We make an attic bed ourselves (2 photo reports + drawings)

Children dream of a bed at a height and for this they agree to put up even with the inconvenience. The second attraction for them is the opportunity to make their own territory below the "house". For parents, this option is attractive by the rational use of the area. The only drawback of the ready-made options is the solid price. An excellent solution is a do-it-yourself loft bed. Firstly, the costs will be small, and secondly, build exactly according to your size.

What's the best thing about loft beds? That both children and adults use them with pleasure. Moreover, children of any age - from toddlers who still go to kindergarten to teenagers. With an adult audience, it's a little more difficult. Young people agree on the loft bed, older people no longer find delights in rest upstairs. Nevertheless, the age spectrum turns out to be solid. All models described below can be used for both children and adolescents and adults. Everything is solved simply - by changing the dimensions.

The content of the article

In a narrow teenager's room, 2.5 meters wide, it was decided to make a loft bed, put a ready-made chest of drawers and a wardrobe with drawers below. Therefore, the attic bed with their own hands was made on one side on support boards, since the bearing capacity of the walls allows it.

Assembling the frame

The ceiling height is large - almost 3 meters, the bed was decided to be made about 2 meters high - so that you could walk normally below. The walls were marked with vertical lines along which the upper edge of the support bars was aligned. These lines should be at the same level and be strictly horizontal. The easiest way to do this is with a laser level (how to use it read here). If it is not there, it will be necessary to level it with water.

On one wall we just nail down a board - there will be a cabinet here, so just a support board fixed on powerful anchor bolts.

Logs will need to be fixed to this board - transverse boards. U-shaped mounting brackets are used for their installation. We nail them to the board with nails in each hole.

The installation step is 50-60 cm, but depends on the thickness of the board that we will use on the flooring. The thinner the board, the more often supports should be placed.

On the opposite wall, we collect the supporting structure, here we assume to make shelves, we collect a frame for them. The top board should be located exactly on the same level with the opposite one.

We fix the boards on dowels (brick wall), reinforce the joints with metal mounting plates, check the verticality and horizontalness of each element. To the upper plank at the same level as opposite, we attach the supports for the flooring joists. They should also be located strictly in the same plane. On the supports we lay the timber cut to size.

In the side surfaces of the plates there are holes for the installation of fasteners. You can use wood screws or nails of a suitable length.

If done correctly, all logs will be horizontal. You also need to check that their top edges are all in the same plane.

Flooring

A dry planed grooved board was used for flooring. It is laid across the log, fastened to self-tapping screws. The length of the self-tapping screw is at least three times the thickness of the board: for a board of 20 mm - at least 60 mm. Fasteners are installed in each log (at least one, but with a wide board, two in each log).

So that there are no gaps between the boards, take a mallet, a small - 50-60 centimeters - piece of the board, insert it into the groove or comb (which you get from the edge) and knock on this piece with a mallet, achieving a tight fit of the board along the entire plane. Then you can fasten.

Staircase construction

From a thick dry board, first cut out two bowstrings - the sidewalls to which the steps will be attached. It is more convenient to climb if there is even a slight slope. To provide it, we cut the ends of the boards at a slight angle. Having installed them in place, we mark the cutout that will fix the bowstrings in the required position.

For a given staircase height, it was decided that seven steps would be normal. Divided the length of the bowstring into eight parts, got the attachment points for the steps. Now at all these points we draw a horizontal line (the bowstrings are in the "working" position).

We fill the steps along this line. On each side, we screw in at least three self-tapping screws one step. Length - also at least three times the thickness of the bowstring board. There is a second option for attaching steps - to the corners. Maybe this will make it easier for you.

The last step is to install the railings in the upper part - it is more comfortable to hold this way (you can find it in stores selling furniture accessories).

The last step is to fix the ladder - to the sidewall and floor.

Railing installation

For the installation of railing posts in the extreme board, we make cuts (according to the size of the beam used).

We mount the railing posts. They must be fastened to the logs, in full width, for this, when cutting, add the height of the log to the planned height of the railing. We fasten with nails obliquely, hammering in three nails on both sides. To hide the mount, we nail a wide board into the end. It is attached to the posts and does not fit closely. We cover the existing gap with a round plank (such as a plinth).

From the same strip we make edging for the racks - the joints are also imperfect. Saw off four pieces, joining them at an angle of 45 °.

Install a curly bar at the top. The railing is ready.

Equipment of the working area at the bottom of the loft bed

From two or three (depending on the width) relatively thin boards we make a desktop. We coat the joints with glue on wood, set them in a vice overnight. After the glue dries, we grind it to smoothness. First with coarse grain, then fine grain.

On the reverse side, we fasten the Z-shaped structure - for rigidity. We take self-tapping screws of a small length - less than the total thickness of the table top and the strip - so that the tips do not stick out. For reliability, you can grease the strips with glue, then screw it on.

In the hardware store, interesting folding hinges were found that allow you to lower and raise the tabletop. Here we attach it to the racks on them (the tabletop is made just under them in length).

There will be a shelf above the countertop. Immediately on the spot, we cut the boards of the required length - from one rack to another. When sawing, hold the saw perpendicularly so that the saw cut is at 90 °. We knock down a rectangle from the cut boards. To strictly maintain right angles, we use an angle clamp. You can connect the parts with nails or self-tapping screws - as you are used to.

Then we install the shelves into the resulting frame. During installation, we always check the horizontal position.

We put the finished structure in place and fasten it to the racks.

Finishing

Now it's up to polishing. Take a sander and a lot of sandpaper and get a smooth surface. After removing the dust, paint over with stain if desired, and on top - with two layers of varnish (it can be water-based, it does not stink). We chose a whitening compound - it seems that the structure is not so massive.

The only thing left to do was to make the bed.

Photo report 2: DIY loft bed for a girl

This version is made of wood and plywood. The following materials were used:

- timber 50 * 150 mm, 50 * 100 mm;

- plywood 15 mm thick (1.5 sheets of regular and 1 sheet of laminated on one side), and 6 mm - for boxes;

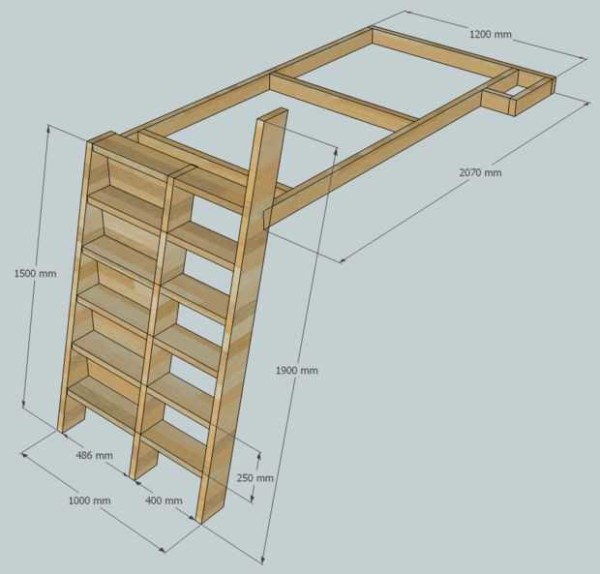

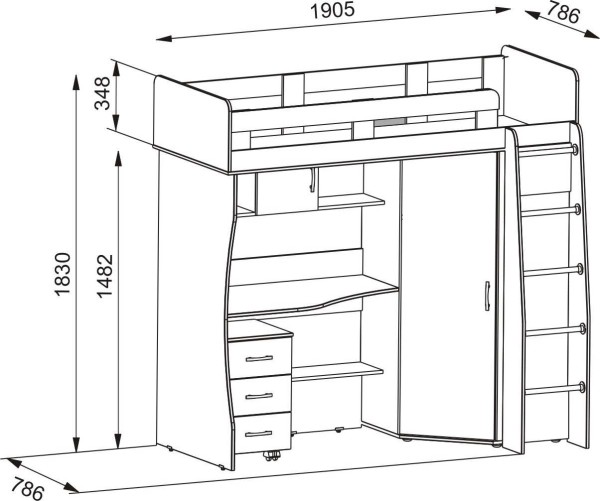

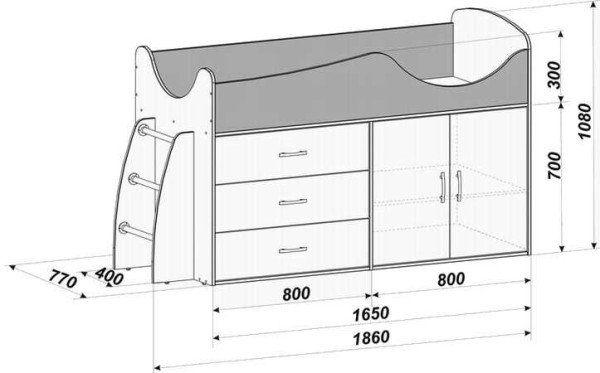

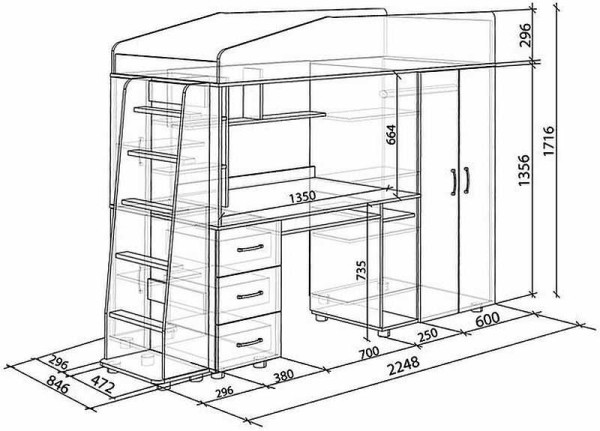

Loft bed drawing

A project was drawn up with dimensions.

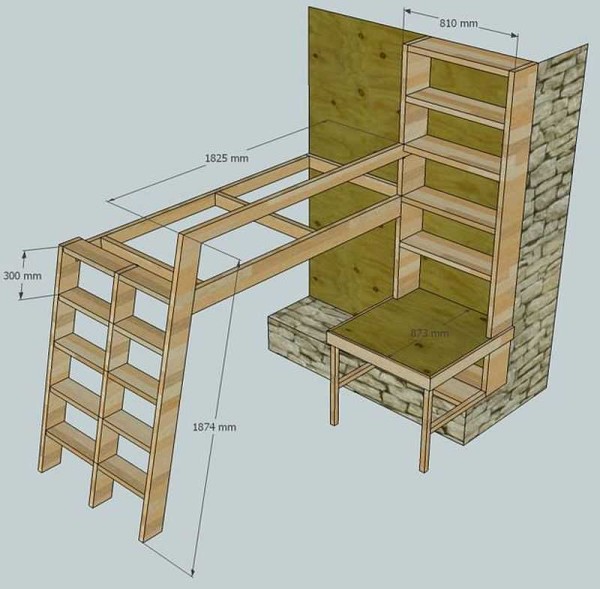

A workplace is located on one of the walls, while the rest of the space will be equipped with cabinets for storing clothes and toys.

We collect the stairs

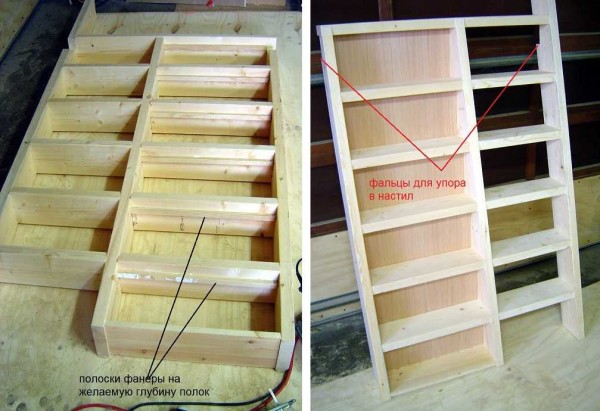

From a board of 50 * 150 mm we cut three bowstrings for stairs - two shorter, one longer (for this option, 1 * 1900 mm, 2 * 1462 mm). To create the required slope, we cut the end parts.

Every 25 cm we mark the places for installing the steps. If we take into account the thickness of the degree (5 cm), then the planned step of 30 cm will turn out. When marking, we keep the same slope as on the cuts, therefore it is more convenient to do this by placing the bowstrings.

Having prepared the required number of boards, we nail the steps. For this project, two different lengths are required - 400 mm for the part with the steps and 486 mm for the part with the shelves. The top step is made solid, its length is 962 mm. In the middle part, we screw in the screws from below, at an angle (at least 3 pcs per step), from the ends you can simply screw it through the board.

Fastening the steps, set their edge from the front side in the same plane with the edge of the racks (so that the steps do not stick out).

Shelves

One part of the ladder is used as a shelf for books, the other will rise. To prevent the books from falling, we fasten the walls of laminated plywood. First, we cut the plywood into pieces of 250 * 486 mm (six pieces according to the number of gaps) and strips of 20 * 486 mm (also six).

First we attach the strips to the steps. They serve as emphasis. Then we glue the back walls of the shelves to them.

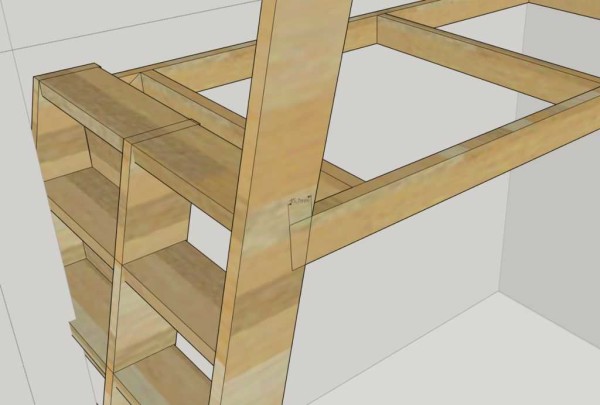

Cut the folds on the extreme bowstrings. They are needed to fix the ladder to the bed frame.

We cover all the grooves from the fasteners and chips with wood putty (you can add wood dust that remained after cutting the wood - this way the putty will not be visible at all). After it dries, everyone is compared using sandpaper and hands or a grinder.

Bed frame

First, we assemble the frame from a 50 * 100 mm board. The frame requires the following lengths: 2 * 2032 mm (side), 1200 mm (bar on the right), 2 * 964 mm - jumpers, 362 mm and 162 mm - for the ledge. We collect everything on self-tapping screws (three per connection).

We try on the resulting frame to the plywood sheet, cut it to size. We pre-drill holes in the plywood and the board, and we will install the self-tapping screws later - already on the mounted frame. The drill diameter is 1–2 mm less than the diameter of the screws.

Installation

All finished parts are painted. In this case, they are lightened. After the paint has dried, proceed with installation. Here assistants are required. It is necessary to install the frame in the grooves cut out for it on the stairs, it is also required to keep the frame itself strictly horizontal. You can use nails for temporary fastening.

When everything is level, we fasten the frame to the wall with studs. At least 4 pieces on the long side and two on the short side.

Railings

In this project, the railings are in the form of clouds.First, we make a template from cardboard - choose a shape, adjust the size. Circling the template, cut out the blanks, round the edges with a grinder.

We paint, then put in place.

The second option with a bookshelf - for a boy

The project turned out to be successful and, having slightly modified it, made a second copy for the eldest son. For him, bookshelves and a table were added to the side. The height has also changed - the boy is tall.

A few more variations on the same project in the photo gallery.

- This bed has a wide berth upstairs and shelves underneath.

- Another bed was installed downstairs

- The strength test passed))

- Diy low-rise wooden loft bed

I liked your work very much. Thanks for the ideas.

What program did you draw in? I wanted to try to draw "for myself"