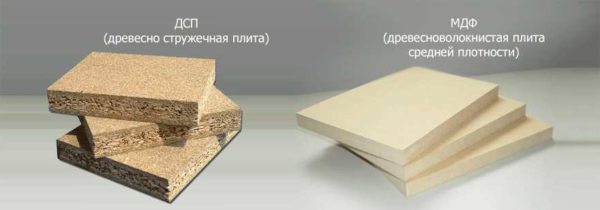

What is MDF, how it differs from chipboard, where it is used

With the development of technology, more and more building and finishing materials appear on the market. At the end of the last century, we got MDF. There are MDF boards that are used in construction work, there are finishing panels that can be used to decorate walls / ceilings or make furniture.

The content of the article

What is MDF and the method of its manufacture

MDF appeared on our market in the last years of the last century, and it was invented in the USA at the end of the 60s of the 20th century. You can understand what MDF is if you translate its English name - MDF -Medium Density Fibreboard. It translates into Russian as "medium density fiberboard". That is, the Russian-language name was formed with the help of transliteration - instead of Latin letters, they put similar Russians. A common phenomenon for our language.

Manufacturing process

MDF is made from wood, ground to the state of very fine chips, practically - to the state of fibers. Mostly wood waste is used, so the release of this material does not harm forests.

Milled wood is cleaned of sand and other impurities, washed, dried. The prepared mass is heated, a tape of the required width is formed from it, and then pressed. Under pressure, a natural binder, lignin, is released from the heated wood fibers. It is he who is the binder in this material. The final shape of the products is passed in a finishing press, which squeezes out the remaining air from the mass, forming a homogeneous MDF structure.

After pressing, the cooled material is fed to grinding, where flaws on the surface are removed from the MDF, the material is brought to the required thickness.

Not all wood species provide sufficient binder. Then add a similar, previously isolated, lignin or other natural binder. MDF is considered the safest of all wood-based panels, since the binder is natural, and the formaldehyde emission is comparable to that of wood (emission class F1, that is, it is allowed to use it for the manufacture of furniture for children's and medical institutions).

Fiberboard can be produced with special properties. Basically, moisture resistance additives increase moisture resistance and reduce flammability.

Appearance and release forms

In its "pure" form, the material has a grayish-brown color, on the cut a homogeneous dense mass. The exact shade depends on the type of wood crushed and the amount of bark. In this form, the material is used as sheet building material - for the construction of light partitions, leveling walls.

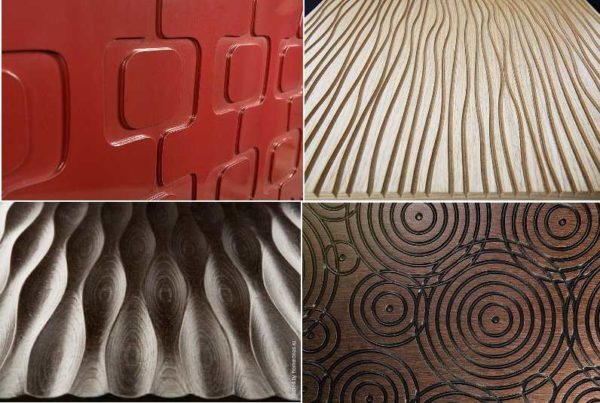

The surface of MDF can be "refined". It can be painted, laminated with PVC film, pasted over with veneer or plastic. This gives a fairly large number of design options that are used in the furniture industry, in the production of finishing materials.

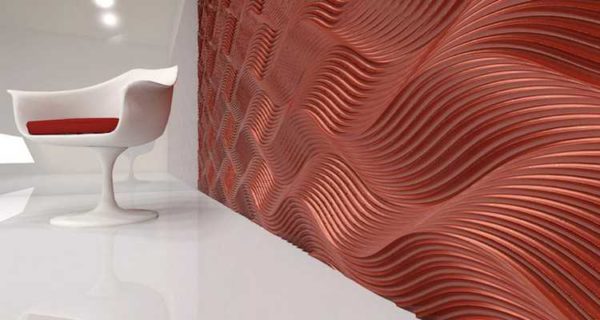

The production technology allows you to form products of various shapes, thicknesses, sizes. During finishing pressing, a certain relief can be formed, which is used in the manufacture of furniture and doors. Also, finishing materials are made from MDF - plates, panels. They make skirting boards, platbands, and other moldings from it. All these materials can be used for interior decoration.

The structure of MDF is fine-grained, dust is formed during milling, which makes it possible to make carved products. It is used in the manufacture of carved decorative elements - panels, screens for heating radiators, decorative lattices, curly furniture facades.

MDF or chipboard - which is better?

Having entered the market, MDF created competition Fiberboard... This was facilitated by its properties:

- with the same thickness of MDF, twice as strong Chipboard;

- the mass is very plastic and allows you to form reliefs of any complexity;

- easier to handle;

- a homogeneous smooth surface makes it possible, even when painting and laminating PVC, to obtain a good appearance, suitable for the furniture industry;

- has a lower formaldehyde emission factor;

- does not change shape when temperature changes.

All this led to the growing popularity of the material. Even despite the fact that MDF is more expensive than chipboard. To some extent, MDF even competed with wood. For example, skirting boards, MDF trims, finishing panels are increasingly being used. This is due, firstly, to a lower cost, and secondly, to greater practicality. Wood requires regular maintenance - painting, varnishing. MDF does not require special care. It is simply wiped off with a damp cloth, using a liquid detergent if necessary.

MDF boards

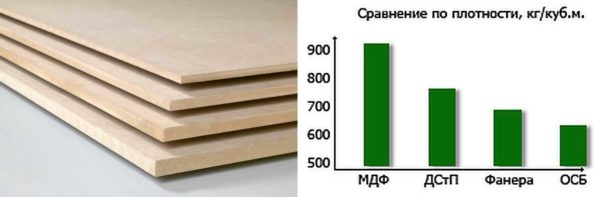

The manufacturing technology of the MDF board allows you to vary the density over a wide range: the minimum indicator is 760-780 kg / m3, maximum - 1100 kg / m3 and even higher. A material with a lower density is used where the abrasion load is low: in the furniture industry, for wall and ceiling decoration.

High density MDF boards are used for floor finishing. The material of this category has high abrasion resistance: one and a half times higher than that of oak (oak - 6.9, MDF - 10-11). If we add that the coefficient of diagonal warpage is only 1.2 mm per meter of diagonal (15 mm for plywood), it becomes clear that furniture makers and finishers love this material.

Dimensions and tolerances

One of the most popular forms of release is slabs of various thicknesses and formats. They can be found with the following parameters:

- thickness - from 3 mm to 40 mm;

- width 2800 mm;

- length - 1250 mm, 2170 mm.

It is convenient to work with MDF boards, since this material has very small tolerances for deviations from dimensions:

- the difference in thickness cannot exceed 0.2 mm (for plywood, 0.5-2.5 mm);

- the length may differ by no more than 5 mm;

- the take-off in width cannot be more than 2 mm.

When two sheets are joined, the difference in thickness or size is very small or not at all. Therefore, MDF finishing with sheets or panels is progressing quickly.

Types of surface finishing of sheet material

MDF boards are available with different types of surface treatment:

- Sanded. Grinding can be on one or both sides. Such material is good for painting, applying putty. If you use it to level the walls, it is desirable for light wallpaper putty, then prime. Thick wallpaper can be glued over the primer without puttingtying.

- Laminated (covered with PVC film). Usually lamination is done on one side, but you can also find double-sided lamination. Usually the film repeats the color and texture of various wood species, but it can also be smooth - matte or glossy. This type of material is used for the production of furniture, decorative wall panels. From the laminated subspecies (also called LMDF), cabinet furniture is made for living rooms, kitchens and even bathrooms. Moreover, for the facades of kitchens they use the usual one, for the countertops and furniture in the bathroom - moisture resistant with hydrophobic additives, which give increased resistance to water and steam.

- Veneered. MDF boards are pasted over with the finest cuts of valuable wood species - veneer. The appearance is very similar to solid wood. The disadvantage of this type of material is the high price. Of course, it is lower than similar solid wood products, but not as low as veneered chipboard.

- Papered with plastic. Another type of finish that is mainly used in the furniture industry.

If we talk about construction and repair, then they use sanded MDF boards. When leveling walls or installing lightweight partitions, when leveling the floor and ceiling. Here is an approximate area of their application.

Frame mounting

If the surface of the walls or ceiling is uneven (deviations are more than 1 cm), the method of mounting sheet MDF is the same as for drywall - on the frame. The frame is usually assembled from wooden blocks, but no one forbids placing profiles under drywall. The cross-section of the bars is selected based on the unevenness of the wall - they must compensate for all the height difference. You will most likely need 20 * 30mm bars or something. They are stuffed horizontally with a step of 40 cm. With this step, the joints of the sheets (they are, if the ceiling height is higher than 280 cm) fall on the bar.

For the installation of sheet panels from the same bar, vertical jumpers are installed. They are placed in steps:

- 54.3 cm - for sheets with a width of 2170 mm;

- 42.3 cm or 63.5 cm for 1270 mm width.

The spacing of the vertical jumpers depends on the thickness of the selected material. For thin sheets (3-4 mm) it should be less, for thick ones (5-6 mm) more can be done.

MDF sheets / plates are attached to the assembled frame. The peculiarity (in comparison with drywall) is that for hidden fastening it is necessary to drill holes for fasteners. Otherwise, fasteners will not go into a dense slab. To prevent the caps from sticking out above the surface, the hole is expanded under them using a larger diameter drill.

After installing the screws, holes remain on the surface. They are sealed with putty. If further puttying of the walls is supposed, act as in installation of drywall - first, the holes are filled with putty, immediately removing the excess with a spatula. After drying, the places of putty pass with fine-grain sandpaper - in order to finally get rid of possible irregularities. Then, after dusting the surface, they begin to putty the walls.

Installation on glue

If the walls are even, you can mount MDF boards without a frame - with glue. You can use liquid nails or a compound such as CM-11. The procedure is as follows:

- The composition is applied to the surface of the sheet in a zigzag or islets.

- They put the sheet against the wall, press, align in the plane. Align by tapping on the protruding parts with a fist, while checking the position using a level (you need to control the vertical and horizontal).

- Hold in the desired position for several minutes.

- Install the next sheet.

- After the glue has dried, the joints are sealed with putty.

So that during the installation process the sheet does not move anywhere, you can make holes in the corners and, after alignment, fix the sheet. Even if the self-tapping screw will only stick in the plaster, this will help, since it is required only at the initial stage - until the glue begins to harden.

This method seems simpler and less costly (due to the lack of a frame), but it is not at all easy to align bulky MDF boards. Better to try on a small section of the wall. The point is that it is impossible to disassemble the established. Only if you destroy the skin completely. So it's worth considering which method is best.

Installation of MDF sheet on the floor

For laying on the floor, choose high-density moisture-resistant MDF boards (from 900 kg / m3 and higher). Sheet thickness - from 5 mm when laying on a subfloor and from 10 mm when installing on logs.In this case, the installation method is similar to leveling the floor with plywood, only the gaps are smaller, since the wood board changes its parameters much less plywood. The rest of the rules are the same:

- First, the base is leveled into the horizon and cleaned.

- Plates are laid with a gap of 2-4 mm from the walls.

- When laying, follow the mismatch of the seams (staggered laying).

- The expansion joint between the plates is left 2-3 mm.

- Fasteners are installed along the perimeter with a step of 10-15 cm, in a plane - with a step of 20-25 cm (or along the log).

- Holes are drilled under the fasteners, with an extension under the head.

- The holes after the installation of the fasteners and the joints are sealed with putty.

After sanding the putty, the surface of the MDF floor is ready for painting. If you do everything carefully, you get a perfectly flat floor. This base can also be used as a base for flexible finishing materials or for laminate.

MDF finishing panels

Finely dispersed pressed boards are used as the basis for the production of decorative finishing panels. The front surface is pasted over with paper. This is the cheapest option. Slightly more expensive ones are laminated with PVC film. There are also veneered panels. This is the more expensive material. There are also options with plastic, but very rarely.

Decorative MDF panels are most often sheathed on walls, sometimes - on a ceiling. This method of finishing saves time: the surface is leveled and immediately takes on the final look, since no additional finishing is required.

Types of decorative MDF panels

It will not be about colors and shades, but about the shape of the inlet and the type of decorative surface. In shape, the finishing panels made of pressed wood fibers are:

- Rack type. The length is many times the width. Length 2.0 m - 3.0 m, width 150 mm to 250 mm. When choosing, pay attention to the panel thickness (3 mm to 9 mm) and the depth of the lock. Ideally, the lock (protrusion) should be at least 5 mm. In this case, joining the planks will be easy and hassle-free. They are mounted on a frame, fastened in a tongue or groove with self-tapping screws.

- Tiled type. Rectangular or square slabs. The maximum dimensions are meter by meter, but rectangles with different aspect ratios are more common. They are mounted on the frame or directly to the walls using a special system of secret fasteners, the fragments of which "cling" to the projections of the slabs.

- Sheet panels. They are rarely used for decoration of premises, more often - for cutting in the manufacture of furniture. But, if necessary or desired, they can also be used as a decoration, more often installing clamps.

When choosing MDF panels, pay attention to the type of finish. The cheapest material is covered with paper over which a thin layer of protective coating is applied. It is clear that such a surface is quickly scratched; it can only be wiped with an exceptionally soft, slightly damp cloth. You cannot even use a rough sponge, otherwise light spots will form. Such MDF panels are good for finishing the ceiling - there is no mechanical load at all. If you install them on walls, it is better to immediately cover with two coats of varnish. You choose the type of surface yourself - gloss, semi-gloss, matt, semi-matt ... It is important that the film is strong.

More expensive ones - with PVC and veneer - do not require additional finishing, but at a price 2-3 times more expensive. If your budget is tight, the above is not a bad option.

Installation methods

MDF panels are mounted either on the frame, or directly on the wall, using glue. The technology is described in the previous paragraph and differs only in that for installation, clamps are used - special fastening plates for secret mounting. The first panel on the wall is installed in the corner.Here it is fastened through and through with self-tapping screws. All others are fixed with clamps. After the installation is completed, the corners are closed with a special corner profile. It is mounted on glue - applied in a thin layer and pressed at the installation site.

There is also a system of profiles - starting, finishing, connecting and corner (outer and inner corner). But this fastening system is more expensive, it is used with MDF panels finished with veneer, square or rectangular format.

There is one more subtlety of mounting decorative MDF panels on the ceiling. If you use thin sheets / strips - 3-4 mm thick - you need to put suspensions often, otherwise the material will bend under its own weight. When using 6-8 mm thick slabs, suspensions can be installed less frequently. They are more rigid and do not bend. But the weight of the trim will be greater, so you will have to use more powerful guides and the hangers themselves.