Fiberboard (fiberboard): what kind of material, types and application

Wood in its pure form has recently been used less and less. Even for us, the material is becoming too expensive, and processing is difficult. More and more wood-based materials are used at construction sites. One of them is fiberboard (fibreboard). They are used in construction, decoration, furniture making.

The content of the article

What is fiberboard, scope

Fibreboard is an abbreviation of the name "Fiberboard". It is a sheet building or finishing material. It has a relatively low price, it can be of different density - soft, hard and superhard. Sheet thickness - from 2-3 mm to 12-15 mm, some types can be up to 40 mm.

Fiberboard sheets are distinguished by high density and strength, and have a relatively low price. Thin sheets bend perfectly, which allows them to be used for sheathing curved surfaces. Fiberboard is used in construction, as a cladding for frame house building, for leveling the floor, walls. Also, partitions in railway passenger cars are made of this material.

Low density fiberboard is used as sound insulation material. The chaotic arrangement of the wood fibers makes the sounds "bogged down" in the material. This is the most inexpensive and easy-to-install type of soundproofing materials. There are more effective ones, but cheaper ones still need to be looked for.

Some types of fibreboard can be used as finishing materials - for finishing walls in rooms with normal humidity. For these purposes, fiberboard is used, one of the sides of the sheet of which is painted, covered with a decorative film, and laminated.

Another area of application of fiberboard is furniture production. Usually this material is used as an auxiliary material - they make the back wall of cabinet furniture, hem the bottom in armchairs and chairs, the bottoms in drawers, etc. In general, the scope is extensive. In fact, there is only one drawback - without hydrophobic additives, the material behaves poorly at high humidity. It swells as it grows in size. At the same time, sheet material “goes in waves”. When dry, it remains deformed. So in unheated or humid rooms, only certain brands of fiberboard can be used.

Production technology

The initial raw material for the production of fiberboard is the waste of the woodworking industry: wood chips, sawdust, fire (lignified parts of the stems of spinning plants). The raw material is washed, foreign inclusions are removed from it, then dried. The dried material is crushed in special machines (defibrators and refiners) into the smallest particles - fibers. The fineness can range from coarse to fine. Further, the process is different for different production methods.

Pressing is carried out under high pressure - 3-5 MPa and high temperature - above 300 ° C. Due to this, the material is bonded and compacted. Before pressing, additional components are added to the starting material that change the properties of the material - binders (synthetic resins), water repellents, fire retardants, etc.

Forming methods

There are two ways to produce fiberboard - wet and dry pressing. The “wet” method is more environmentally friendly.In wet pressing, less binders are used (sometimes, without synthetic additives at all), but the material is more expensive, since the process is more energy intensive. It takes up to 15 minutes to dry one sheet, which limits the productivity of the presses and therefore increases the cost of the material. With this method, the necessary additives, water, are introduced into the crushed material. The slurry enters the dispenser, which spreads it in an even layer on the belt. For faster removal of water, the tape has a mesh structure. After passing through the press, the back side of such fiberboard has an imprint of this fine mesh.

With wet pressing, some types of fiberboard can be made without the addition of an external binder. Under pressure and at high temperatures, lignin (a substance that characterizes the stiff walls of plant cells) is released from wood fibers. It is a natural binder. Lignin is found in significant quantities in softwood. But not for all types of fiberboard, a natural binder is sufficient. In this case, 4 to 7% of a synthetic binder is added.

When dry pressing, synthetic resins are usually added to the mass, which bind the fibers. It is this method that makes it possible to obtain fiberboard of a large thickness - up to 12-15 mm, some plants can produce pits up to 40 mm thick. The compaction and pressing of the dry mass takes much less time - 3-5 minutes, depending on the class and thickness. The productivity of the press increases significantly. In addition, fewer additives are added to the dry mass - they are not washed out with water. All this leads to a reduction in material costs. But cheap binders contain formaldehyde, and its content must be controlled, as it is harmful to health in large quantities.

For the production of furniture and interior decoration, material with formaldehyde emission class E0.5 or E1 must be used. This is, as a rule, wet-pressed fiberboard. Wet fiberboard can be distinguished by the mesh print on the back of the sheet (see photo above).

Final processes

During high-temperature pressing, the particles stick together. The time spent under the press is not always sufficient, therefore, the already formed sheets are transferred to a special chamber, where the material "ripens" at high temperatures. Fiberboard is kept here for several hours. During this time, the fibers are sintered, stick together, the material becomes homogeneous and strong.

The slabs come out of the chamber, with practically zero humidity and begin to actively absorb moisture from the air. As a result of this process, the edges of the sheets swell. To avoid this disadvantage, the material is transferred to another chamber, where it is brought to normal humidity. And only after that, the sheet fiberboard can go on sale or to other machines - for painting, lamination.

The good thing is that the fiberboard technology is plastic. The press can have any shape, which allows you to make not only sheet material, but also shaped products. For example, skirting boards or furniture fronts.

Types and classes

The main classification of fiberboard is by purpose and by density. By design, fiberboards are of general and special types. Special - this is with some special properties. Three main groups can be distinguished:

- Moisture resistant (bituminous). When preparing the mixture, bitumen is added to it, which improves its resistance to moisture.

- Hardly combustible. Fire retardants are added to the starting material, which reduce the flammability of the finished material.

- Finishing - with a refined one side.The front side of the fiberboard can be painted, glued with a polymer film imitating various materials: wood, stone, brick, tile, etc.

It is customary to refer to materials for special purposes and finishing types of fiberboard - with a refined one side. There are a lot of subspecies and they can be called differently:

- Fibreboard with veneered or painted surface, smooth on the back (produced by dry pressing). In colloquial speech, such material is usually called "hardboard". Usually this is a medium density material.

- The same, but with an uneven back surface called "masonite" (wet pressing).

- If the front side of the material is glued with a film - laminated - such material is called laminated fiberboard, sometimes the abbreviation LDVP is found.

Fiberboard for general use is also called construction. This class can include materials for both dry (with two smooth surfaces) and wet production methods.

Price or quality?

Usually, the main criterion when choosing a general-purpose fiberboard is a low price. If you use it for sheathing the frame, you need a lot of material, so you want to save money. But do not chase cheapness.

Cheaper fiberboard sheets are produced with more formaldehyde. This substance in large quantities contributes to the development of cancer. To keep the house safe, you should not use material with an emission class higher than E1 for interior cladding. E1 grade materials are absolutely safe. They emit as much formaldehyde as natural wood.

Density, weight, thickness of sheets

The technology for the production of fibreboard allows making them of different densities. Depending on the density, they have different technical characteristics and field of application. There are such types of fiberboard:

- Low density. They are also called soft, they can be designated using the attached letter "M" - DVP-M. Quite loose material with a density of 200-350 kg / m³. Sheet thickness can be 8, 12, 16, 25 mm. If desired, you can find up to 40 mm. They are usually used for soundproofing or as finishing / covering in places that are not subject to stress.

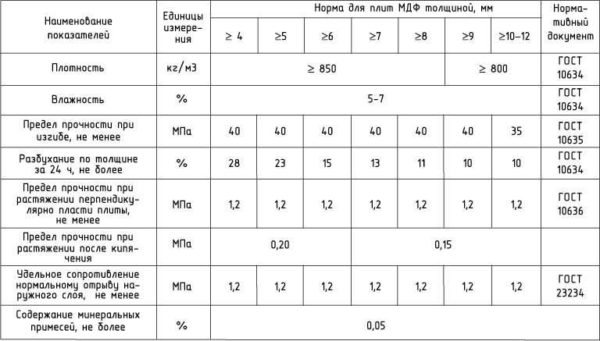

- Average density - up to 850 kg / m³, sheet thickness can be 8, 12, 16, 25 mm. According to the classification, they also pass as soft.

- Semi-solid - from 860 to 900 kg / m³, sheet thickness 6, 8, 12 mm.

- Hard (fiberboard T) - 950 kg / m³, sheet thickness 2.5, 3.2, 4.5 and 6 mm.

- Superhard (DVP-ST) - 960-1000 kg / m³, can be 2.5, 3.2, 4.5 and 6 mm thick.

Hard and superhard grades are used where resistance to mechanical stress is important. In household construction and decoration of houses / apartments, DVP-T is placed on the floor, they can sheathe walls with them.

Types of hard slabs

For all that, general-purpose solid fiber boards are of several types - with different front and back sides. According to GOST, solid fibreboard has the following marking:

- T - hard slabs with an unrefined front surface. Often also called "technical" fiberboard. Used for works in which appearance is not important.

- TP - hard boards with a tinted face layer. This is the so-called hardboard. It is used in the furniture industry for rear panels in cabinets, tables, etc.

- Т-С - hard boards with a top layer of fine wood pulp. One side of the sheet is the same color, but smooth, like varnished. It can be used for cladding frame buildings from the inside. Requires minimal finishing work. On such a surface, a rhinestone can be glued wallpaper, but it will be very inconvenient to remove them. But the putty on the smoothed surface lays down badly - it rolls down.

- T-SP - hard boards with a tinted front layer of finely ground wood pulp.It can be used as a finishing material.

Grades of solid fiberboard can be of two classes - A and B. They are distinguished by quality. As you can see, even in the same class there are different materials. With the same (or almost the same) technical characteristics, they have different areas of application.

Subtypes of superhard fiber boards

Superhard fiberboards are rarely used in household construction and repair - the price is too high, and high density and stiffness may not be in demand. Excessive rigidity can sometimes be uncomfortable.

According to the standard, there are two types of such material:

- ST - "construction" brand, not too attractive in appearance;

- ST-S - with a smooth top layer - finely ground wood pulp is compacted to a very smooth state.

There are practically no laminated or decorative types - too heavy and tough material for finishing is also not needed.

Names by density

Also, fiberboards have different names depending on the density. This is usually a tracing (transliteration) of English / international names. Although, under the same name, other countries often mean different material.

- LDF - from English low density fiberboard - LDF. Translated - low density fiberboard. In fact, this is the name for a medium density material that simply has characteristics at the lower boundary of the zone. It has nothing to do with soft wood boards.

- MDF - from English medium density fiberboard - MDF. In translation - medium density fiberboard. If we talk about standards, then this material corresponds to the GOST definitions of medium density fiberboard.

- HDF - hightdensity fiberboard - HDF. According to the characteristics, it is possible to match the brand of DVP-T (solid).

As you can see, there is no clear distinction. Misuse of the names adds to the confusion. In general, each time it is necessary to clarify what exactly the speaker means by this or that term.

Dimensions

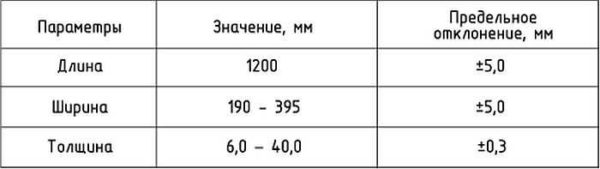

It makes sense to talk about sizes only with respect to standard sheets or plates. As mentioned earlier, the thickness of fiberboard sheets can be from 2 to 40 mm. Other dimensions are defined by standards:

- width 1220 mm and 1700 mm;

- height 2140 mm, 2440 mm, 2745 mm.

Please note that in any production, you can find non-formatted sheets. After forming in the press, they are trimmed, and sometimes, due to malfunctions of the equipment (which forms the carpet on the belt), you have to trim more edges. Because of this, narrower or shorter sheets are obtained. If you don't care about the standard size, you can always buy these. In terms of quality, they are unlikely to differ in anything, but at a price they will be much lower.

Modern use of some species

If we talk not about construction, but about finishing works, then more and more often in this area the name “MDF»- medium density fibrous material. Interior doors are made of laminated sheet MDF. A frame made of wooden planks is sheathed with this material, getting budget products that look very good. Sound insulation characteristics depend on the type of frame filling, and the durability of the product itself depends on the quality of the lamination and the rigidity of the film.

The production technology makes it possible to create not only wood-fiber sheet products. The form of the press, in theory, can be any. Therefore, various kinds of moldings began to be made from MDF - platbands for finishing the same door frame, baseboards and other similar products. They can be matched to the door color and similar in shape.

Facades of cabinet furniture began to be made of MDF. For example, kitchens.Moreover, if furniture made of chipboard has a linear structure, curved, smooth, rounded shapes are formed from crushed wood fibers. All this allows you to create a greater species diversity. Using the same technology, MDF wall panels are made. These are not only even smooth sheets, but also with a pattern of different types / types.

Rigid fibrous materials

In some areas, HDF, a high density material, is used. In particular, due to its rigidity, it is convenient to work with it when forming an openwork. Using laser cutters, a cut openwork is formed on thin laminated or painted HDF boards. Various decorative elements are made from openwork plates, in particular - screens for radiators.

Some types of finishing materials are formed from HDF. The board is covered with a layer of film or painted. The surface can be plain painted, imitate wood, stone surface, etc. If the material is molded in the form of strips with locks, you get the same laminate. If the material is made in the form of sheets - they can sheathe walls, ceilings, use to decorate the working area in the kitchen - kitchen apron.

Surely there are other areas of application of fiberboard of different density. And there will likely be other uses as well. The technology is flexible, it allows to obtain materials of various properties.