and foil. Those with glass fiber are suitable for hot water supply, provided that the water temperature does not exceed 80 ° C. For heating and systems where water can be heated above 80 ° C, foil-reinforced polypropylene is used. Foiling may not be continuous. For such pipes, the permissible temperature of the transported medium is + 95 ° C.

Can polypropylene pipes be used in underfloor heating systems? I guess, yes. The coolant temperature does not rise above + 45 ° C, which is quite acceptable even for single-layer ones. But due to the large thermal expansion, PPR pipes for underfloor heating are not the best option, even reinforced with foil. There are more stable options and not more expensive.

Pressure classification

Since a certain pressure is created in the pipeline for transporting the medium, polypropylene pipes also have such a classification. There are four categories:

- PN10. Working pressure 10 bar (1 MPa), maximum temperature + 45 ° C. For cold water and low pressure systems.

- PN16. Withstands pressure up to 15 bar (1.5 MPa), temperature up to + 60 ° C.Also for cold water, but can be installed in high-rise buildings.

- PN20. Pressure 20 bar (2 MPa) and heating up to + 75 ° C. Usually these are reinforced pipes, but with a small wall thickness. Used for hot water supply.

- PN25. Strongest pipes. Working pressure 25 bar or 2.5 MPa, continuous heating up to + 95 ° C. It is exclusively reinforced, with a thick wall. They are used for hot water supply with unstable pressure (in high-rise buildings) and for heating distribution.

The presence of reinforcement is visible on the cut. To make the fiberglass visible, it is tinted. Any colour

If we talk about which PPR pipes withstand what pressure, then single-layer (without reinforcement) can be used up to PN20. The difference in wall thickness can be seen from the table. The outer diameters of polypropylene pipes do not say anything (first column). The same external dimension can be designed for different pressures. It depends on the wall thickness and the presence / absence of reinforcement. So pipe marking is a must. The pressure class is indicated there.

| Outer diameters of polypropylene pipes, mm | PN 10 | PN 20 | PN 25 | |||

|---|---|---|---|---|---|---|

| Inner diameter, mm | Wall thickness, mm | Inner diameter, mm | Wall thickness, mm | Inner diameter, mm | Wall thickness, mm | |

| 16 | - | - | 10,6 | 2,7 | - | - |

| 20 | 16,2 | 1,9 | 13,2 | 3,4 | 13,2 | 3,4 |

| 25 | 20,4 | 2,3 | 16,6 | 4,2 | 16,6 | 4,2 |

| 32 | 26,0 | 3,0 | 21,2 | 5,4 | 21,2 | 3,0 |

| 40 | 32,6 | 3,7 | 26,6 | 6,7 | 26,6 | 3,7 |

| 50 | 40,8 | 4,6 | 33,2 | 8,4 | 33,2 | 4,6 |

| 63 | 51,4 | 5,8 | 42,0 | 10,5 | 42,0 | 5,8 |

| 75 | 61,2 | 6,9 | 50,0 | 12,5 | 50,0 | 6,9 |

| 90 | 73,6 | 8,2 | 60,0 | 15,0 | - | - |

| 110 | 90,0 | 10,0 | 73,2 | 18,4 | - | - |

Note that the wall thickness in the third column - PN25 - is less than the previous ones, although the pipes are designed for higher pressures. It's not a mistake. It's just that the pipes are only reinforced. And in the previous two categories, the wall thickness and diameters of polypropylene pipes without a reinforcing layer are indicated.

Marking of polypropylene pipes

As already mentioned, by the outer diameter it is impossible to determine what pressure the pipe is designed for. Moreover, it is also difficult to determine the type of material. Therefore, all this information is indicated in the marking that is applied to the pipe. It is repeated approximately every meter, so it is simply unrealistic not to see it.

The name of the company or its logo is usually put in the first place. It is better not to buy anonymous pipes But there is also a danger of getting fake if the company is well-known. It is necessary to study the logo well and buy only if there is a complete match. The following information is indicated below:

- The material from which the pipe is made. For polypropylene, this is PP. Reinforcing material may also be indicated.

- If it's aluminum it costs AL.

- Fiberglass - GF.

- Fiberglass composite material - PPR-GF.

- Next comes a layer-by-layer listing of materials. For example, as in the photo PP-R100 / AL / PP-R100. It also indicates the type of polypropylene. There may be such designations:

- PP-R100. These are pipes for pipelines with temperatures up to 100 ° C.

- PP-B80. Sewerage pipes with a temperature of the transported medium + 70 ° C.

- PP-R80. For cold and hot water supply, temperature up to 100 ° C.

- Dimensions of polypropylene pipes in millimeters or inches (if imported). The outside diameter is indicated first, then the wall thickness. Read about the conversion of inches to millimeters here.

- Pressure class: PN10, PN20, PN25.

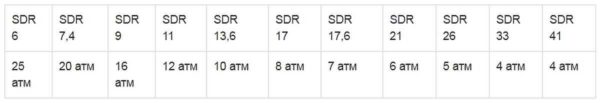

- Technical information in which the working pressure is coded. The SDR class is indicated here, which can be deciphered from the table below.

- Service class and working pressure. Classes of operation of polypropylene pipes are coded with a number (see the table). Indicated for domestic pipes. They reflect the scope.

- The standard according to which the products are manufactured.

So the complete information is printed, which is necessary in order to determine where to use and under what conditions.

| Designation of the class of operation of PP pipes | Temperature of the transported medium (operating / maximum) in ° C | Area of use |

|---|---|---|

| XB | up to 20 | For cold water supply only. |

| 1 | 60/80 | For DHW with an operating temperature of 60 ° C. |

| 2 | 70/80 | For DHW with an operating temperature of 70 ° C. |

| 3 | 40/60 | For underfloor heating with a heating medium temperature up to 40 ° C. |

| 4 | 60/70 | Heating and underfloor heating systems with an operating temperature not exceeding 60 ° C. |

| 5 | 80/90 | Heating and underfloor heating systems with an operating temperature not exceeding 800 ° C. |

Additionally, we recommend reading the article "How to choose the best polypropylene pipes".

Diameters of polypropylene pipes: assortment according to GOST R 52134-2003

This GOST describes an assortment for pipes made of any type of plastic, one of which is polypropylene and its copolymers (modifications). The table shows the dimensions of polypropylene pipes (diameter and wall thickness), depending on what working pressure the pipe is designed for.

Standard diameters of polypropylene pipes and wall thickness depending on the maximum pressure in the pipeline

| Nominal outer diameter, mm | up to 25 atm | up to 25 atm | up to 20 atm | up to 12 atm | up to 7 atm | up to 5 atm | up to 4 atm | up to 4 atm |

|---|---|---|---|---|---|---|---|---|

| 10 | 2,0 | - | - | - | ||||

| 12 | 2,4 | 2,0 | 1,8 | 1,8 | ||||

| 16 | 3,3 | 2,7 | 2,2 | 1,8 | ||||

| 20 | 4,1 | 3,4 | 2,8 | 1,9 | ||||

| 25 | 5,1 | 4,2 | 3,5 | 2,3 | ||||

| 32 | 6,5 | 5,4 | 4,4 | 2,9 | 1,8 | |||

| 40 | 8,1 | 6,7 | 5,5 | 3,7 | 2,3 | 1,8 | ||

| 50 | 10,1 | 8,3 | 6,9 | 4,6 | 2,9 | 2,0 | 1,8 | |

| 63 | 12,7 | 10,5 | 8,6 | 5,8 | 3,6 | 2,5 | 2,0 | 1,8 |

| 75 | 15,1 | 12,5 | 10,3 | 6,8 | 4,3 | 2,9 | 2,3 | 1,9 |

| 90 | 18,1 | 15,0 | 12,3 | 8,2 | 5,1 | 3,5 | 2,8 | 2,2 |

| 110 | 22,1 | 18,3 | 15,1 | 10,0 | 6,3 | 4,2 | 3,4 | 2,7 |

| 125 | 25,1 | 20,8 | 17,1 | 11,4 | 7,1 | 4,8 | 3,9 | 3,1 |

| 140 | 28,1 | 23,3 | 19,2 | 12,7 | 8,0 | 5,4 | 4,3 | 3,5 |

| 160 | 32,1 | 26,6 | 21,9 | 14,6 | 9,1 | 6,2 | 4,9 | 4,0 |

| 180 | 36,1 | 29,9 | 24,6 | 16,4 | 10,2 | 6,9 | 5,5 | 4,4 |

| 200 | 33,2 | 27,4 | 18,2 | 11,4 | 7,7 | 6,2 | 4,9 | |

| 225 | 3,4 | 30,8 | 20,5 | 12,8 | 8,6 | 6,9 | 5,5 | |

| 250 | 34,2 | 22,7 | 14,2 | 9,6 | 7,7 | 6,2 | ||

| 280 | 38,3 | 25,4 | 15,9 | 10,7 | 8,6 | 6,9 | ||

| 315 | 28,6 | 17,9 | 12,1 | 9,7 | 7,7 | |||

| 355 | 32,2 | 20,1 | 13,6 | 10,9 | 8,7 | |||

| 400 | 36,3 | 22,7 | 15,3 | 12,3 | 9,8 | |||

| 450 | 40,9 | 25,5 | 17,2 | 13,8 | 11,0 | |||

| 500 | 28,4 | 19,1 | 15,3 | 12,3 | ||||

| 560 | 31,7 | 21,4 | 17,2 | 13,7 | ||||

| 630 | 35,7 | 24,1 | 19,3 | 15,4 | ||||

| 710 | 40,2 | 27,2 | 21,8 | 17,4 | ||||

| 800 | 45,3 | 30,6 | 24,5 | 19,6 | ||||

| 900 | 51,0 | 34,4 | 27,6 | 22,0 | ||||

| 1000 | 38,2 | 30,6 | 24,5 | |||||

| 1200 | 45,9 | 36,7 | 29,4 | |||||

| 1400 | 53,5 | 42,9 | 34,3 | |||||

| 1600 | 61,2 | 49,0 | 39,2 |

How long are PP pipes? If they are sold in sections, then the maximum length of a section is 24 meters. There may be less, the multiplicity step is 25 cm. Thinner ones - up to 180 mm in diameter can be in coils. Coil length - as agreed. There is only a limitation on the inner diameter of the coil: it must be at least 20 times the pipe cross section.

As you can see, the range is more than extensive. What are the diameters of polypropylene pipes usually used for home renovation? This, of course, is the "average temperature in the hospital", but in general the situation is as follows:

- For plumbing, the most common diameters are 16-25 mm. For risers, they are already taking thicker ones - from 30 mm to 110 mm. Risers are different.

- For heating systems, the wiring diameter is 32-40 mm, the piping for radiators is one step (one size) less. But it depends on the type of system. For gravity, both 90 and 110 mm may be required. Here you definitely need to count.

- Ventilation systems require large dimensions. Usually over 110 mm.

- PPR pipes for sewage usually differ in color, and in the presence of a bell and O-rings. You cannot confuse them. The smallest are 40 mm, but they are rarely used - to connect the drain from the sinks. Layers from the risers are made 110 mm or more.

All the given diameters of polypropylene pipes are approximate. So that you know at least which way to look. For each system, there are calculation or selection methods. It is better not to choose "by eye".

Connection method

As already mentioned, polypropylene is connected by welding. But despite the high level of plasticity, the minimum bend radius does not allow making turns even with an angle of 90 °, let alone steeper ones. All branches and turns are made using fittings. These are special elements for connecting plastic pipes. There is a whole range of different parts for each diameter.

The difference is that the marking indicates the diameter of the pipe for which these elements are intended. So you don't need any sizing. If you are using a pipe, say with a diameter of 25 mm, then simply take fittings with the same markings. It is better to buy both of the same company. Then there will be no problems. If you had to take products from different companies, to be sure, "try on" them. Take a piece of pipe to a store and check compatibility. It should enter without any problems, but tightly, without gaps.

16 mm cannot be found in Russia

aluminum is reinforced not only to compensate for thermal expansion, it also creates an oxygen-tight barrier

there are pipes PN 22 - heat-stabilized PP - PPRCT