Sandwich panels: what it is, types, methods of connection, installation, properties, tables of sizes and weights

Not everyone has the desire and ability to delay construction for several years. Moreover, there is no need for a long time. There are several technologies for fast construction. The leaders are skeletons. We get a full-fledged building very quickly at a minimum cost. But the frame is only half the battle. We still need to choose the trim. One option is multi-layer materials. They are called sandwich panels. The dimensions of the sandwich panels make it possible to further reduce the construction time, because we immediately get a building with an exterior, and sometimes with an interior decoration.

The content of the article

What is sandwich panel

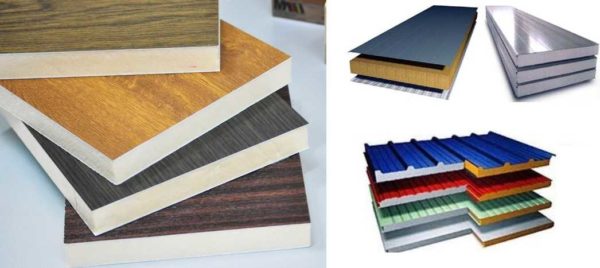

Sandwich panels are a modular building material designed for cladding buildings and structures that are built using frame technology. They consist of three layers: two sheets of rigid material and insulation between them. The use of this material significantly speeds up the finishing and construction of buildings, since the outer cladding, insulation, and inner cladding are immediately mounted. And also, the dimensions of the sandwich panels allow covering the roof of a rather large house without horizontal seams - the maximum length of a sandwich panel can be 12 meters. More than enough for gable roof... The only question is transportation, but that's another story.

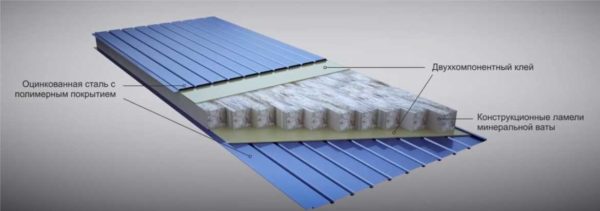

So, the structure is three-layer. The layers are glued together and pressed at the same time. There are two pressing methods - cold and hot. In any case, the layers are held securely. It is impossible to tear apart from each other without the use of mechanisms.

A sandwich panel is a building material for cladding frames. Consists of two sheets of rigid material, between which there is a layer of insulation

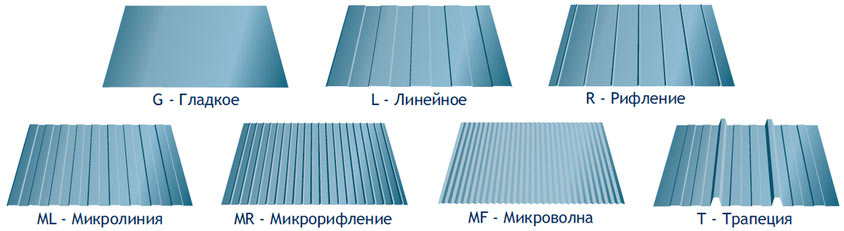

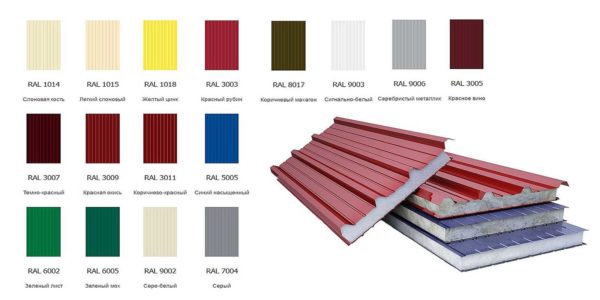

There are wall and roof sandwich panels for their intended purpose. They usually differ in appearance, in the thickness of the materials used and in the type of profile. There are smooth slabs, there are different types of profiles. There are roofing ones with corrugation like a profiled sheet, and there are very similar to metal tiles.

There are also special-purpose options. For example, for garage doors. These are usually steel sheets, but coated with pural or some other damage-resistant polymer. They differ in the shape of the castle. Such gates are usually made lifting, so that the locks have a different shape. And the longitudinal edges are not open, but closed with the same steel sheet, which is bent, forming a smooth bevel.

Wall sandwich panels can be smooth or corrugated. It is traditional (wave, trapezoid, shallow corrugation), and there is more decorative - like stone, brickwork and even wood.

In general, the appearance of sandwich panels can vary.

What are they made of

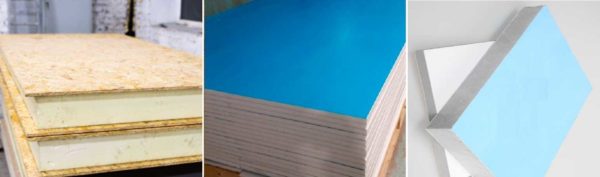

The materials of the outer layers of sandwich panels can be different. The most common with a "shell" made of sheet steel, but there are also aluzinc, drywall, plastisol, polyester, pural, DSP, OSB (OSB), chipboard. The choice of material depends on the purpose of the building that is going to be finished and on the place of installation. The dimensions of sandwich panels do not depend on the materials of the layers, so there are no restrictions.

For example, in the construction of storage and production, utility rooms, both sides are steel sheets.The coating and profile of the inner and outer sheets can be different for the required tasks. When sheathing the outer walls of private houses, there may be metal outside, and inside GVL, gypsum board, chipboard, OSB. It depends on what the owner has chosen. For partitions, there are options on both sides with fiberboard, gypsum board, OSB and chipboard or their combinations. The material is good because there are different options both in terms of characteristics, and in appearance and in price.

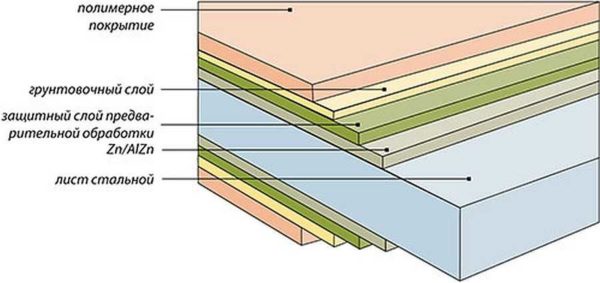

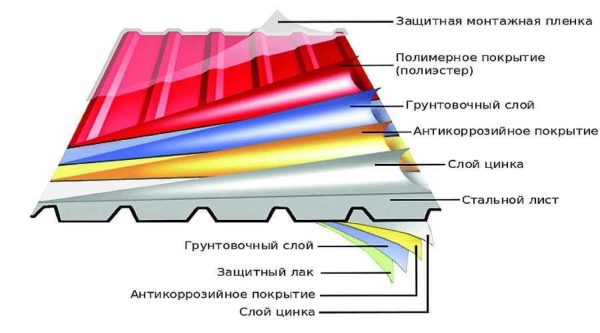

Outer layer - steel sheets

Sheet metal is used as the outer layer of sandwich panels. Sheet thickness - 0.35-0.7 mm. If the metal is placed on both sides, then for the outer one they take a thicker one - 0.7 mm, for the inner one - thinner - 0.35-0.5 mm. Agree, this is justified. Firstly, the weight is less, and secondly, the cost is lower. And the strength for the inner lining is more than sufficient. Even if it is a production facility.

The metal is covered with several protective shells. Necessarily galvanized, and then additional layers are applied - primers and polymer coatings, which protect and give a more "civil" look.

Types of polymer coatings for sandwich panels

Steel quality is very important, but galvanizing and the quality of protective coatings are equally important. The durability of the metal depends on how carefully the coating is applied, and therefore the reliability and durability of the wall or roof. First, the steel sheet is coated with zinc, and then one of the types of polymers is already applied to the galvanized surface. This could be:

- Polyester - SP or PE. Inexpensive, resistant to ultraviolet light, corrosion, temperature extremes, does not fade for a long time. It is applied with a thickness of 25 microns. The disadvantage is low resistance to mechanical damage. You can even scratch it with a nail.

- Polyvinylidene fluoride (PVDF, PVDF). Very high resistance to fading and high temperatures, chemically aggressive environments. Coating thickness 20-25 microns.

- Polyurethane. It is applied with a layer of 35-55 microns. Requires a good primer. Does not fade, tolerates temperature changes. Good for roofing materials.

- Polyvinyl chloride (PVC or PVC). It is applied in the thickest layer - up to 200 microns. Has the highest resistance to mechanical stress. It makes sense to use for wall panels. But it does not tolerate high temperatures. Maximum long-term heating is not higher than 60 ° C. Best used in the Midland and North.

- FARM. Well tolerates chemical environments, resistant to corrosion, ammonia and fertilizers. It is used in poultry houses and houses for livestock, granaries. It can only be applied on galvanized surfaces, with a zinc layer of at least 275 g / m².

- Sanitary coating CLEAN (Food Safe). It is safe for food contact. Does not react to salt, acid, alkali and solvents. This coating is used in buildings related to the food industry, medicine, pharmaceuticals, electronics.

Of all this list, polyester, PVC and polyurethane are most often used. Sandwich panels are also made of stainless steel sheet. Such sandwich panels are used in refrigeration chambers in food or pharmaceutical companies.

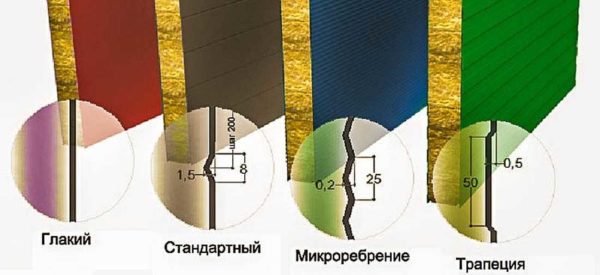

Sandwich Panel Profiles

Sandwich panels with external metal cladding can be smooth and profiled. Smooth ones have lower mechanical resistance; it is easier to make dents on a flat surface than on a grooved one. If the house is in the yard, the probability of damage is low. Moreover, the paths can be made not close to the walls of the house, but make a soft blind area and over plant a flower garden or sow the lawn.

You can also take profiled sandwich panels for frame cladding.Some look exactly like clapboard, but there are more interesting options. True, and for the price they are "more interesting".

Insulation

Insulation for sandwich panels is also used in different ways:

- mineral wool (stone or glass);

- polyurethane foam (foam or PPS);

- expanded polystyrene (PPU or PUR);

- polyisocyanurate foam (PIR).

Best of all - the last - PIR. It appeared quite recently. It has thermal technical characteristics on a par with polyurethane foam, but better in terms of fire safety (it tolerates heating up to 140 ° C without destruction and ignition). Its disadvantage is the high price. In general, they usually choose between mineral wool and polyurethane foam. Polyfoam loses to both of them, although it costs less. But the difference in price does not cover the difference in performance.

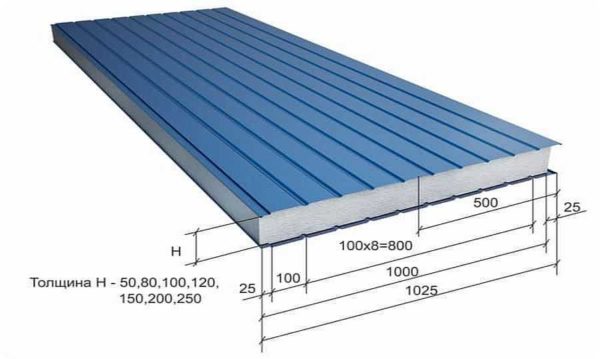

Sizes of sandwich panels

There are no standards for this type of building material, therefore, if you wish, you can find or order those sizes of sandwich panels that suit you best. Many manufacturers go for it. It is not a fact that a large enterprise will make a small batch for your requests, but you can agree with small ones. Although, you can talk to the big ones.

Most likely, "custom" sizes of sandwich panels will be more expensive (in terms of square meter). But this can be justified. Less cuts / waste, less cost in the end. In general, you need to count and watch. In general, each enterprise has its own maximum and minimum dimensions. They depend on the available equipment. The table summarizes the most common sizes of sandwich panels. They were divided according to their purpose - wall and roof. Since they are usually different.

| Length | Useful or working width | Thickness | |

|---|---|---|---|

| Wall | from 2000 mm up to 12,000-14,000 mm | 1000 mm 1150 mm 1190 mm | from 30 mm to 250 mm |

| Roofing | from 2000 mm to 16000 mm | 1000 mm 1150 mm | from 50 mm to 220 mm |

Note whether the "working" or "useful" width is indicated. In fact, the size of each panel will be slightly larger - just due to the lock. When calculating the quantity, you will need exactly the working width. And the actual one will be required for transportation, but it is rarely indicated by anyone. You can check with the sellers. And on average, you can throw on 15 cm. This is more than enough.

One more point. Not all manufacturers have all the sizes of sandwich panels indicated in the table. These are "combined" results. The most common values are selected. But one company offers only one width, another - two or all three options. Likewise, not everyone can make a 12-meter sheet. Someone has a maximum of 6.3 meters. So again, monitor the situation in your region.

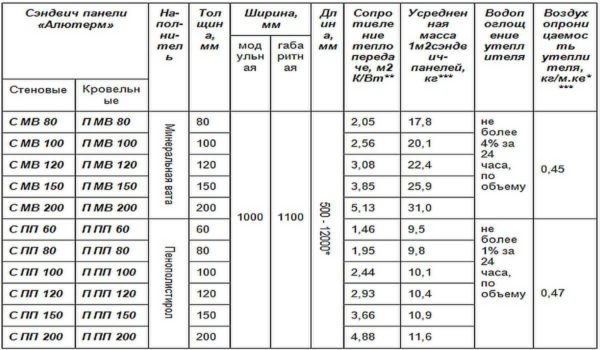

Specifications

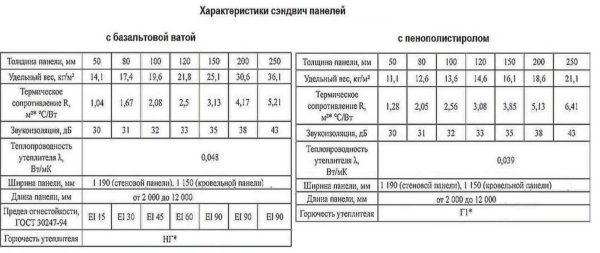

As you can imagine, it is difficult to talk about the characteristics of sandwich panels "in general". Materials that are too different can be used. And "sheathing", and insulation, and the thickness of all layers. These are all different. And the characteristics of each of the components vary over a wide range. Therefore, the specific properties should be looked at when the manufacturer has been decided. In the meantime, so that you can navigate, we present the data of one of them. By the way, you can see the tables in the paragraph about the types of insulation. This is data from one of the sites. In this section, we provide data from another manufacturer. At the same time, you can evaluate the run-up of values.

If you compare the two tables, you will see that in the first case, a sandwich with expanded polystyrene has a higher thermal resistance. In the second, on the contrary, basalt wool turned out to be warmer. And no one is lying. They just use different materials. That's all.

The bearing capacity may also be interesting. Here the situation is about the same as with thermal resistance. Depends on the metal, the presence or absence of relief, its shape and size.Also, the insulation and the method of connecting the layers make their contribution. In general, there are also a lot of criteria. So, the meanings must be learned from a specific material. And we give the table for reference only, so that you can roughly estimate the possible load.

As you can see, quite a decent bearing capacity. This makes it possible to make not only walls and roofs from sandwich panels, but also ceilings. Not a bad way to speed up construction.

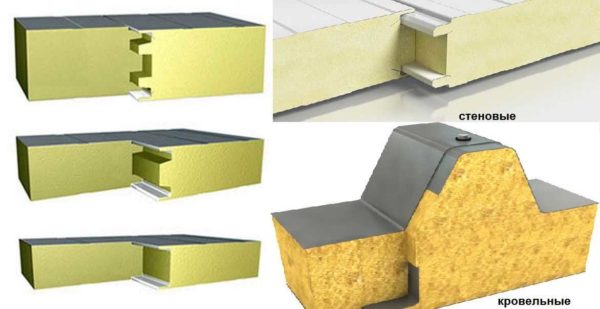

Connection of sandwich panels to each other

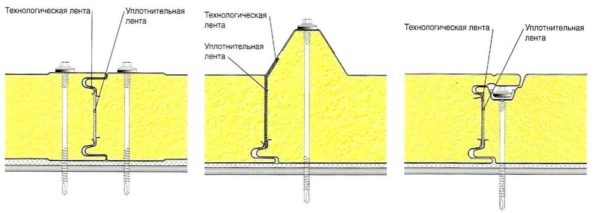

Sandwich panels are interconnected with locks. Wall and roof locks differ significantly. On one side of the rooftops, the release of steel in the form of a wave is specially made. It is "put on" on the protrusion of the previous sheet. This is how the connection takes place. In the wall panels, the lock is made according to the thorn-groove principle. Moreover, it is better if, according to this principle, not only the outer skin is connected, but also the insulation.

In general, in the entire structure, it is the joints of the panels that are the weakest points. Not only in terms of safety, but also in terms of keeping warm. The first panels were connected only with metal sheets, and the heaters were simply joined. But the seams froze, so they began to complicate the shape, creating labyrinths. Also, when connecting, additional sealing tapes are used in order to precisely avoid blowing and freezing.

Wall panels for vertical installation must be fixed. This is not necessary for horizontal. It is also mandatory to install fasteners when laying sandwiches on the roof.

In some cases, additional fixation is used - self-tapping screws or pins. Some forms of locks allow the fasteners to be hidden, in others it is installed from above. By the type of installation of profiled sheet and metal tiles.