How and what to finish aerated concrete inside and outside

Aerated concrete building can stand without external finishing without any damage to the integrity of the blocks (we are talking about autoclaved gas silicate). But, over time, dust settles on the surface of the blocks, and the previously white outer surface becomes an untidy gray with drips. So it doesn't matter, sooner or later, but the question arises about facing or finishing of aerated concrete outside. Inside, aerated concrete is finished almost immediately after construction: the blocks in the interior do not look very attractive.

It looks like aerated concrete without finishing in a few years

Since aerated concrete has a very high vapor permeability, there are certain nuances when carrying out finishing work. The fact is that practically all materials conduct vapors worse than gas silicate. This causes difficulties, since in order to ensure the normal removal of water vapor from the room, the vapor permeability of the walls - from the room - to the outside, must increase. Only special plaster mixes for foam concrete meet this requirement. But subject to certain rules, the finish can be any.

The content of the article

Exterior finishing of aerated concrete

First, about how you can not trim. Do not insulate with foam or expanded polystyrene, plaster the outside with ordinary sand-concrete plaster, paint with covering film-forming paints. As a heater, if necessary, you can use mineral wool, paint with paints that do not block the pores for moisture to escape from the wall. Now about what can be used to decorate the facade of foam concrete.

Curtain facades: lining, siding, panels, etc.

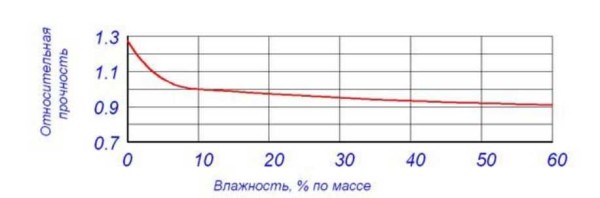

When finishing with any materials that are mounted on the lathing or guides, a gap remains between the finishing material and the wall. It is called ventilation, since in this interval, with the correct device, there is an active movement of air from bottom to top. The correct device is the presence of holes in the finishing material at the bottom and top. This ensures the movement of the air flow from the bottom to the top. This stream carries with it moisture, which is removed from the room. Such a device solves the problem of condensation, and also maintains normal wall humidity. Since at high humidity, aerated concrete has lower strength characteristics, maintaining its normal humidity contributes to a longer "life". The dependence of the strength of aerated concrete on the percentage of moisture is shown in the graph.

For exterior finishing of aerated concrete with a ventilated gap, most of the time it has a moisture content in the range of 10-15%, i.e. is in the optimal zone. To create such a gap, a crate is stuffed over the entire area of the wall, providing a distance of 3-5 cm from the wall to the outer finish.

An example of lathing for siding or lining

For the lathing, a wooden bar (treated with antiseptics) is used, metal guides are galvanized profiles for drywall or special ones for ventilation facades. The frequency of the location of the lathing is 40 cm.According to this principle, the facade is sheathed from aerated concrete with clapboard, siding, front panels.

When attaching the lathing to the wall, the question arises: what or, rather, "what for" to fasten the lathing to the gas silicate. You can just use self-tapping screws (black, they are stronger), but in order for the crate to hold well, you will need a large length. This means that metal penetrates deep into the body of the block. In winter, it is an excellent cold bridge. But this is not the worst.Under wind loads, the frame vibrates, vibration, of course, is transmitted to the fasteners. Under the influence of vibrations, foam concrete is crushed. As a result, the self-tapping screw may fall out.

And that is not all. Due to the temperature difference - the relatively warm aerated concrete and the rapidly cooling metal of the screw - condensation forms on the screw. When the temperature drops, it freezes, destroying the block body. In general, do not use just self-tapping screws for attaching the battens to aerated concrete from the outside.

Fastening a galvanized profile to hangers

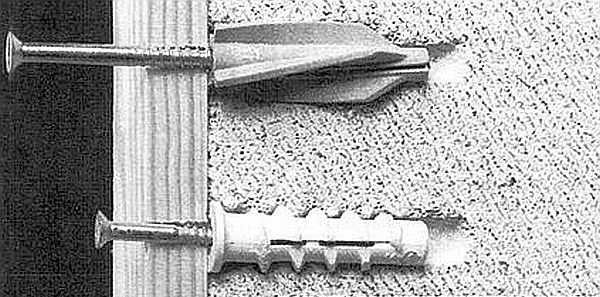

To avoid such a situation, plastic plugs are inserted into the wall and dowel-nails are used. The usual ones are of little use, although better than just self-tapping screws. If you use regular plugs, the length of the plastic plug should be at least 30 mm.

In general, it is better to fix it on special ones, which are called “for aerated concrete”. They are available in specialized stores selling hardware. They may not be found in the ordinary construction market. From the usual ones, they are poured with large plastic parts, as well as more developed screw plates.

Types of plugs for gas silicate

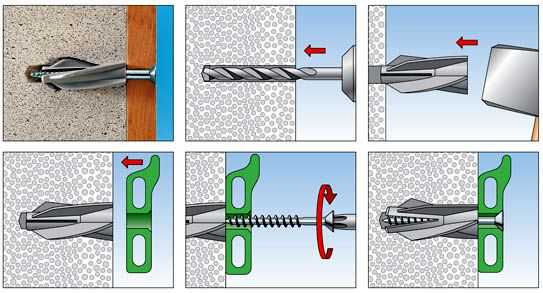

The installation method is standard. A hole is drilled under the dowel plug (plastic part). Depending on the shape of the screw surface, the upper dowel is driven into it (in the photo) or the (lower) plastic insert is screwed into it. Then the screw is screwed in.

How to install a dowel in aerated concrete

When using wooden blocks or galvanized profiles, they are attached to such dowels. The pitch of the lathing is less than usual - it is about 40 cm. This is for a more even distribution of shock loads that occur in strong winds. An example of aerated concrete siding can be seen in the video. There are many useful nuances.

Brick finishing

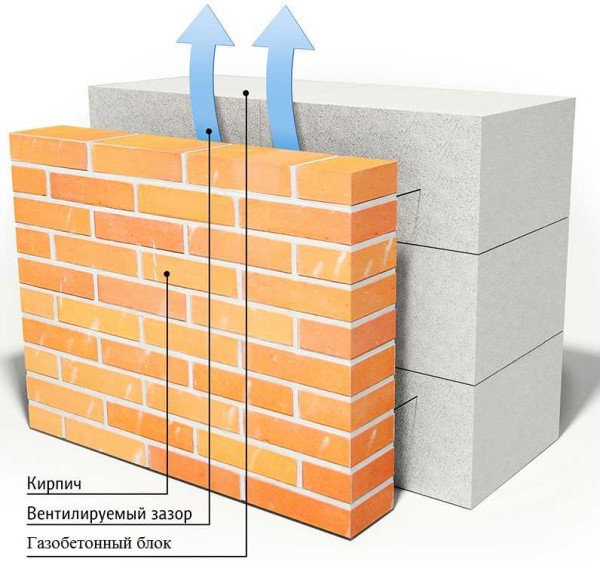

If you lay a brick facade of aerated concrete correctly, it will stand without problems for decades. A prerequisite is that there must be a ventilation gap between the wall of the finishing material and the aerated concrete wall. Its width is not less than 30 mm. In order for it to work, when laying the finishing brick, air vents are left in the lower part - small holes into which air will enter. To prevent animals from getting into them, they are covered with ventilation grilles.

The principle of "operation" of the system with a wall of finishing bricks spaced 3-5 cm

Only this type of finish, in contrast to ventilated facades, should be taken into account when calculating the foundation. Firstly, the mass of brick finishing, even in half a brick, is considerable, and it must be taken into account when calculating the bearing capacity of the foundation. Secondly, the width of the finish is taken into account when determining the width of the foundation: the overhang of the brick cannot be more than 3 cm, and a ventilation gap of 3 to 5 cm between the wall and the finish is also needed.

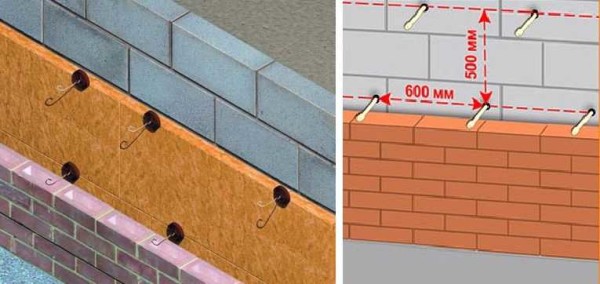

But, if you just put a brick wall at the required distance from the wall of the house, it is very likely that it will simply fall. Therefore, it is necessary to tie the walls of foam concrete and brick. To do this, even at the stage of laying the foam concrete, thin plates are installed between the blocks, which are called "flexible ties". Best of all - if they are made of stainless steel. The medium in the solution in which these strips are immersed has an alkaline reaction, and in an alkaline medium, metal, even galvanized metal, is rapidly destroyed.

Mounting plates inserted into the seams for connection with the brick finish of aerated concrete, but they are galvanized and after a few years the brick finish may fall off

Plates on the surface of the wall are placed about 60 cm apart in every second row, the maximum distance in height between two rows is 50 cm. Plates are staggered. In the area of corners, window and doorways, it is worth placing them more often.

Sometimes when laying, they forget about the plates. In this case, a dowel is screwed into the wall, to which a perforated metal plate or also a special stainless hairpin is already attached.Another option: during bricklaying, strictly opposite the seam, a hole is made in the wall into which a hairpin is driven. The hairpin should go 10 cm into the concrete body and almost the entire width of the brick. But the hairpin is not flexible and can break both aerated concrete and brick trim (exactly in the brick floor). Therefore, it is better not to suffer from such "economy". How is the finishing of aerated concrete using finishing bricks with a ventazor - in the video.

How to plaster aerated concrete facade

As already mentioned, plasters for aerated concrete can only be used with high vapor permeability. These plasters are expensive, but applied in a thin layer; therefore, a number of preparatory measures are required to obtain an even surface.

Plastering can be started when the moisture content of aerated concrete blocks is not higher than 27%. Before starting work, the surface is processed:

- dust-free with a brush;

- the surface is leveled with a float;

- dents and chips are sealed with glue mixed with aerated concrete dust, which was obtained when cutting blocks.

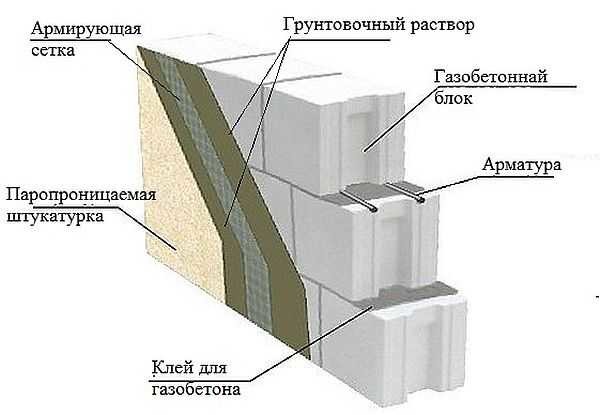

The minimum layer - up to 10 mm, can be omitted. Due to the adhesive additives in the composition, it will adhere tightly to the surface. If the layer is 10-15 mm, reinforcement with a fiberglass mesh is necessary, with a thickness of 15-20 mm, a metal painting mesh is required. Exterior finishing of aerated concrete with plaster of greater thickness is impractical.

The mesh for outdoor use should have a mesh of about 3 mm. It must be resistant to alkaline environments (written on the package), otherwise after a couple of months it will lose strength and stop holding the plaster. As a result, the finishing layer will fall off.

Finishing aerated concrete with plaster outside

Reinforcement is carried out over the applied layer of the primer mixture. It is also used special, has excellent adhesion to foam concrete, creates a basis for applying decorative plaster. The composition is applied to the wall in a strip. While it is not frozen, the net is rolled onto it. Using a notched trowel or float, the mesh is pressed into the mortar. After it is completely immersed, take an ordinary wide spatula and level the surface, adding mortar if necessary. The leveled surface is left to dry. The term depends on the material used and is indicated by the manufacturer. The average period is 7 days.

A primer is applied to the dried surface of the reinforcing layer. It performs several functions:

- evens out the absorbency of the base (reduces it);

- paints over gray (it is white);

- reduces porosity.

On the dried primer (available in the description), the finish is applied - decorative plaster. The technique of its application depends on the type of composition.

Insulation of walls made of aerated concrete

With normal calculation and adherence to technology (laying on glue with a seam thickness of 1-2 mm), gas silicate walls do not need insulation. In central Russia, there is a sufficient block thickness of 325 mm. If, nevertheless, the need arose, the insulation must be vapor-permeable. And this is mineral wool and foam glass. Foam glass has excellent characteristics, but a high price. Mineral wool is cheaper. The thickness of the insulation depends on how cold it is in the house, but usually the minimum is 50 mm.

When finishing with a crate, it is made from a wider board or profile, taking into account the fact that the thickness of the insulation is also added to the thickness of the ventilation gap. Sometimes a counter grill is needed. These are additional planks, which, depending on the circumstances, are stuffed along or across the first lathing. Thermal insulation is attached to the wall with special plastic dowels with a wide mushroom-shaped head.

Interior finishing of aerated concrete

Indoor aerated concrete finishing has its own characteristics. Most often, such walls are still plastered. It is possible to use the same expensive mixtures as for outdoor decoration, but it is very expensive. There are ways to make walls normally using ordinary cement or gypsum plaster.But this requires additional measures: a preliminary relief is created using cheap tile adhesive. It has good adhesion (adhesion) even with a relatively flat surface of aerated concrete, it creates an excellent basis for applying subsequent layers. plaster. The procedure is as follows:

- We reduce the hygroscopicity of aerated concrete. If you apply any plaster to an unprepared block, it will not have time to "grab", since aerated concrete will very quickly absorb all the moisture. The layer will just crumble. Therefore, first, the walls are cleaned of dust, then they are covered with a deep penetration primer. Requires two coats. The first one dries for about a day (depending on humidity and temperature).

You can prime the walls with a roller, or you can pour the composition into an ordinary garden spray

- Apply a layer of tile adhesive 3-4 mm thick.

- We reinforce it with a fiberglass mesh with a mesh of 3 mm (we put the mesh on fresh glue and press it inward).

The reinforcing mesh is pressed into the applied layer of glue

- Form a horizontal relief with a notched trowel.

Wall prepared for plastering

- Leave to dry for a few days.

On dried glue, you can apply plaster, or you can lay tiles. She will definitely not go anywhere: she will hold on well. In wet visits - bathroom, kitchen - you can choose a film-forming primer, which reduces the vapor permeability of paints.

For information on how to properly prepare a gas silicate wall for plaster, see the video. With its help, plastering of aerated concrete walls with your own hands is understandable: everything is painted in steps and chewed.

Interior finishing options

For the decoration of walls made of aerated concrete inside, almost all options are acceptable:

- Drywall or gypsum plasterboard on bars or profiles. There are already no difficulties with fastening: no wind loads, no frost. But, this is only if we are talking about a permanent residence. At the seasonal unheated summer cottage and inside, the installation of dowels is required.

- Lining in all its forms.

- Plastic panels.

- Painting, but on a prepared and leveled surface. And paints are still better with at least some vapor permeability. Unless in the bathroom or in the kitchen, you can use film-forming compounds.

Of all these processes, only painting requires some explanation. For this type of decoration, a wall of aerated concrete does not have to be plastered. In general, the walls should be almost flat. If there are chips, dents or protrusions, the solution is very simple. They are sealed with the same glue on which the blocks were placed. If the dents are large, you can add sawdust to the glue, which is formed when the block is cut. The seams are rubbed with the same composition.

Leveling the surface for painting

If there are protrusions, they are cut off with a special float, but you can also use sandpaper fixed to the bar. With these means, they achieve a flat surface that can be painted. The wall is cleaned with a brush attached to the holder - dust is swept away. The dust-free wall is primed. The primer is selected compatible with the selected paint. They must be compatible. It is desirable to apply the primer two times. Then paint is applied on an absolutely dry primed surface.

The house in the uppermost picture is already 77 years old, it was built in 1939)))

Helpful information collected, thank you!

In fact, they helped a lot, I learned many of the nuances from you.

Glad to be helpful))

thank you very much! briefly about the main thing!

Great article! Many nuances were revealed. Thanks for your work !!

Thank you for your kind words. We try to be helpful.

foam glass is practically vapor-tight, it cannot be recommended to use it for insulating aerated concrete, unless only indoors

Thanks for the useful material, but he still scared me a little - I bought a house for rough finishing from gas-silicate blocks, the facade has already been formed and, as I understand it, with unwanted polystyrene foam, followed by decorative facade plaster Knauf. I did not notice the gap between the insulation and the blocks. Now I plan to start interior decoration. What is the best option? And how critical is everything?