Where and when you can use Penoplex, its technical characteristics

The choice of insulation is not an easy task. Some of them are afraid of getting wet (stone wool), others are difficult to work with (glass wool), and others have not yet found widespread use (foamed glass). There remains polystyrene foam. He is scolded for unnaturalness and flammability, but according to technical characteristics, he is among the leaders. Moreover, extruded polystyrene foam (EPS), although it is more expensive, tolerates mechanical stress better than ordinary foam. One of the manufacturers, Penoplex, produces EPS of various densities and purposes. Its products are quite popular - it is one of the most famous brands in the country.

The content of the article

What is Penoplex and its scope

Penoplex (sometimes written "Penoplex") is a thermal insulation material produced by the company of the same name.

The PENOPLEX company is a large Russian manufacturer of construction and decorative finishing materials based on polymers. The company began its activity in 1998 with the launch of the first production line in Russia for the production of heat-insulating materials from extruded polystyrene foam under the PENOPLEX® trademark.

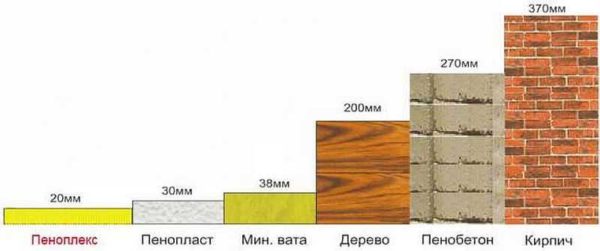

The PENOPLEKS company produces extruded polystyrene foam (EPS or XPS). This material is used as insulation. It differs from the cheaper analogue - expanded polystyrene (polystyrene, PPS or PPS) - with a higher density, due to which it better tolerates mechanical loads. Another distinctive feature is lower vapor permeability. Rather, it hardly conducts steam. And the main trump card is the best thermal performance. Penoplex 20 mm thick in terms of heat retention is equivalent to almost twice the thickness of mineral wool and 37-centimeter brickwork.

These characteristics determine the area of use of Penoplex. It is recommended for insulating those areas where resistance to stress is important, and low vapor permeability is one of the requirements. More specifically, it is recommended to use Penoplex:

- For floor insulation:

- under the screed, on it, as an intermediate layer;

- when installing the floor on logs (with some reservations);

- heat-insulating layer under the warm floor (water or electric).

- Whenarrangement of blind areas around the house.

- Insulation of the basement of the house (if it is uninhabited).

- On roofs (ideal for flat roofs, green roofs, with the rest you need to be careful because it almost does not remove steam).

- Paths, platforms for gazebos.

- Insulation of septic tanks, wells, etc.

Another area of use is thermal insulation of facades or interior walls. But here you need to understand that due to the fact that Penoplex practically does not conduct moisture, additional measures will be needed to prevent vapors from getting inside the wall. Plus, a well-thought-out ventilation system is needed to normalize humidity in the house. And, in addition, you need to choose the thickness of the insulation so that the dew point is inside the insulation, but not in the wall.

If you prefer "breathing" walls, natural regulation of humidity - for this case Penoplex is not suitable for wall insulation. It does not go under ventilated facades either. There, just the task is to remove moisture from the insulation due to the movement of air in the ventilation gap. This material is not able to provide, since moisture, simply, does not get inside Penoplex.

Types, characteristics, properties

Penoplex is produced in several categories:

- Comfort. For insulation of walls, balconies, loggias.

- Foundation.

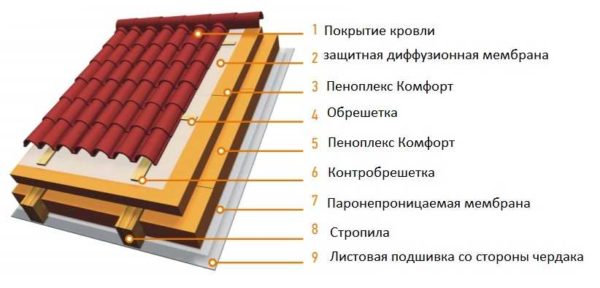

- Pitched roof.

- Wall.

As you can see, the manufacturer clearly delineates the areas of application of the material. With the general technology, they differ in density. The most dense ones are for the foundation and floor, since they must withstand considerable loads for a long time. The manufacturer claims that the service life of Penoplex Foundation is up to 50 years.

Design differences

Some of the Penoplex types have structural differences:

- Penoplex Wall slabs have a rough surface, stripes are applied to the surface of the slab by a mill. All this improves adhesion to the wall and / or finishing materials.

- Penoplex Comfort is distinguished by an L-shaped edge, which guarantees the absence of through seams during installation.

- Penoplex The roof has a U-shaped edge, which increases the reliability of the connection.

This is about external differences. Next, let's look at the technical specifications. To begin with, let's pay attention to the common to all species, then to what distinguishes them.

General characteristics

Since the production technology of all Penoplex types is similar, they have many of the same characteristics:

- Water absorption is very low:

- when immersed in water for a day, no more than 0.4% of the volume;

- when immersed for 28 days 0.5% of the volume.

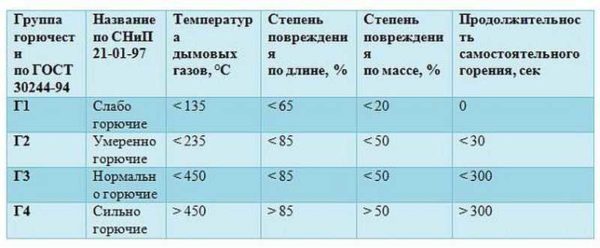

- Fire resistance - G4. The material burns, therefore it should not be used in places where there is a danger of heating above 80 ° C.

- Thermal conductivity coefficient 0.032 W / (m × ° K). This is 9 times lower than that of Rockwool mineral wool mats (0.30 (m × ° K)), which is considered one of the best in its group.

- Specific heat capacity is 1.45 kJ / (kg. ° C). Low heat capacity - little time is required for heating after, for example, freezing.

- Sound insulation of the partition (GKL-PENOPLEKS® 50 mm-GKL) - 41 dB. EPPU is not a very good sound insulator. Most of this bundle falls on the GCR.

- When used in floor construction, structure-borne sound insulation is 23 dB. When installing EPPS on the floor of sufficient thickness, the sounds (including percussion) will become less clear.

- Water vapor permeability - 0.005 mg / (m.h. Pa). Water vapor permeability is very low. That is, moisture almost does not pass through it in a vaporous state.

- Temperature range -70 ° C to + 70 ° C.

As you can see, in terms of temperature indicators, any type of Penoplex can be used in any part of the country - from the south to the north. Moreover, if it is left to "winter" in an unprotected form, nothing will happen to the material. This is not the merit of Penoplex, but the general property of extruded polystyrene foam.

What distinguishes different types

The manufacturer divided the Penoplex types into areas of use. Their properties are optimal for a specific application. For example, the increased density of EPS, required under the screed, will not be needed when it is installed on the base. Taking into account the fact that the price differs significantly, it makes no sense to use the "Foundation" brand for other purposes. But the difference in locks, all other things being equal, can be neglected. Here we are talking about ease of installation. Although, this is also important.

| Parameter | Comfort | Foundation | Roof | Wall |

|---|---|---|---|---|

| Density | from 20 kg / m3 | 27-35 kg / m3 | 26-34 kg / m3 | from 20 kg / m3 |

| Elastic modulus | 15 MPa | 17 MPa | 17 MPa | 15 MPa |

| Thickness | 20, 30, 40, 50, 100 mm | 50, 100 mm | 100 mm | 50 mm |

| Static bending strength | 0.25 MPa | 0.4 MPa | 0.4 MPa | 0.25 MPa |

As can be seen from the table, Penoplex for the foundation and roof is denser, stronger, and better withstands bending loads. Designed for walls and the "Comfort" brand are less durable, since their area of application does not require resistance to mechanical stress.

Low vapor permeability - good or evil?

As you know, the same material property in one situation can be considered a plus, in another - as a minus.This is exactly the case with the low conductivity of steam, which is distinguished by extruded polystyrene foam. Moreover, he does not conduct steam in either direction. Moisture does not penetrate from one side or the other. This is what distinguishes it from vapor barrier membranes, which can have one-sided conductivity.

Where vapor non-conduction is needed

With proper installation (without gaps and cracks) with gluing joints, EPPS does not require the use of vapor barrier membranes. He hardly misses steam. Neither liquid nor gaseous. So the use of membranes and waterproofing is unnecessary. When used in a floor cake, this is great, because the moisture usually comes from the ground. When using expanded polystyrene, it does not penetrate either by capillary method or in the form of steam. In this case, this is definitely a plus.

These properties also play "plus" when using extruded polystyrene foam in the blind area, under tracks, etc. Besides the fact that it protects against freezing, it does not get wet. This allows, with a competent approach, to get rid of frost heaving and make, for example, not a deep strip foundation, but a shallow tape or a Swedish slab.

The use of EPS in a flat roofing cake is also optimal - leaks are minimized, heat also hardly escapes. When used on pitched roofs, it's worth thinking about. The fact that Penoplex Roof does not allow moisture to enter the attic is good. But it will be possible to remove excess moisture from the attic only with the help of very good ventilation, which includes not only dormer windows. Additional elements will be needed on the ridge, in the plane of the roof. In general, given the cost of Penoplex, this is not always reasonable.

On the walls: yes or no?

Wall insulation with Penoplex is permissible only if you agree to make an effective ventilation system that will regulate the humidity in the house. In this case, there are two options:

- Insulate the walls with EPSP from the inside. With this solution, moisture practically does not get into the enclosing structures (into the material from which the walls are made) due to the low vapor permeability of the material. In this case, the Penoplex layer for walls can be of a small thickness. Specifically, it must be considered, since it depends on the material and thickness of the walls, the region of residence. But, with such insulation, it is necessary to select the external finish of the facade so that moisture is not trapped inside the wall. Ventilated facades are most suitable for this purpose.

- Stick the EPS on the outside. But at the same time it is necessary to make an effective vapor barrier inside the room. It is needed so that moisture does not get into the walls. Since the EPS is outside, it will not be displayed. So that moisture does not accumulate in the wall, and vapor barrier is required. In this case, the thickness of Penoplex will be large. So large that the dew point is not in the wall, but in the thickness of the insulation. That is, in this case, you will have to insulate the walls of EPSP with a thickness of 100 mm or more.

As you can see, there are options for using extruded polystyrene foam for wall insulation, but they are far from the best. Despite the fact that the material itself is good, it is not suitable for this purpose.

And we must also take into account that the second option is only for non-hygroscopic materials. Such a scheme is very undesirable for wooden, frame buildings, it is poorly suited for a foam block. The fact is that no matter how good the vapor barrier is, some of the moisture will still get into the walls. If the material is not hygroscopic, moisture will gradually be removed from the wall during the dry season. This process is more complicated with hygroscopic materials. As a result, the tree rots, the foam block walls "bloom".

Dimensions and weight, quantity calculation

Penoflex thermal insulation boards can be of different thicknesses, so the package can have different sizes, it can have a different number of sheets. It should also be noted that the dimensions of the slabs are indicated without taking into account the spikes / locks.

| Name and thickness | Dimensions (L / W) | Amount in a package | Insulation area per package | Packing volume |

|---|---|---|---|---|

| Comfort 20 mm | 585 * 1185 mm | 18 pcs | 12.48 m2 | 0.273 m3 |

| Comfort 30 mm | 585 * 1185 mm | 12 pcs | 8.32 m2 | 0.2704 m3 |

| Comfort 40 mm | 585 * 1185 mm | 9 pcs | 6.24 m2 | 0.2493 m3 |

| Comfort 50 mm | 585 * 1185 mm | 7 pcs | 7.69 m2 | 0.2429 m3 |

| Comfort 100 mm | 585 * 1185 mm | 4 things | 2.77 m2 | 0.2772 m3 |

| Foundation 50 mm | 585 * 1185 mm | 7 pcs | 7.69 m2 | 0.2429 m3 |

| Foundation 100 mm | 585 * 1185 mm | 4 things | 2.77 m2 | 0.2772 m3 |

| Pitched roof 100 mm | 585 * 1185 mm | 4 things | 2.77 m2 | 0.2772 m3 |

| Wall 50 mm | 585 * 1185 mm | 8 pcs | 5.55 m2 | 0.2776 m3 |

There are two methods for calculating the number of packages, using the volume or area of the package:

- You know the area to be insulated, find the area of the insulation of the required thickness in the package and divide the area to be insulated by this value. For example, 15 squares need to be insulated, 40 mm thick plates will be used. Insulation area in a package - 6.24 m². We consider: 15 / 6.24 = 2.4 packages.

- To calculate by volume, we multiply the area to be insulated by the thickness, we get the required volume. Further, by analogy with the example above, we divide the found figure by the volume of one package. We get the number of packages of insulation. Let's calculate for the same case: 15 m² * 0.04 m = 0.6 m³. According to the table, one package of this material has a volume of 0.2493 m³. we find the number of packages: 0.6 / 0.2493 = 2.4 packages.

If the number of packages is not whole (most likely it will), some surplus is formed. If the surplus turns out to be large (as in the example - more than half of the plates is unnecessary) and you will have nowhere to use it, check if the seller is selling incomplete packages. In this case, the calculation will be a little more complicated. You should estimate how many plates you need in addition to the whole packages. For this:

- Find the area covered by whole packages. For example, this is: 2 pack * 6.24 m² = 12.48 m².

- Since we need to insulate 15 squares, we subtract the found from this figure: 15 m² - 12.48 m² = 2.52 m². This is the area for which additional slabs should be purchased.

- The area of one Penoflex insulation board is 0.6932 m². If the remainder is divided by this figure, we get the required number of additional sheets of insulation: 2.52 m² / 0.6932 m² = 3.63 pcs. It turns out that we will need 4 plates in addition to two packs.

With such an accurate calculation, it is better to take a small margin - one or two plates. In case if somewhere there was a mistake in measurements or calculations, somewhere the edges were jammed and other unforeseen cases.

Installation technology

When laying on horizontal surfaces - floor, flat roof - the slabs are simply laid on a flat surface. The surface should be free of sharp drops, the maximum deviation is 2-3%. This requirement must be met so that voids do not form. When laying, we follow the connections, it is advisable to glue them (you can use adhesive tape) or fill them with the same foam / glue on which the plates are attached.

If two layers of thermal insulation are applied, it is positioned so that the EPS boards of the second row overlap the seams of the lower one. They also say that the slabs are laid with alternating seams or "staggered".

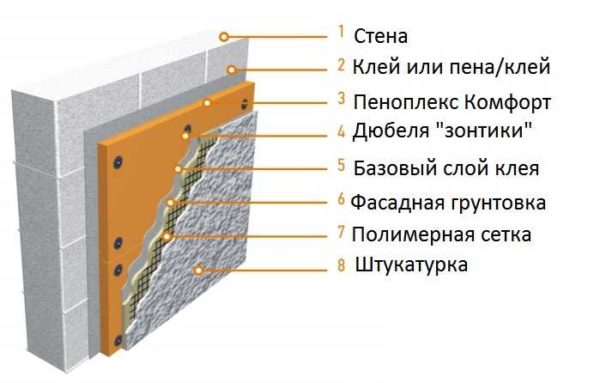

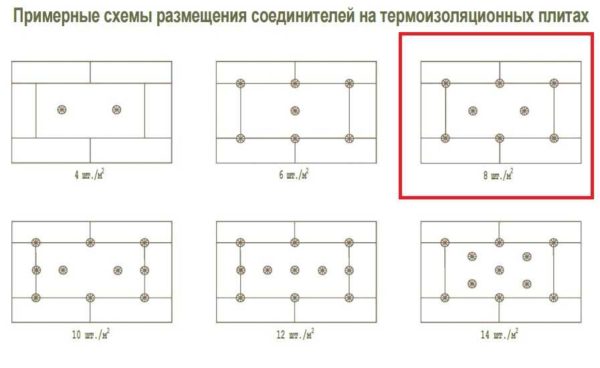

When mounting on vertical surfaces, double fixing is used:

- Glue or foam glue is applied to the plane.

- They are additionally fixed with umbrella dowels.

According to the technology of installing slab insulation on facades, umbrella-dowels are installed at the junction of two sheets (any two sheets) and in the plane of the sheet - two more additional fasteners. That is, there are at least 8 fasteners per sheet (marked in red in the figure). More is possible. Less is not. Unless, of course, you want the finished insulation to come off. If the winds in the region are strong, it is better to put more. For insulation inside, you can put less (see the diagrams below).

During installation, on extreme plates and around openings, we install fasteners more often: three to four elements per plate. To keep the insulation rigid in the corners of the openings, a mesh is attached to it before plastering. It is attached at an angle of about 45 °, holding the joint together. Under such conditions, there will be no problems with finishing inside or outside.

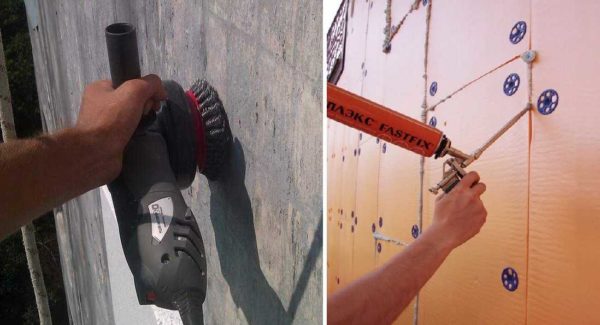

If plaster, facade tiles, finishing stone and other heavy materials are subsequently applied to Penoplex, before starting installation, care must be taken to improve the adhesion of the material to the wall and to the finish. Even if you are installing Penoplex Wall with stripes, it is better to add roughness to the plate with a metal brush. And from two sides. If the wall is smooth, it also does not bother to add roughness - for better adhesion.

For working with Penoplex, a special adhesive mixture is recommended: Ceresit CT 84, illbruck PU 010, Titanium 753, Ceresit CT-85, Kreisel 210 and 220, Baumit ProContact, STO Baukleber, Soudal Soudabond, Penosil Fix and Go, Den Braven, Krass.

Good day!

Can you please tell me what is the best way to insulate a metal shed in the country (floor, walls, roof)? Region - the south of the Rostov region, in winter frosts down to -20, in summer heat up to +40, ground waters are close to the site.