Silicate brick: pros and cons, sizes, application features

A brick house is considered one of the most reliable. Houses are built from ceramic and silicate bricks. Both of these materials have adherents and opponents. What is good about sand-lime brick, what flaws it has, what types there are, standard sizes - all this is in the article.

The content of the article

Composition and production method

In the GOST 379-2015 standard, silicate bricks and blocks are defined as products from a mixture of siliceous materials and lime or components containing lime. Color pigments and lightweight fillers are also allowed. The production method is pressing. So most of the silicate brick is sand (about 90%), the rest is lime and pigments. Aggregate is rarely used to reduce the weight of the finishing material. The moistened mixture is compressed, then steamed in a pressure autoclave.

The bricks formed in the press are sent to an autoclave, where they are processed with steam at high pressure.

As you can see, there is nothing harmful in this material. Some are alarmed by lime, some of which may remain free. After all, silicate brick is only processed with steam (at a pressure of 10-12 atmospheres and a temperature of about 200 ° C). In theory, some of the lime can remain unreacted (not extinguished).

In general, this is certainly possible. But the unslaked lime will react with water, which can be absorbed into the sand-lime brick. In this case, it will be extinguished. If the material freezes during the reaction, we will observe the so-called "shooting". When, after freezing, part of the wall falls off, as if cut off. If we see such a phenomenon, it means that the technology was violated. Because many houses made of high-quality silicate stand for decades, withstand more than one winter and spring without visible changes. In general, high-quality sand-lime bricks can be used for both exterior and interior walls. This is exactly what the GOST says.

Pros and cons of silicate bricks

Let's start with the biggest pros. Sand-lime brick has very good geometry, high dimensional accuracy. This makes it much easier masonry... Second point: good quality material looks very decent. The most common color is white. Even if you use it, and take a dark solution, it looks good. The addition of pigments and fillers allows for a wide range of colors. There are also types with a decorative surface.

A significant plus is high strength and low price. Good sand-lime ordinary brick is about 50-60% cheaper than similarwow ceramic... If we compare silicate and clinker finishing, the difference will be even more significant. In general, a worthy option both for the construction of walls and partitions, and for decoration.

disadvantages

Let's look at the disadvantages that sand-lime brick has:

- High water absorption. GOSTs for silicate and ceramic bricks determine only the lower limit of water absorption. Moreover, it is the same: the absorption of moisture by silicate and ceramics must be at least 6%. There is no upper limit. In fact, for silicate products, this indicator is in the range of 8-16%. For ceramics, the situation is at least no better.In fact, 10-18% is not that much. Moreover, silicate tolerates wetting without much damage, and it absorbs and releases moisture equally easily. Otherwise, all garages, which are mostly built from this material, would have a very deplorable appearance. And they look very good, although in garages made of silicate bricks, the material is used in very harsh conditions.

- Heavy. If we talk about a solid silicate brick, then the standard one has a weight of about 4 kg ± 300 g (depending on density). Compared with ceramics of the same dimensions, this is 3.4-3.8 kg. A little less, but not critical.

- Worse plastering. This is objective, but you can fight it. First, you need to choose the right plaster, taking into account the fact that it will be covered with silicate, which contains, albeit slaked, but lime. Second, smooth walls really “hold” the plaster worse. This is leveled by the use of plaster mesh.

In general, no ideal building material has been invented. All have their drawbacks and silicate is no exception. But he's not that bad. The best part is that the technology is simple. If you stick to it, the quality is guaranteed. A good sand-lime brick does not lose strength over time. Look at houses built decades ago - they don't have efflorescence. Yes, the walls have turned gray, but they do not crumble or collapse. Yes, it is "not too warm", but according to modern standards, ceramic bricks also require insulation. So this is also not an argument. In general, the situation is ambiguous. As always, it is important to choose quality material, and this is perhaps the most difficult thing.

Types and sizes of silicate bricks according to the state standard

The dimensions and properties of sand-lime bricks and stones are described in two standards. GOST 379-95 and GOST 379-2015. The latter contains additional information on silicate blocks, colorants and light fillers that have come into use in recent years. According to the standard, there are the following sizes of sand-lime bricks:

- Single. Has dimensions 250 * 120 * 65 mm. In the marking is indicated by the letter "O".

- Thickened or one and a half. Differs in greater thickness, has dimensions 250 * 120 * 88 mm. It is marked with the letter "U".

- Sand lime brick EURO. Has dimensions 250 * 85 * 65 mm or 250 * 60 * 60 mm. This is a finishing material, ordinary ones are not produced in this format. In the marking, they usually write EURO SL and further parameters.

- Silicate stone. It is twice as thick as single. That is, it has dimensions of 250 * 120 * 138 mm. Double silicate brick is often called, but this is not a GOST name.

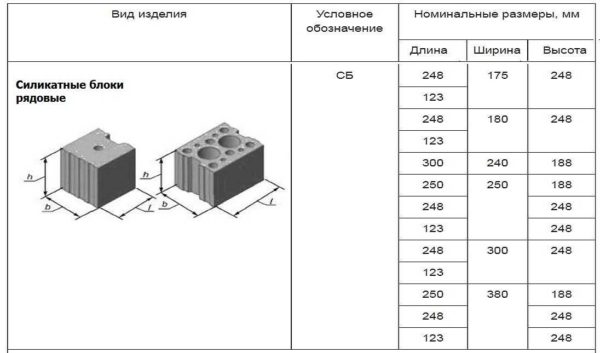

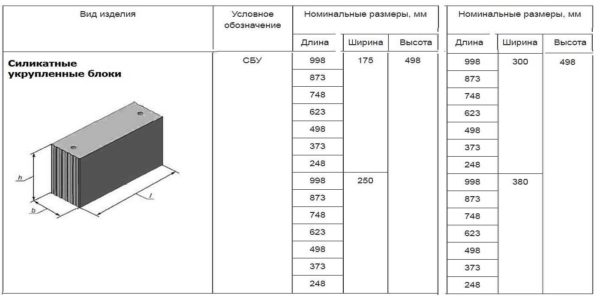

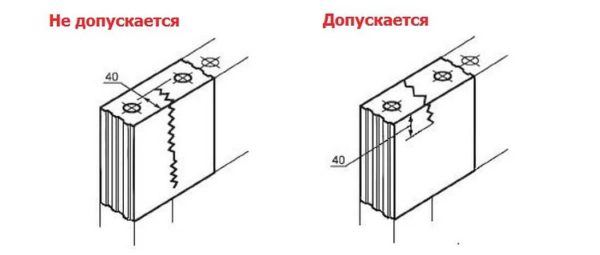

- Silicate block (in the designation SB) and enlarged silicate block (designated by SBU). A product with a poke width of more than 130 mm. The sizes of silicate blocks are given in the tables. They are used for the construction of partitions, there are no finishing blocks. Their end parts (butts) may have formed tongue-and-groove edges. This makes it possible to increase the thermal insulation characteristics of the masonry, since a direct freezing seam is excluded.

That is, according to the standard, the width and length of the silicate brick are the same. The width is 120 mm and the length is 250 mm. Only the thickness changes. Moreover, a deviation from the nominal dimensions is allowed only within ± 2 mm.

Varieties: finishing and masonry

Silicate bricks and stones can be facing and ordinary. Private - ordinary, for laying walls and partitions. In the marking it is indicated by the letter "P". Facing silicate brick (marked with the letter "L") has one or more smooth or decorative sides. It can also be called finishing or decorative. There are these types of facial stone:

- Smooth surface:

- White.

- Dyed in mass (volume dyed). The pigment is added to the mass before molding. On chips it has the same color as on the surface. The marking contains the letters "About".

- Coated with paint, glaze or polymers.

- Textured or decorative with a raised side. It is indicated in the marking with the letter "D". It can have only a front decorative surface, or front and butt.

- Chipped. With a "torn" surface on the spoon, which is formed when the stone is cracked. It is designated by the letter "K".

- Rusty. With a surface "like a natural stone". The marking is designated "Ru".

One or two faces of any type of facing brick can be coated with a hydrophobic composition. This impregnation reduces water absorption, extends service life and improves the appearance of the material. The letter "G" is added to the marking. Another finishing sand-lime brick can be with rounded edges or chamfered.

Corpulent and hollow

There are two types of sand-lime bricks: with voids and without them. Solid brick in the marking is designated as "Po", hollow - "Pu". The number, size and location of voids is determined by the manufacturer. Voids may or may not pass through. There are two requirements for them:

- located should be perpendicular to the brick bed;

- the thickness of the outer walls must be at least 10 mm.

The shape, size, location of voids are not standardized. The outer wall must be at least 10 mm. These are all requirements

Neither the shape nor the location of voids on the surface are standardized. Therefore, the weight of the hollow brick may differ at each plant. Moreover, the marking and all other indicators will be the same.

Specifications

The main characteristics of building materials for the construction of walls are strength, thermal conductivity and water permeability. In terms of strength, silicate brick can be of seven grades: M100, M125, M150, M175, M200, M250, M300. By this designation, you can determine what load a brick can bear. The figure indicates the number of kilograms of load per square centimeter.

For example, silicate brick with strength grade M125 - can withstand a load of 125 kg / cm², M200 - 200 kg / cm². In fact, it is not easy to find a silicate brick or block with the M200 brand. And all the rest exist, for the most part, only theoretically. If they are, then the price is such that no one will buy them.

According to GOST, silicate brick must have a water absorption of at least 6%. The upper limit is not defined, and the accompanying documents indicate the result that was obtained during laboratory tests of the batch at the plant.

The standard also defines frost resistance grades: F25, F35, F50, F75, F100. This characteristic shows how many defrost / freeze cycles the material takes out. If silicate brick is used for internal partitions, frost resistance does not matter, but for finishing or for laying walls, this parameter is very important.

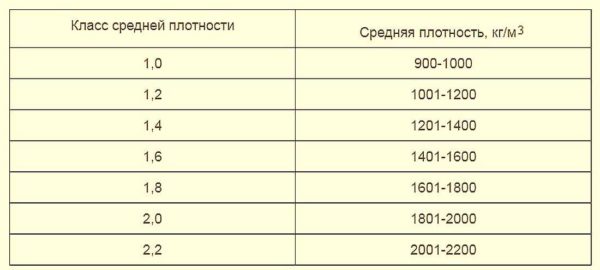

Another characteristic spelled out in the standard is density. The marking indicates the class of average density. If you look at the table, you can see that the maximum boundary just coincides with the class number. This can be used when decrypting. The standard deviation is allowed for each class of 50 kg / m³, but no more.

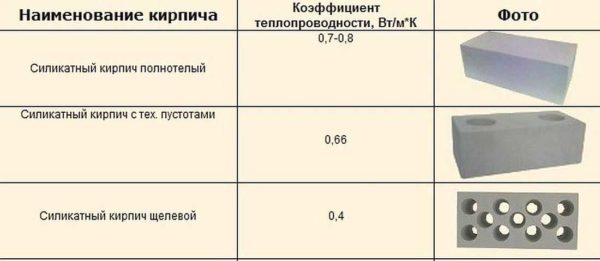

Thermal conductivity and sound insulation characteristics depend on the density and number / size of voids

The accompanying documents for the batch must also indicate the thermal conductivity and sound insulation characteristics. These characteristics of silicate bricks are not standardized and must be indicated based on the test results of each batch.

Marking and its decoding

In the marking of silicate bricks, the name of the material is first indicated. For silicate, this is the letter "C". Next comes the standard size - "O" - single, "U" - thickened (one and a half). Then the type is ordinary (P) or front (L), then there are designations for the presence of voids (Full-bodied and Hollow Pu) and the type of front surface. Let's look at some examples with decryption.

- SORPo-M200 / F75 / 1.8 stands for as follows: C - silicate brick; О - single (dimensions 250 * 120 * 65 mm); Po - corpulent; brand M200, frost resistance 75 cycles, average density 1800 kg / m³.

- SULPu-M100 / F50 / 1.6 we read as: C - silicate brick, U - thickened (dimensions 250 * 120 * 88 mm); L - front, Pu - hollow; strength M100, freeze-thaw cycles 50; average density 1600 kg / m³.

- SULPuRuG-M100 / F50 / 1.4 -C - silicate, U - thickened (one and a half with dimensions 250 * 120 * 88 mm); L - front (facing); Pu - hollow, Ru - rusticated; D - with hydrophobic treatment. Strength class M100, frost resistance 50 cycles, density class 1.4, specific gravity - about 1400 kg / ³.

Double brick - there is no such thing in the standard. What we usually call that is referred to as a silicate block. Before the marking is the letter "B" which means the word "block", and then all the same numbers and letters with the same meanings. With the exception that the block is only ordinary - it is not produced as a finishing material. For example, block SBUO-M200 / F150 / 2.2. It stands for silicate block, U - enlarged, Po - corpulent. The rest of the parameters are clear.

In general, the marking contains all the necessary data. The exception is weight. But it depends on the density, presence and size of voids. So this parameter should be looked at specifically for each plant, and for each position.

Appearance requirements

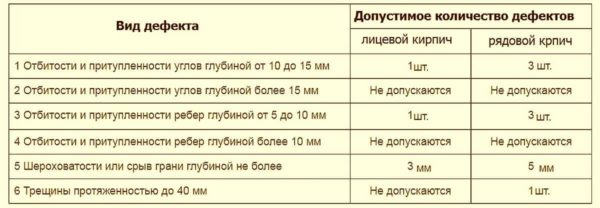

The standard also prescribes the requirements for the appearance of facing and ordinary silicate bricks. Facing brick, colored in the mass, must comply with the standard. Small - up to 5 mm - inclusions of unpainted mass are allowed. Other possible disadvantages are summarized in the table. Basically, there may be a chipped edge and fuzzy edges. The sizes of chips and their number are standardized.

Allowed by the standard some roughness or disruption of the edge, in an ordinary brick there may be small cracks - up to 4 cm long. Cracks may not be any. A crack of any size that extends over the entire spoon or most of it is unacceptable. It is acceptable if a brick is cracked across the width of the bed. But the crack size cannot be longer than 40 mm.

In ordinary silicate brick of any size and type, inclusions of clay, lime, sand or any other foreign inclusions are unacceptable. They should not be on the surface or on a fracture, if there are half or damaged elements. At the same time, such inclusions can be present on the "rough" sides of the facing silicate. But the size of inclusions is no more than 5 mm and they should not be more than 3 pieces per brick / block.