Geotextile (geotextile): purpose, properties, application

Technology does not stand still and very often new building or finishing materials appear. One of them is geotextile. This material has appeared quite recently, but it is already advised to use it with the device foundations, paths, roads, land improvement.

The content of the article

What is geotextile?

Under the name "geotextile" is a group of materials for various purposes, composition, production method and even type. Most often they are laid "on" or "in" the ground. The main component is synthetic threads or fibers. These materials are durable and relatively inexpensive. In some cases, fiberglass is used in production, sometimes natural materials are added to synthetics - cotton, wool. All this changes the properties and characteristics of the material, affects the area of use.

Raw materials for the manufacture of geotextiles

The most common are polyester and polypropylene geosynthetic materials. Polypropylene has a denser structure, usually higher tensile strength, less fluffy in appearance. The lack of polypropylene - it reacts poorly to ultraviolet light - becomes brittle. Therefore, it is better not to use it as a covering material.

Polypropylene geotextiles can be of any color, since dyes can be added to the feedstock. The base is white, but more often the color changes due to additives that are added to obtain special properties. For example, in order for geosynthetics to tolerate sunlight better.

Polyester geotextiles can be made from recyclable materials (plastic bottles, etc.), which is why they are usually cheaper. Polyester yarns do not get long, so the material is more “shaggy” and less tear-resistant. Any color, but more often gray (Dornit brand), black, beige or brown, very rarely white. This is when it is made from virgin raw materials.

Geotextile "Dornit" is a nonwoven, needle-punched material with high strength. Made of synthetic fibers, the fabric is rolled into rolls of 50 meters and in this form goes on sale. Due to its strength, resistance to wear and a fairly democratic cost, "Dornit" is actively used in the construction industry and landscape design

To summarize, polypropylene geotextiles should be used where high strength is needed - when constructing roads, paths, strengthening slopes, foundations, and fillings. Polyester material - suitable for garden beds, flower bed, slides and other landscape tweaks.

Production methods and basic properties

There are three different ways to make geotextiles:

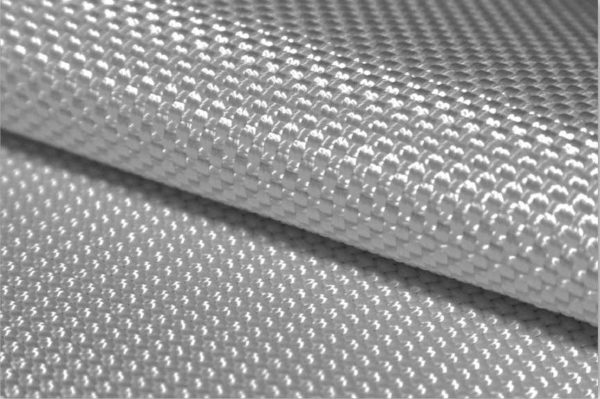

- Geofabric - a woven fabric made of synthetic threads with different weaving methods. By changing the thickness of the threads and their density, materials that differ in physical properties are obtained. Woven geotextile always has a high tensile strength, therefore it is used where there may be mechanical loads - as a reinforcing, separating material. In some types of geo-fabric, the distance between the threads is rather large, which makes it easy to conduct water, while at the same time preventing mixing of materials. These grades are ideal for drainage and can be used as a fraction separator.

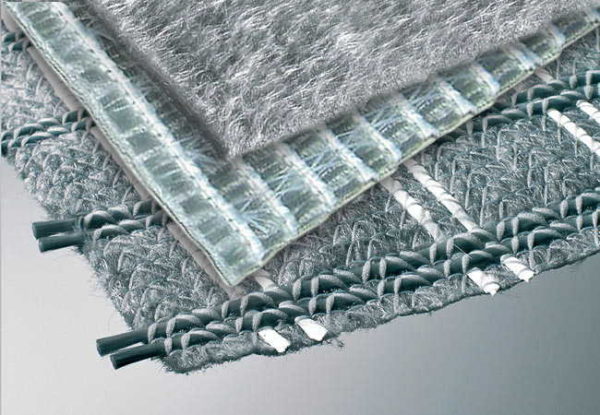

- Non-woven fabric - made of short or long polyester or polypropylene fibers joined in various ways. The connection method can be:

- with needles, geotextiles are called needle-punched;

- when sintering from high temperature - thermally bonded;

- using thin streams of water - hydro-bonded.

- Knitted geotextile (knitting and stitching). This type of geosynthetics is produced only in Russia. Like any jersey, it is not as strong as fabric, and its cost is higher than that of woven and non-woven types. Therefore, it is not very popular and cannot be used in places with high mechanical stress.

If the fibers are connected with needles or thin streams of water, the material looks like felt in appearance, has a fleecy surface. Thermally bonded - smoother. Different ways of connecting threads give different properties to geotextiles, therefore, they are used in different fields.

If we compare all three types of non-woven geotextiles, the highest tensile strength is hydro-bonded, then thermally bonded and the “weakest” - needle-punched (needles still damage the fibers). Thermally bonded geotextiles are made from polypropylene, since polyester has a too high melting point, which dramatically increases its cost.

Impregnation and clanning

There are geotextiles with impregnations - latex, plasticizers, plastic compounds. They give the material additional properties, but almost completely deprive the filtering ability. This must be taken into account when choosing a material. For example, for a pond device, the lack of filtering capacity is a plus, for drainage - a minus.

Clandering - re-bonding of an already finished web. The re-bonding method is usually different from the primary one. This gives the geotextile increased strength.

Application

Geotextiles have appeared recently, but are already used in various fields: in construction, landscaping, horticulture and gardening, in the construction of footpaths, roads and runways. Hygiene products, disposable medical clothing and underwear are made of the same material, only of low density, and used as rough upholstery for upholstered furniture. In general, the field of application of geotextiles is very wide, and it is worth knowing which type is suitable for what purposes.

Depending on the density

The cost of geotextiles can vary significantly. As you already understood, the price is formed depending on the material and method of production. But density also plays an important role. The same materials, but with different densities, have different prices. How do you know which geotextile is needed in a particular case? You can roughly navigate by this division by density:

- Up to 60-80 g / m2 - agrotextile or covering material. Can be used to protect against germination of weeds (geotextiles against weeds). Non-woven polyester is usually used. To avoid confusion, they usually write this way - agrotextile.

- Density about 100 g / m² - for drainage, but geotextile is undesirable, as it quickly "silts up".

- 150 g / m² and above - for separation of fractions: sand and gravel. You can take more dense, but less - not worth it.

- Geotextiles with a weight of 100 to 200 g / m2 are used for the construction of pedestrian paths, under paving slabs, under lawns, to create alpine slides etc.

- With a density of 200 to 300 g / m², they are placed under general purpose roads, under car parking area.

- Above 300 g / m² - for motorways, runways, etc.

These are only approximate boundaries. It is always worth choosing geotextiles, paying attention to specific conditions.For example, on hard and rocky ground, elongation at break will be important. The better the material stretches, the less the possibility of tearing when "fitting" irregularities and protrusions.

When choosing geotextiles for construction work and under roads / paths, parking lots, sites, look for a high breaking load (breaking strength). This characteristic can be neglected if you form relief irregularities, but there will be no load on them.

Depending on raw materials and production method

Thermally bonded geotextiles have high tensile strength, but they drain water only in the transverse direction. That is, it can be used in areas with low groundwater levels, in well-drained soils. It is good as a separator of different fractions and materials when constructing sites for pedestriantracks made of various materials, suitable for changing the landscape. But all this is in areas with good drainage. It is not too suitable fordrainage systems - water is not discharged well enough.

Needle-punched is less durable, but water flows in both the longitudinal and transverse directions. It is suitable for laying on heavy soils that do not drain water well - loams, clays. The lack of strength can be compensated for by laying a geogrid underneath - another type of geosynthetics. It will take on the main loads, and geotextiles will not allow fractions to mix. This type can be used in drainage.The optimum density of drainage geotextiles in terms of price / quality ratio is 200 g / m².

Geotextile for drainage. Properties: elasticity and strength, resistance to heavy loads and mold, high shelf life, ease of installation, fire safety and non-toxicity, resistance to ultraviolet rays

Woven geotextiles are very durable and have high tensile strength. It is ideal for embankments, landscaping, retaining walls. Moreover, it can withstand the load without question. It is not recommended to use it in drainage - the gaps between the threads are quickly clogged with small particles, which impairs water drainage.

Examples of using

The field of application of geotextiles is wide, the following types are divided by purpose:

- Furniture... Not too dense material that is used for upholstered furniture mattress upholstery. Placed under the upholstery fabric, used to protect against dust during transportation.

- Drainage... It passes water well, due to its special structure it is not clogged with sand, silt, retains a high filtering capacity for a long time.

- Garden or agrofiber... The main difference is light-stable, that is, it does not react to ultraviolet light.

- Packing... A thin material from which covers are sewn for packaging (for example, for shoes).

- Building... There are many different materials in this group with different characteristics. The main ones are tensile strength and tensile strength.

When buying geotextiles, pay attention to the technical characteristics and purpose, and do not choose based on price alone. If you put packing, garden or furniture under the rubble, it will do nothing. The money will be wasted, as the material will tear over the course of months, and maybe even during backfill.

Construction

One of the main functions of geotextiles is to separate different layers. These can be different factions, different materials.

- When constructing a foundation of any type, a gravel-sand cushion is laid on the bottom of the pit. So that gravel and sand do not mix and perform their functions, geotextiles are laid between them. Its density is 160-180 g / m², but it can be more / less depending on specific conditions.

- To the bottom of the pit when constructing roads, droshky, platforms for cars, playgrounds, lawns crushed stone is laid. So that it does not mix with the soil, geotextiles are also placed under the rubble.The density is selected depending on the purpose of the object and the planned load. You also need to look at how important water diversion is.

- For water diversion at sites install drainage pipes. They have small holes through which water seeps in, then enters the wells. To prevent the holes in the pipes from clogging, they are wrapped with geotextile membranes. For better filtration, the drain pipes can be sprinkled with gravel. Geotextiles are also used so that it does not mix with the soil.

For all types of work, so that the materials do not "creep" and do not mix, it is necessary to take the width of the geotextile so that it rises to the entire thickness of the layer of bulk material and is still wrapped by 30-60 cm. doing more will be more reliable. This applies to both construction work and landscape, gardening, etc.

In the arrangement of the site

Work on the site involves a large amount of land work. For the results to please for a long time, geotextiles are used.

- When forming flower beds and beds, fertile soil is often imported. So that it does not mix with the "native" soil, the layers are separated with this material. It will also prevent plant roots from growing from below.

- When forming hills, hills, to keep the shape, soil layers are laid with geotextiles.

- When creating artificial reservoirs, geotextile is placed on the bottom. It is more durable, it will be better to reinforce the pit.

- Separation of different materials when creating rockeries, rock gardens, etc.

- The gaps between the beds can be covered with geosynthetics, pouring gravel on top. So the view is solid, and clean, and the weeds do not germinate. When redeveloping, the geotextile is lifted, stones are removed. You can start further work.

- For shelter from the sun, protection from frost, instead of mulch, agrotextile is laid on flower beds and beds, which is the least dense geotextile.

This is only a part of the processes in which this material can be used. There is also a rare use in our country - when creating green roofs.

Laying rules

In order for the geotextile to perform its functions, it must be properly laid. First, let's tell you what shouldn't be. First of all, do not lay geotextiles with holes (mechanical damage). If it is not possible to replace the whole piece, place a patch that is 50 cm larger than the gap. Secondly, it cannot be dragged along. Thirdly, it is prohibited to drive cars on the sent out track.

Further - the general rules for laying geotextiles:

- Spread out on a site previously cleared of stones, roots, construction debris. It is advisable to level the soil and, if necessary, compact. The presence of sharp protrusions or depressions is an additional risk of getting a rupture in this place.

- If several strips are stacked, an overlap is required. The minimum - 30 cm - is done when arranging lawns, pedestrian paths. When laying under roads, platforms for transport, etc., the minimum overlap is 50 cm.

- It is better to fasten the edges of adjacent strips. You can - sew, you can use scotch tape. This will ensure that the edges will not wrap.

As mentioned earlier, the width of the canvas should be larger enough to be able to wrap it on a layer of rubble, earth, sand. And so that the "turn" was at least 30-50 cm.

There is one more question: which side is the correct way to lay geotextiles. There is no definite answer, as it depends on the material. Some types can be installed on either side, while others can only be installed with the smooth side or only with the fleecy side up. Specifically, which side to lay the geotextile is stated in the instructions for the material.If you buy not a whole roll, but only a part, check with the seller for the rules of its laying.

And what density is needed for geotextiles to separate soil layers?