Which is better to build a house

Today, there are more than 20 technologies used to build private houses. It is impossible to say unequivocally that this technology is the best during construction, and this one is absolutely bad. They are all imperfect, they all have positive and negative points. To correctly answer the question "What to build a house", you need to decide on the basic requirements that you have for housing. Choose technology for them. The definition of the best home is different for everyone, material and technology too.

Thinking about which house to build, first of all you pay attention to the cost

The content of the article

What houses are built from

All external walls can be divided into two large groups: inertial and non-inertial. Inertial houses are built from materials with high heat capacity. They tend to accumulate heat, and then emit it. Moreover, the radiation is in the infrared range. In such houses, even with a relatively low air temperature, it is warm. Infrared heat is absorbed better by our body.

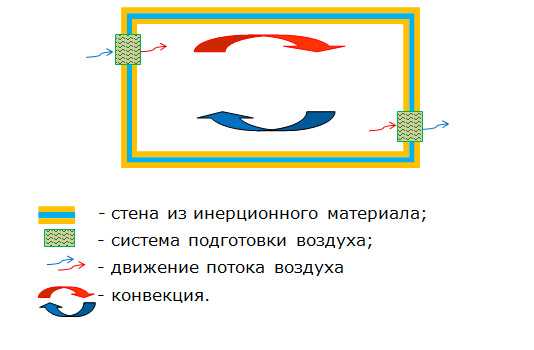

The walls of non-inertial houses are a “cake” of materials of different composition and sequence. But they all have one property: the materials are distinguished by good or excellent thermal insulation properties, but they have low heat capacity. The main difference between houses of this type is that it is not the walls that heat up, but the air and it warms up quickly, but it also cools down the same way. In order to keep the heat for a long time, the premises are made airtight. And this has its drawbacks. Let's talk about the properties of materials in more detail.

Inertial materials

The material of the walls of such houses tends to accumulate heat and remove moisture. To keep the accumulated heat for as long as possible, external insulation is mandatory for them. The advantage of rooms made of these materials is that in the absence of heating, they "hold" the temperature for quite a long time. It follows that such technologies are more appropriate for permanent residences. For a temporary visit, for example, a summer residence, they are inconvenient. It will take a long time to warm up the walls, and if they are cold, the rooms are chilly.

In inertial houses, the walls heat up for a long time, but then they also transfer the accumulated heat for a long time.

Materials for the construction of inertial houses:

- ceramic bricks (solid and hollow);

- adobe;

- ceramic blocks;

- foam block and monolith from it;

- gas block;

- expanded clay concrete blocks and monolith;

- adobe houses;

- cinder block.

The main disadvantage of houses of this type is the rather high cost and duration of construction. Somewhere these shortcomings appear more, somewhere less, but, in general, they are: a powerful foundation is required, the walls take a long time to fold.

Inertia-free materials

Non-inertia houses are built from materials with low energy consumption. These are mainly modern materials and technologies that provide for a multi-layer cake for the walls. The main point is that almost all of them have low vapor permeability or do not conduct vapor at all. The same is with air, it does not pass through the walls. This means that in order to regulate humidity and ensure the flow of fresh air, remove carbon dioxide, a competent ventilation system in the house is necessary.

The main requirement for non-inertia houses is compliance with the technology and the tightness of the room, and ventilation is necessary to regulate the air conditions

Inertia-free houses are built from the following materials:

- 3 Dpanel, MDM, SOTA - there is expanded polystyrene inside the system, and densely reinforced concrete outside;

- Termodom, Izodom - concrete is poured into the fixed formwork from expanded polystyrene;

- polystyrene concrete - a new type of material - concrete with polystyrene filler;

- sandwich panels - more often they build industrial facilities from them, but sometimes, in order to save money, they build country houses;

- SIP panels - insulation (mineral wool or polystyrene) between two OSB boards;

- frame houses - insulation between plywood or OSB slabs:

- vacuum panels are a new construction technology that has not yet been used in private housing construction, but already exists.

The main advantage of non-inertial houses is short terms and low construction costs. Since the walls are light, the foundations for such structures are required inexpensive. They account for a significant part of construction costs, then the overall reduction in construction costs is significant. If you are deciding which house to build and the key constraint is money and / or time to build it, you may need to choose from these materials. But at the same time, one should not forget about the device of ventilation systems and be sure to take into account its cost when calculating. Otherwise, life will be very uncomfortable, and in some cases impossible.

This is a diagram that sellers of new technologies demonstrate their advantages, "forgetting" to talk about the disadvantages

Wooden houses

Wooden houses stand apart. These are houses made of logs or beams (ordinary, profiled, glued). On the one hand, the walls breathe, on the other, their inertia is small. Previously, such structures could be attributed to partly inertial due to the fact that in the center of the building there was a furnace with a high heat capacity. The heat accumulated in it warmed the house until the fire burned.

When building wooden houses today, few people install a brick oven for heating. This is mainly water heating. Therefore, they can be classified as non-inertial. If a large-diameter log still has at least some significant inertia, then the heat stored in the 150 * 150 mm bar is definitely not enough. It is necessary either to throw up fuel at night, or to install combined boilers that run on electricity at night. There is another way out - to do external insulation. The measure is understandable and quite effective, but only if the insulation and finishing material are vapor permeable.

Without proper care, a wooden house will look like this

Another important aspect is that in order for wooden houses to look normal, they need annual maintenance. This means that every year or every two years (depending on the type of treatment) you will have to either work with a brush yourself or hire workers. Without this, a beautiful building will turn into black and unattractive. Actually, then there is a way out - to make an exterior finish, and this is also a cost, as well as wood maintenance - impregnation, paints cost a lot.

As you can see, there really are no ideal technologies. To build a house correctly, you need to proceed from your environment. Decide on the key points that will allow you, with awareness of all the nuances, to choose the material for the walls and the technology for its construction. Let's take a closer look at a few of the most common house requirements. Read about the features of the construction of wooden houses from a bar in this article.

Which house is cheaper to build

Let's start with the fact that the cost of building the foundation and box of a house made of all industrial inertial materials is definitely more expensive than non-inertial ones. They have a high density, and this is reflected in the mass of the building, which leads to an increase in the cost of the foundation.

The most expensive house is brick. We will take it as a standard and the cost of construction using other technologies will be compared with it. The next in cost is made of ceramic blocks, about 90% of the price of brick. The most inexpensive of this group are adobe and adobe houses.

The adobe house is 100% eco-friendly, warm, cheap

If you have time and weather permits, during the summer you can make and dry adobe bricks on a very large house. In terms of the cost of materials, they can compete with many modern technologies. Especially if you can extract the clay yourself. The rest of the fillers - straw, manure, etc., are free or cost a little. The only thing is that it takes time to make a brick, and it is sometimes more expensive than money. After all, they are not manufactured industrially. Another limitation of the climate, not all weather will allow you to dry clay to a stone density. So this technology is available for budget construction in regions with hot summers.

More expensive than adobe, but decently cheaper than brick, block buildings. Aerated concrete, expanded clay concrete and foam concrete blocks require approximately 70-75% of the estimate for the construction of a brick house. But aerated concrete requires excellent waterproofing and it is risky to use it in areas with high groundwater levels. Slag concrete is inexpensive. By the way, you can do it yourself. But the service life of slag concrete is about 50 years. Further, it will collapse. Read about building a house from aerated concrete here.

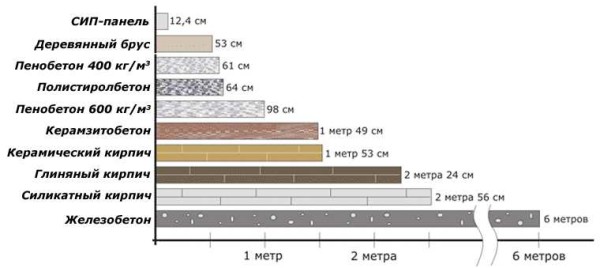

Even less, about 30-50% of the cost of a brick house is required for the construction of non-inertial houses. The cheapest house made of SIP panels. They spend no more than a third of the price of brick construction. Frameworks will require about 40%. But at the same time, the service life is about 25-50 years, depending on the quality of materials and the accuracy of technology compliance. However, for this whole group, compliance with technology is key, even small deviations can have dire consequences.

In addition to building a house on a wooden frame and about houses on a metal frame in this article.

The least cost is a box of SIP panels

Once again, we draw your attention to the fact that the cost of the ventilation system must be added to the cost of all non-inertial boxes. If it comes out natural, but not, then it will be necessary to establish a forced one. It is much more expensive to set up and maintain. But ventilation must be, and it must be calculated correctly.

The construction of a wooden house will require about 60-70% of the cost of a brick one. But here it is also necessary to include caulking and polishing the log house. You cannot do without them. Although, if a wooden house is immediately planned for finishing, polishing is not required.

What is faster to build from

The longest construction period for a brick house. It will take at least a year to build it. That is, if all technical processes go without delay. It will take about 6 months to distill the box from the building blocks from the finished adobe. It is possible to build a house from all types of panels for 1-3 months. The same amount will be required for the assembly of frame houses.

Wooden houses do not fit into any group. If you cut the corners in place, it will take about a month or two to assemble the walls. If you ordered a finished project and a layout with cut bowls was brought to the site, you can fold it in a few days. Add time for foundation and roofing. As a result, it will turn out up to six months. But you will not be able to enter immediately after the forcing of the walls; you need to wait at least another six months or even a year before finishing finishing. Depends on the original importance of the material.

The longest time to build a brick house

Only a house made of laminated veneer lumber can be finished immediately. All other wooden houses must withstand at least six months. The wood should dry out, shrink and take on its operational dimensions. The difference in height can be up to 15–20 cm per log house, which is a lot. Therefore, finishing begins only after 9-12 months. So put the box and quickly move into it in this case will not work.

So, the features of the sea. But if you are deciding what to build a house in the country, and you plan to stay there only during the season and there is no desire to spend a lot of money, then pay attention to frame houses or SIP panels. They are both inexpensive and quick to build.Just study the technology thoroughly, they don't like mistakes.

My home is my castle

The fortress of the walls, in brick houses in the first place. These are exactly bullet-proof walls and quite strong: expanded clay concrete, cinder block, adobe technologies. With other building blocks, it is a little more difficult to look at density.

Expanded clay concrete is a good choice - quite dense to be reliable, average in price and in construction speed

Houses with concrete components 3 Dpanel, MDM, SOTA, Termodom, Izodom turn out to be quite strong. All other technologies are in no way an obstacle to serious shock loads.

As you can see, it's definitely not possible to say that some technology is the best. Weigh the advantages and disadvantages, choose the most important points and determine personally for yourself which house to build so that it meets your requirements.

Thanks for the useful information!

Millions of people dream of owning a home.

And they don't just want to buy a box of windows,

and completely and completely do everything ourselves -

from the project to the flowers in the flowerbed.

And this is natural, because your home is a family hearth,

a place to meet friends and family, a place,

where children will grow up and grandchildren will play