Cement particle boards (DSP): properties, dimensions, application

Sheet building materials are used in many types of construction work, which are commonly referred to as "dry". One of these materials is DSP board. It is a durable material that can be used in the construction of frame houses and outbuildings, for interior and exterior finishing work.

The content of the article

What is DSP board

Cement particle board (DSP) is a foliage building material that is made from high quality cement (Portland cement) mixed with thin long wood chips (according to GOST 26816 chip thickness 0.2-0.3 mm, length from 10 mm to 30 mm) ... Aluminum sulfate and water glass are added to the composition. When mixing, water is added (about 8% of the total mass). The resulting substance is formed into plates and pressed.

Some manufacturers make DSP boards from several layers. They separately mix compositions with smaller and larger chips. A mixture with coarse chips is used for the inner layers, giving greater strength. From the composition with finer chips, outer layers are formed, which makes its surface smoother. The folded "pie" enters the press, as a result a monolithic DSP slab with improved characteristics is formed.

It should also be said that there are polished and unpolished DSP boards. Sanded can be used for interior or exterior decoration in those works, after which finishing works can immediately follow. There are also finishing boards of DSP, on one of the surfaces of which a finishing layer is formed in the form of stone or brickwork, decorative plaster, etc.

Application area

DSP is mainly used in dry mounting technologies. They are good in the construction of frame houses, as they do not emit harmful substances, have high strength, are low-combustible, emit a small amount of smoke during a fire, and do not spread fire. Having high mechanical strength, they increase the rigidity of frame structures. All this makes the frame houses, sheathed with DSP, safer and more reliable.

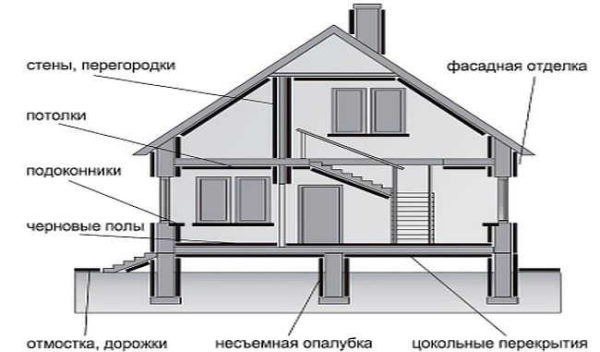

Objects for using DSP

Sheet DSP can be used in the construction of the following objects:

- Frame residential buildings up to 3 floors inclusive.

- Industrial, office buildings.

- Hotel complexes.

- Kindergartens, schools.

- Medical institutions.

- Sport halls.

- Warehouses, hangars.

Disadvantage: DSP slab has a significant mass (several times heavier OSB), which increases the requirements for the foundation. Solid weight also becomes a problem when climbing to the second floor - helpers are needed andforests or lifting equipment (at least a winch). Another disadvantage of DSP is its low resistance to bending loads. This limits the scope of their application - they are placed on the base, in places with low bending load, or must be mounted vertically.

Resistance to weathering and high humidity, fungi and bacterial lesions, allows the use of cement-bonded particle sheets in the construction of outbuildings: sheds, outdoor toilets, garages, cellars.

For interior and exterior finishing works

Another area of application of cement particle boards is floor and wall leveling. Compared to other materials, the DSP board has better sound insulation characteristics, is not susceptible to fungal attack, and tolerates climatic influences well. Therefore, they are often used when creating ventilated facades.

For interior decoration, DSP boards can be used for the following works:

- Soundproof and fireproof partitions and walls.

- Internal facing of premises for any purpose (residential and non-residential, including those with high humidity).

- Window sills.

- Rough floor.

- Ceilings.

The good news is that there are cement-bonded particle boards, sanded and unpolished. Sanded have an absolutely smooth surface. When using them, you can only close up the seams and then paint, glue wallpaper, use other finishing methods.

Characteristics and properties

DSP board is a relatively new material that is not yet widely used in private construction. This is because not everyone can imagine how he behaves in the long run. To understand whether it is good or not for your purposes, you need to know about all the properties.

Density and mass

Density of CBPB is 1100-1400 kg / m³. The high density gives the frame structures an increased level of rigidity. If this material is used for interior decoration, such walls have sufficient load-bearing capacity to support shelves, cabinets and other sufficiently heavy objects.

The material is quite dense and heavy. One sheet with a height of 2700 mm - depending on the thickness - weighs from 37 kg to 164 kg. This makes cladding on the second floor and higher inconvenient. This can be considered a disadvantage.

Thermal and humidity expansion

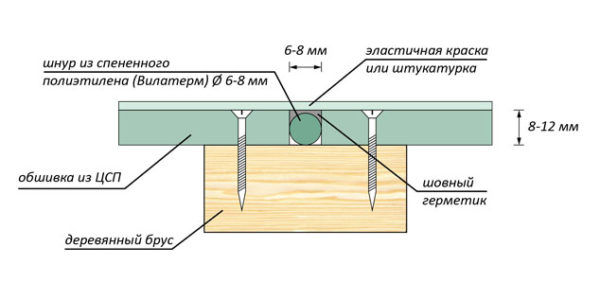

For construction, such a characteristic as linear expansion with changes in humidity and temperature is still important. For a DSP slab, it is present, but it is small. When placing the plates one next to another, it is recommended to leave a gap of 2-3 mm between them. When installing the second row (in height), the recommended gap is 8-10 mm.

- Normal moisture content when sold is 9% (± 3%).

- Low water absorption allows this type of material to be used for outdoor decoration, for wall cladding in a room with high humidity. When in water for 24 hours, the limit for the increase in thickness is no more than 1.5%. That is, when wet, they hardly change their size.

What else is worth knowing: when immersed in water, the dimensions change slightly - 2% in thickness and 3% in length. If the material is made according to the technology, then even with a long stay outdoors in the open air, it does not change for years.

Strength indicators and installation features

Cement particle boards do not tolerate bending deformations well, but have very high strength under longitudinal loads. Therefore, they are used for mounting on vertical surfaces. Manufacturers do not recommend placing them on logs, but when laying on a rough floor or a rough screed, the material behaves stably. Since the DSP board is not afraid of water ingress, it can be laid on the floor in rooms with high humidity.

Elastic modulus:

- under compression and bending 2500 MPa;

- tensile - 3000 MPa;

- with shear - 1200 MPa.

If the DSP is mounted on a frame, a lathing with a pitch of at least 60 cm is required. During installation, fasteners are installed in 20 cm increments. We install self-tapping screws not only along the perimeter, but also along the intermediate rivers of the lathing. In this case, tiles can be glued to the DSP board (primer, after it dries - non-adhesive composition can be laid tiles).

Fire hazard and frost resistance

DSP board belongs to hardly combustible materials, fire does not spread over the surface, toxic or harmful gases are not emitted during combustion. Fire resistance limit (ability to hold back fire) - 50 minutes.This means that the material will disintegrate after 50 minutes in the fire.

High frost resistance - the decrease in strength after 50 freeze / thaw cycles is no more than 10%, which makes it possible to use the material for building houses even in the Far North. The service life of this material outdoors is 50 years.

It is these properties that make DSP the preferred material for frame house building... The structure turns out to be more reliable in terms of fire safety.

Soundproofing structures

DSP slab has good sound insulation characteristics and can be used for cladding external or internal walls:

- reducing the level of airborne noise for a slab with a thickness of 10 mm - about 30 dB, for 12 mm - 31 dB;

- a decrease in the level of impact noise with slabs laid on a reinforced concrete floor - with a thickness of 20 mm it is 16 dB, with a thickness of 24 mm - 17 dB;

When using additional intermediate layers, impact noise becomes quieter by another 9-10 dB. That is, frame walls sheathed with DSP slabs retain enough sounds to keep the house quiet.

The best combination is a combination of cement particle board and mineral wool. Mineral wool also serves as a heater, since due to the homogeneity of the cement-bonded particle board, it has a low thermal resistance (it is not a heat-insulating material).

Performance characteristics

CSP boards are characterized by high vapor permeability - 0.03 - 0.23 mg / (m · h · Pa). This is about the same level as that of natural wood. With the correct selection of the wall paneling cake, the humidity in the premises will be regulated naturally.

In addition, the DSP board has a high resistance to decay. This happens due to the natural process of formation of calcium hydroxide, which is formed during the transformation of cement into concrete and alkalizes the material so that it becomes an unfavorable habitat for fungi, insects and putrefactive bacteria.

Dimensions and weight

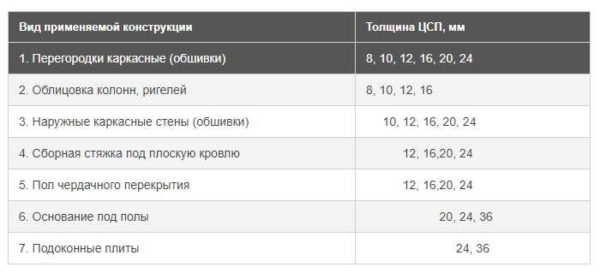

When purchasing materials for construction and finishing works, such characteristics as the size and weight of the material are important. DSP sheets are produced in two sizes: with a width of 1250 mm, the length can be 2700 or 3200 mm. In this case, the thickness of the CBPB boards can be 8, 10, 12, 16, 20, 24, 36 mm.

It is clear that the thicker the slab, the greater its mass. Approximate weight values are given in the table (different manufacturers may have deviations both upward and downward in weight).

You may also need the following parameters:

- area of one sheet:

- 1250 * 2700 - 3.375 m²;

- 1250 * 3200 - 4.0 m²;

- weight of a cubic meter of CBPB - 1300-1400 kg.

DSP sheet is a homogeneous monolithic material without air inclusions, which explains the high thermal conductivity of the material. This must be taken into account when developing the insulation cake. The material adheres well to wood, polymers and metal, so that it is convenient for construction work.

Mounting methods

The DSP board can be fastened with nails or self-tapping screws. When installing on a frame, the plates must be mounted strictly vertical.

For fixing cement-bonded particle boards, you can use:

- Galvanized screw nails from 2.5 mm in diameter. The length is selected depending on the thickness of the sheet and the entire cake. The restrained part of the nail must be at least twice the thickness of the slab, but not less than 10 nail diameters.

- Screw and self-tapping screws with pre-drilled holes for the heads. The length is chosen according to the same principle.

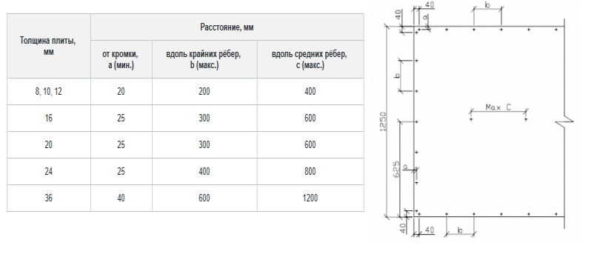

When installing DSP boards, it is necessary to strictly monitor the number and order of installation of fasteners: the material has a large mass, so fasteners must be installed at least the recommended values.The distance between nails or screws depends on the thickness of the board and is indicated in the table.

Each sheet of cement-bonded particle board is fixed around the perimeter, retreating a certain distance from the edge of the sheet. The installation frequency along the long and short side of the sheet is the same, but depends on the thickness of the material. In addition, there is also an intermediate mount - in the middle of the height. Here the frequency of installing screws or nails is half as often as around the perimeter.

Processing and finishing methods

Although cement particle board is much stronger Chipboard, it is processed with the same tools: a milling cutter, a saw, a jigsaw. The difference is that you need to use stronger files.

A hard tipped drill is recommended for drilling. You can use both a hand and an electric drill. It is not recommended to grind this material, since during this work the top layer is removed, which increases water absorption. But when docking, sometimes it becomes necessary to align the height. In this case, any type of grinder can be used. The recommended grit of sandpaper is # 16-25.

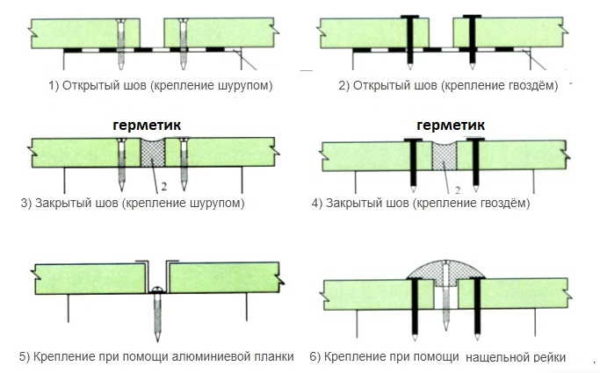

Please note that in order for the seams between the slabs not to crack, the seam must be at least 4 mm with the inner section, and at least 8 mm with the outer one. The distance is large, it can be closed with special slats (usually used for outdoor decoration) or with elastic tape or sealant.

As a finish, the DSP board can be painted or covered with plaster. In outdoor decoration, the joints between the slabs are often simply painted over, leaving them unsealed. Another option is to use an aluminum profile strip that emphasizes the seams. You can also close the seam with a strip strip.

For interior decoration, the seam is filled with a sealant, which, after drying, retains its elasticity. After that, you can plaster. The second option is to lay a special elastic cord, over which elastic plaster is again applied.