DIY arch: step by step instructions (drywall), 3 ways

One way to increase living space is to remove doors. But there is not always the ability or desire to destroy the walls. Then the former doorway is made in the form of an arch. Another option for using arched openings is to divide a long corridor into zones, breaking up too simple geometry. When repairing on their own, they most often make drywall arches: it is easiest to make them with your own hands.

The content of the article

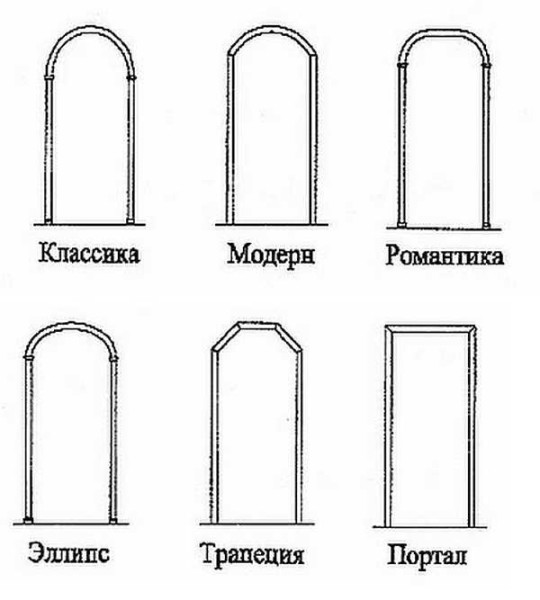

Types of arches

Interior or corridor arches can have different shapes. They differ mainly in the shape of the upper part and sometimes in the way of connection with the vertical parts. Their main types are shown in the photo.

This group lacks one of the most popular in recent years - the semi-arch. They have a rounded corner on one side only, on the other it remains straight. Hence the name - semi-arc. It looks good in modern interiors: minimalism, hi-tech, maybe in art deco.

The classic is distinguished by the correct shape of the top. This is strictly a semicircle, the radius of which is half the width of the doorway. This view looks good with an opening height of at least 2.5 m. It fits well into any interior, but looks best in a long corridor, or instead of the front door to the kitchen.

The arched opening in the "Modern" style is distinguished by a small radius of curvature and a sharp transition at the junction with the vertical components of the opening. It looks good if the walls and ceiling have a more or less simple structure. Looks great on the site of the former balcony door, good when entering the office.

The arch of the "Romance" style is rather just rounded corners (basically, the masters call it that). Looks good at large widths and not the greatest height.

The "ellipse" shape is very close to "romance". Differs only in greater curvature in the middle. Also suitable for low and wide openings. It only looks a little softer.

Trapezium is a non-standard design consisting of broken lines. It is played hard in the interior, therefore it is rarely used: for some non-standard designs.

It is very similar to an ordinary opening, but in fact it is, only without a door leaf. For more originality, it is often accompanied by wooden carved elements in the form of columns on the sides. In this form, it is good for classic interiors, as well as ethno-style - Greek or Roman, depending on the type of columns.

For decoration in modern styles, they use another prim - next to the main arch, smaller portals are placed. This technique allows you to "beat" a simple form.

Before you start making an arch, you need to decide on its parameters. select a type and then options: where it will start from, and what radius of curvature it will be. It could be a really steep bend, or it could be just some rounding of the corners.

Rounded corners in standard doorways look better than steep arched curves

To get an idea of how your chosen shape will look, you can cut a template out of cardboard and attach it to the doorway. Assess the effect. If everything suits you, you can make a blank using this template. But only one - for one side of the opening. The second must be done in place, otherwise it will turn out crooked.

Step-by-step instructions with a photo: the fastest way

Do-it-yourself drywall arches are made in different ways. This takes a minimum amount of time. Having decided on the form, we proceed to the installation. On the prepared opening - cleaned of peeling plaster and relatively leveled, we attach the frame to the size of the future arch. It is made from a drywall profile or dry wooden block of a suitable size. Sometimes, if the wall is narrow, only wood can be picked up.

The frame from the profile is screwed according to the selected dimensions

To begin with, we cut out a rectangle from the drywall according to the dimensions of the future arch, find its middle, mark it, and then temporarily fasten it in place. We retreat from the edge 12.5 mm - the thickness of the drywall sheet. If the adjacent walls are already plastered, add a couple more millimeters to the putty so that the surface can be leveled.

Screwed the drywall in place

Now we take a piece of a profile or a rigid corner, from one edge we set aside half the width of the opening. At this place in the corner we make a hole, insert a carnation into it. We stick this nail into the middle of the doorway on the sheet we marked earlier. It turns out a kind of compass, with which it is easy to draw a perfect line.

Arc delineator

By changing the height of the mount, you can get a more or less high arch. If you need a flatter curve, increase the length of the compass.

Using a corner, draw an arc

Having removed the sheet, we cut out the arc along the outlined contour. This can be done with a special drywall file, a metal saw with a fine tooth for a smoother edge, and a jigsaw (there will be a lot of dust). If the cut is not very smooth, we align it with sandpaper fixed to the grater. With this device, we achieve a perfectly flat curve of the shape we need. The cut out fragment of the arch - the side wall - is again fastened in place.

If everything is even, there are no distortions or irregularities, on the other side of the opening we attach the same drywall sheet as a few steps earlier - a rectangle or a square - depending on the shape. It must be fixed strictly vertically. Now we transfer the shape of the arch to it. We take a square, at a right angle and with one side we press against the drywall, onto which we transfer the arch, with the other side - against the arch. Putting the square perpendicularly, mark a point with a pencil. We make such points along the entire arc. The more often they are done, the easier it will be to draw a line and the more accurate the match will be - less grinding will be required.

Why is it so difficult and not just to make a copy of the first sheet? Because few openings are symmetrical. As a result, it is very problematic to install the second sheet so that the lines of the arch coincide.

Having marked all the points, remove the sheet, draw a line, cut it out along it. We mount in the same place. Now we again take the trowel with sandpaper and now level both edges until they match. One moment - the trowel should be wider than the opening so that both walls of the arch are captured in one pass.

We measure the length of the arc, cut out a piece of the profile of the same length, make notches on the walls every 3-4 cm. This tape will need to be fixed along the arch on one side and on the other.

We fix it on the screws, carefully, pressing the profile and holding it with a bar, and not with your fingers: getting into the fingers with a screw is elementary. By the way, you need to work with the cut profile with gloves. If not, you will cut your hands for sure.

By the way, the back of the profile can be positioned along the edge - it's easier to work this way, and then the joint will still have to be repaired. In the same way, screw the strip to the other side.

There is a second way to attach the profile - to plant it on a fast-setting universal glue, such as liquid nails. This method is acceptable if the opening width is small. With a large arch thickness, the glue may not withstand the mass of drywall, which will be attached from below.

The next step is to attach the jumpers. First, the depth of the arch is lost, 1-1.5 cm is subtracted from it. This will be the length of the jumpers. Pieces of a profile of this length are cut.

In the places where the jumpers are attached, "petals" are cut off, the prepared fragment is installed and fixed. It should not rest against the walls, it is located about 5 mm from the back. Jumpers are needed to make the structure more rigid, otherwise it "walks" when pressed.

Next, a rectangle must be cut out of drywall, which will cover the structure from below. Its width is determined simply - from the outer edge of one sheet of gypsum board, to the outer edge of the second sheet. The length is measured with a flexible tape (you can tailor it) or a tape measure with an assistant. We fasten this sheet with self-tapping screws to the arch frame. The sheet has to be bent, and read how to do this a little below - towards the end of the article.

Further, finishing work remained: a special corner is attached to the corner, everything is putty according to the usual technology: first, starting joints and corners, then finishing.

Arched plasterboard opening: the second method (photo report)

This method is good if the thickness of the partition is small: try attaching the profiles, if the gap between them is several centimeters, and then fasten the lintels. It all starts the same way: the first wall of the arch is cut out, attached and transferred to the second sheet.

After the width of the gap between the two sheets, wooden beams are cut out, which are attached along the edge of the arch with self-tapping screws.

The cut strip of drywall is fastened starting from one side. To make it more convenient, you can fix it with clamps, since the thickness of the wall is small. When fastening the strip, you can focus on the self-tapping screws with which the bars were screwed. So you will exactly hit the crossbar.

Then it remains only to fix a special perforated corner along the corner and level the irregularities.

It is also more convenient to level the dried putty along the arch of the arch with the entire plane of sandpaper fixed on a grater. It is unpleasant that dust falls into the eyes, so it is almost impossible to work without glasses.

How to make an arch instead of a door: third method - typesetting technique

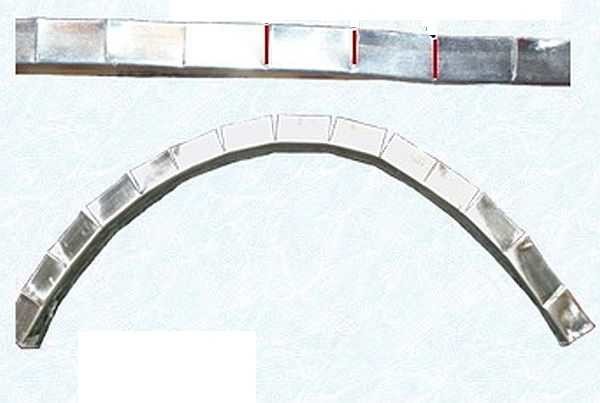

Another way to make drywall arches with your own hands is typesetting. The vault is divided into segments and assembled from pieces that create a curvature close to the required.

Attach them to a putty diluted with a mixture of PVA and water. Such a batch dries quickly, therefore, first we cut the plates and try on. It can be folded on the table, only the vault will turn upside down, but how correctly the plates are assembled will allow you to evaluate.

Then the plates begin to be attached to the opening, periodically reinforcing them with self-tapping screws for reliability. Washers are placed under the heads so as not to push the cardboard. Remove excess putty immediately. If it grabs, tearing it off is unrealistic. The finished surface is primed to improve adhesion (adhesion), and then putty, leveling the arch.To make it easier to display, you can use a template attached on both sides.

It is not easy to make sharp bends using this technology, and for rounded corners and semi-arches it is a great way to do without profiles.

How to bend drywall

One important detail: Standard wall drywall does not bend well. For curved surfaces, they specially came up with a thin one - 6 and 6 mm thick. This folded part is easier to make from it. With a slight curvature, such a thin sheet can bend easily and without tweaks. If there is no desire to buy a thin GVL, there are two ways to bend the standard one.

First - take a needle roller and roll the cut section well on one side. You need to roll with effort so that the plaster breaks. Then the leaf is moistened with water and left for two to three hours. After such procedures, he should bend well. Take it, fix it on one side, and gradually pressing it against the arch frame, bend it, screwing it gradually along the edges with self-tapping screws. The method is not bad, but only with a lack of experience and insufficient processing of gypsum, the sheet can burst. We'll either have to mask the gap later, or start over.

Second a way to bend drywall: on one side, make notches with a knife about every 4-5 cm. The notches should cut the paper. Such a strip is also gradually fixed, breaking the plaster as necessary. It bursts along the notch lines from light pressure.

Related Videos