Strip foundation: types and features

The most popular foundation in private construction is strip. This is one of the most flexible foundations that can be designed for any building and for any soil. It is laid along the perimeter of the building and under all load-bearing partitions, which is why it looks like a tape. In cross-section, it most often looks like a rectangular parallelepiped, sometimes with a wider base, sometimes without. The width of the tape should be the same everywhere. The depth of the laying is determined based on the selected type of foundation, climatic factors, the type and mass of the building, the geological structure on the site and the level of groundwater. All these factors together determine the parameters of the foundation strip.

You should not do it on unstable and water-saturated, highly heaving soils with a large freezing depth (more than 2 meters). It can be designed, but it will cost a lot. They are also not suitable for peatlands or loess soils. Usually other types of foundations are optimal in such conditions. Also, tapes are not always used for light structures - frame or wooden: for them there is a cheaper, but no less reliable type - columnar or pile (pile-grillage). In all other cases, it is the strip foundation - most often - the best option.

It is used not only in the construction of houses. It is made during the construction of a fence, garage, capital outbuildings.

The strip foundation is very plastic - it can be made for any building and construction, giving any shape

Project: to order or not

Building a house requires a lot of money. Naturally, there is a desire to save money. But the foundation is not the stage at which it is worth saving, because its incorrect construction will lead to problems, the elimination of which will require much more money. Therefore, it is desirable to order a project, as well as a geological survey.

This stage can be dispensed with only when building small houses, baths, temporary or outbuildings. If a capital house is being built, moreover, from heavy materials, then the risks are too great. But it's up to you.

Actually, there is enough information for the independent design of foundations, especially belt foundations. But the lack of knowledge and experience often leads to two opposite results:

- The foundation was made with an excessive margin of safety for the given conditions. This is good from an operational standpoint, but leads to increased costs, often exceeding the design cost.

- Insufficient safety factor or improper design resulting in uneven soil settlement. The result is cracks in the walls of the house.

As you can see, both options lead to cost overruns: during the construction phase or for refurbishment and repair. And it's not a fact that design work will cost more. Rather, the opposite is true. The calculation of the foundation can cost about $ 100-250, but it requires geological data on the site, and these studies cost around $ 1000. For a small building, you can conduct research on your own, but for a solid one it is better, probably, to trust the professionals.

Types of strip foundations and their use

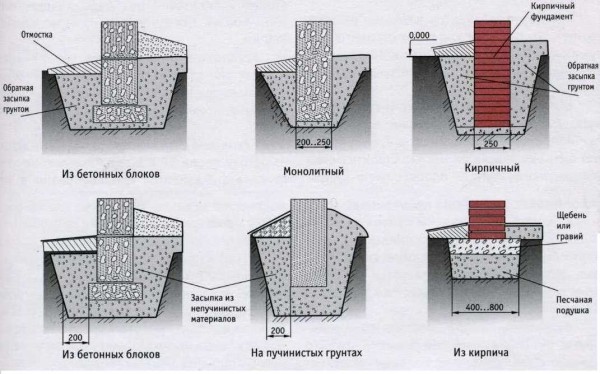

During the construction of a strip foundation, several types of materials can be used, the name changes accordingly, there are differences in technology. What remains unchanged: digging a foundation pit and preparing the base. The rest of the steps are subject to change. Briefly, types can be described as follows:

- When using concrete mortar and reinforcement, the strip foundation is called monolithic. All work takes place at the construction site.First, a formwork is installed in the dug pit - a prefabricated structure that gives shape to the concrete solution. Then the reinforcement is laid and tied, then poured with concrete. Subject to technology, the service life monolithic strip foundation about 100-150 years. Therefore, it makes sense to use them for structures made of materials, the service life of which is comparable to the named interval. It takes a lot of time for all the work: assembling the formwork, tying reinforcement, pouring and processing the mortar. It all takes weeks.

If concrete is poured directly on the construction site, we get a monolithic foundation

- Precast concrete strip foundation. It consists of reinforced concrete blocks cast at the plant. They are of two types. Trapezoidal (also called a pillow) are laid down, wall foundation blocks (FBS) are installed on them in one or several rows. They are connected to each other by reinforcement, the gaps are filled with mortar. Life time foundation made of FBS - about 50-70 years, which is comparable to the service life of frame houses. The work with this option is much less (several days), but in most cases it is required to rent lifting equipment - winches for small buildings or a crane for more serious projects. It should be remembered that the strength of a prefabricated foundation is 20-30% lower than that of a monolithic one, which is why they are not used on heaving or subsiding soils.

To speed up construction, at a low groundwater level, the tape is assembled from ready-made concrete blocks

- Rubble strip foundation. It is built from natural rubble stone. Sometimes with concrete, sometimes without. When using concrete, one speaks of a buto-concrete foundation. Erection requires a lot of experience and high qualifications of workers: the stones must be laid correctly, because they are bound only with mortar. Such foundations can be used on stable non-powdery foundations, otherwise there is a high probability of cracking or complete destruction. Service life - as for prefabricated 50-70 years.

Rubble foundations require high skill: the stone must be laid so that the house does not spoil later.

- Brick strip foundation. This is a private version of the prefabricated foundation. In this case, most often, first, a monolithic tape with an armored belt is poured along the perimeter of the foundation, and a brick wall is folded on top. Sometimes building blocks are used instead of bricks. It is worth sitting down that both brick and building blocks are hygroscopic and do not have the longest service life. In terms of reliability, these are the most problematic and low-living foundations: their service life is 30-50 years, and this is with proper design and implementation.

Brick foundation is not very popular today: high labor intensity and short service life are the main reasons

The most common is a monolithic strip foundation. Although it has the greatest labor intensity, it is a single structure that is capable of redistributing loads. Therefore, it is often used on heaving soils. If the soils are dry and sound, a precast concrete foundation can be installed. It often has a high cost, but it takes less time to erect, which is sometimes also important.

Rubble and rubble concrete foundations are used mainly in regions with a sufficient amount of suitable material - in mountainous or close to them. There, firstly, the grounds for them are ideal, and secondly, there are also good specialists who are able to competently perform the work. In lowland areas, the delivery of stone is unprofitable, and even a master cannot be found.

Brick foundations have rarely been made recently. Despite the general availability of the material, it has far from the best characteristics and requires significant costs for the organization of waterproofing, as well as insulation. As a result, its cost increases significantly.With a short service life, this is completely unprofitable even on stable soils.