home » miscellanea » How to make a brazier out of metal with your own hands

How to make a brazier out of metal with your own hands

We love, if the weather permits, with friends to fry kebabs in the open air. However, if the weather does not allow, too ... we fry. But in any weather, barbecue without a barbecue is not a serious matter. If you have a private house or summer cottage, you can make a solid stationary installation that combines a brazier and a barbecue. They are usually made partly from brick or natural stone, partly from metal. If you don't want to build something serious, you can weld a metal brazier and put it nearby - in the backyard under a canopy, in a garage, in a pantry, etc. If you are a lover of outdoor recreation in any form, you cannot do without a portable barbecue. Moreover, one that will be convenient to carry / transport. Here's how to make a brazier out of metal with your own hands and will be discussed further.

We fry kebabs when the weather permits, and when not ... that's why we need a barbecue at any time of the year

The content of the article

The size of the barbecue made of metal

Of all the parameters of metal braziers, only the height of the walls (side) remains more or less constant: it is usually in the range of 13-15 cm.If you make it smaller, nearby coals will burn the meat, if you raise it higher, you will need a lot of coals for normal frying. And we do not always have the ability or desire to wait until a sufficiently large number of them are prepared. So 13-15 cm is the smartest choice.

All other sizes of metal braziers are selected based on your personal preferences or circumstances:

- The width depends on the size of the skewers used. It should be 8-10 cm less. If you have skewers 50 cm (excluding handles), respectively, the width of the barbecue is 40-42 cm.

- The length of the barbecue depends on how many shish kebabs you plan to fry at the same time. The distance between them is about 8-10 cm. So count it. If you need to lay 8 skewers at the same time, then you need 72-90 cm long - depending on whether you will place them after 8 or 10 cm. In homemade barbecues, recesses are often made in the long walls for skewers. The recess can be triangular or rounded - whoever adapts how.

- The height of the legs is a purely individual matter. Someone does not like to bend over, and he needs a height of about 70-80 cm, while someone can fry while squatting. High legs are more often made at welded barbecues that stand near the house or in the country. For portable models, in order to save money, they are often small - about 20-30 cm.

- Metal thickness. And again, two approaches. If you are going to weld the brazier and put it on, you can use thicker metal - 3 mm or more. If it is a prefabricated modification that is transported in the trunk or generally carried in the hands, then it is better to use no more than 2 mm. If it seems to you that this is too little, you can make the bottom from 3, and the rest of the walls from thinner metal.

Sometimes they also make a second plate with longitudinal holes on the bottom, like grates. Probably, this is necessary so that the metal at the bottom does not burn out, but it is quite possible to do without this part.

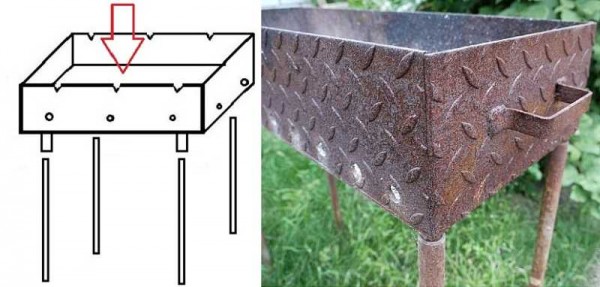

The designs of metal barbecues do not differ in special variety. This is a brazier with legs. The dimensions of the brazier and the height of the legs are all changes.There are, of course, real works of art, but there are simpler options for going out into nature.

Making stationary models

There are several ways. They are not very different, but there is still a difference.

Method one: with a minimum of welds

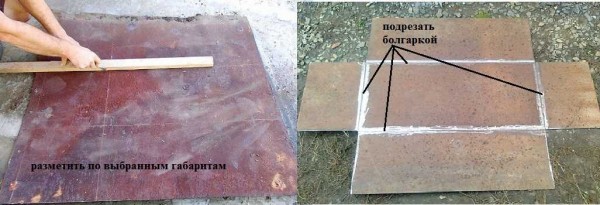

It can be used if you have a large enough piece of metal to hold the entire sweep. In this case, mark out all the dimensions found above, cut out the "extra" corners. Then carefully trim the folds with a grinder: it will be easier to bend.

We start everything by drawing dimensions on a sheet of metal, then cut out the extra corners (to increase the size of the picture, click on it with the left mouse button)

Next, we start working as a welding machine. For welding metal 2-3 mm is best suited inverter welding machines... Probably the brazier is the best product for a novice welder. There is no need for tightness of the seams. Holes are even welcome - air for combustion will flow through them. Having applied four seams, we get a finished barbecue box.

Bend the workpiece, then weld the seams (to increase the size of the picture, click on it with the left mouse button)

If thin metal is used - 1.5-2 mm, the bottom and walls can bend. To prevent this from happening, they can be reinforced with a corner or a profile pipe.

The bottom and walls can be strengthened so that they do not bend from high temperatures

Next, it remains to weld only the legs. They can be from corners, or pipes. The options are different, but both can be used. How to weld legs from pipes to a metal barbecue, see the photo. By the way, according to the same principle, you can make legs at a collapsible barbecue - select the diameters so that they fit tightly. Or weld the nuts to the bottom, and cut a thread on smooth fittings of the appropriate diameter.

How to attach pipe legs to the bottom of a metal barbecue (to increase the size of the picture, click on it with the left mouse button)

Another way to make legs from corners or a profile pipe. It's even easier here: you weld in the corners.

As legs for the barbecue, you can use an iron corner or a profile pipe of a small section

Method two: welding a lot

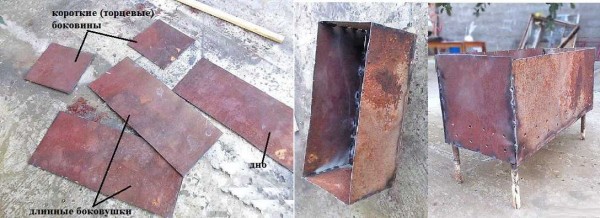

This case is suitable for you if you have metal, but it is available in small pieces. Then just cut the necessary blanks, and then weld them. In this case, of course, weld better quality is needed: their length is much greater.

The second way to make a brazier out of metal with your own hands is to cut all the necessary parts for the box and then weld (to increase the size of the picture, click on it with the left mouse button)

After the box is assembled, it remains to weld the legs. There are no differences here. Several options are described above.

How to make a gazebo made of metal for gatherings with barbecue, read here.

Method three: on a frame made of corners

The sequence of actions differs from the second option. Perhaps this is a more correct way: there is a frame here that will prevent the metal from bending. In general, such a homemade brazier turns out to be more durable. After the sequence of work is as follows:

- weld a frame from corners (in the photo on the left) or a profile pipe (in the photo on the right)

- weld the bottom to it, and after - the walls.

These metal braziers are made on a frame

Well, if you are making a brazier for yourself, with your own hands, it may make sense to provide a tabletop and / or a frame for storing skewers for comfort, as in the photo below. The brazier is reinforced with a shaped tube along the upper edge. The reinforcement is welded so that "additions" can be inserted. So both the table and the skewer stand - can be inserted or not at will.

Homemade brazier made of metal with options: a table and a stand for skewers (to enlarge the picture, click on it with the left mouse button)

And for those who like to do everything thoroughly, there is the idea of an iron barbecue under a canopy. Nicely done. Such a metal brazier with a roof was made by a novice welder.He used this project to train: learned to cook with inverter welding... A very good idea, and a good execution.

Homemade barbecue under a canopy with a "kitchen" corner (to enlarge the picture, click on it with the left mouse button)

If you are interested in barbecues that are quickly made and do not require special skills, pay attention to barbecues from gas cylinders.

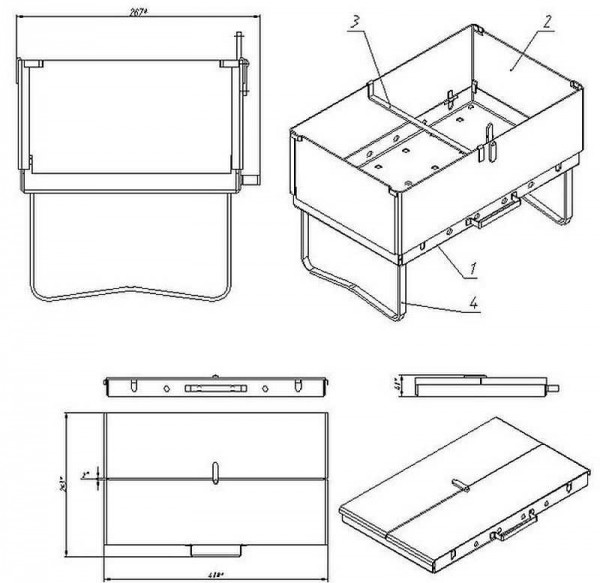

Do-it-yourself collapsible metal brazier

For trips to nature, hunting or fishing, a lightweight portable collapsible option is more suitable. There are similar products in stores, but they are made of very thin metal and they last for a long time. Therefore, it is better to make a portable brazier with your own hands.

They are of several types:

- folding;

- prefabricated.

Folding (folding) braziers in a suitcase and without

Folding barbecues are made most often in the form of a suitcase. Some of them have handles for carrying. Others require a separate case or some sort of suitcase diplomat.

Brazier in a suitcase is a good idea (to increase the size of the picture, click on it with the left mouse button)

In this version, the owner made a brazier out of metal under the existing suitcase. Parts are attached to metal door hinges. They were welded with manual electric arc welding. Specifically, this model's legs are painfully thin, but these are the costs of compactness.

Another option for a portable camping barbecue. It can also be “packed” in a suitcase, but you can also sew a canvas bag: cheap and cheerful.

Another brazier that you can put in a suitcase (to increase the size of the picture, click on it with the left mouse button)

In this version, the bottom is made with folding legs. The rest of the parts fit inside separately. The sidewalls are fastened to each other by cuts that go to the middle of the height in different directions.

Another design of a folding brazier is shown in video format.

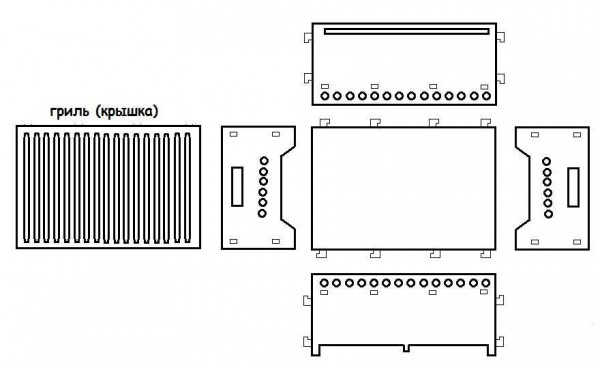

Collapsible braziers

They differ from the previous ones in that they consist of separate, unattached parts. Collected on site. The assembly methods are different - somewhere there are several bolts, somewhere - grooves and cuts. When manufacturing, welding is not needed, but you will need a grinder with a diamond disc or a saw for metal.

The prefabricated metal brazier shown in the photo resembles a children's designer. The idea is interesting, the implementation is excellent. Welding is not needed, but mastery of the grinder is necessary. If there is no skill of this level, you can finish the most difficult places with a saw for metal. If you decide to do something like this with your own hands, first make a layout in cardboard. It is advisable to take it the same thickness as you will use the metal. Assemble the finished layout, adjust it so that everything is perfect. Then you can transfer the patterns to the metal.

Brazier made of metal without welding is made of stainless steel (to increase the size of the picture, click on it with the left mouse button)

The following folding barbecues are made according to the type of those sold in stores. In them, the legs are made from corners, cuts are made in the legs in the form of tongues. These tabs are slightly bent. Holes are made in the sidewalls for these projections. When assembling, the sides are "pushed" onto the tabs.

A collapsible barbecue made of metal - it's easy to do it yourself (to increase the size of the picture, click on it with the left mouse button)

The bottom in such a model of a prefabricated barbecue is not fixed by anything. The lower part of the sidewalls is bent inward by 3-4 mm. After fixing them on the legs along the perimeter, a side is obtained. The bottom fits onto this side. Having experience in operating just such a model, I can say that the structure turns out to be quite wobbly and you need to behave with it carefully: having installed it, you will not move it, otherwise everything may fall apart. But our grill is made of a very thin metal of 1 mm. Perhaps, if you use a large thickness, there will be no problem.

Another version of the prefabricated barbecue differs from the previous ones in that its legs are forged. Sidewalls are attached to them due to special plates.

Collapsible brazier on forged legs (to increase the size of the picture, click on it with the left mouse button)

And you will see the simplest of the metal braziers in the photo below. If you have two pieces of a corner and a grinder, you can make it in a few minutes. If you cannot bend, you can drill holes and fasten with a bolt and nut.

The simplest metal shashlik maker. You can do it yourself in a few minutes

Install it over the fire pit, hammering the legs into the ground. Not very convenient, but very simple. On the "fire" case will come down.

How to paint a metal brazier

If rust on metal bothers you a lot, you will have to peel it off by hand. It is advisable not to use any chemicals, work only with brushes, skins. You can paint it if you want. But paints should be heat-resistant, and even better - heat-resistant, because only they can withstand the burning temperature of firewood. There are several options:

- heat-resistant paint CERTA (Certa) withstands up to + 900 ° С, there is a different name for the same paint OS-82-03T;

- heat-resistant enamel Rust-oleum, can be usedup to + 1093 ° С, matte, sometimes in white, gray, black;

- heat-resistant enamel (paint) "KO-8101" can withstand heating up to + 650 ° C, there are twelve basic colors;

- heat-resistant enamel KO-8111 Thermica also has anti-corrosion properties, withstands heating up to + 600 ° C.

If you want the grill was beautiful, take a look at the brick... They create a downright monumental impression. Even the simplest ones. You can practice on simple models.

Blueprints

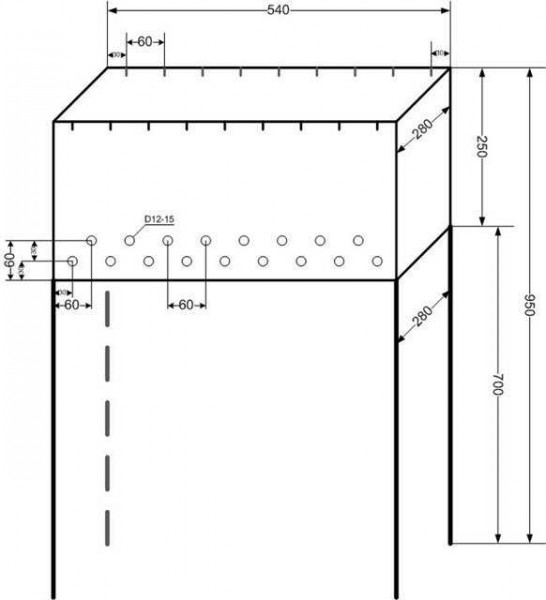

And finally, a few drawings. Change the dimensions at your discretion, there is no crime in this.

Drawing of an iron barbecue on high legs

-

Buying an apartment: what documents are required, their verification

Buying an apartment: what documents are required, their verification

-

How to deal with cockroaches in an apartment, the best remedy for cockroaches

How to deal with cockroaches in an apartment, the best remedy for cockroaches

-

How many square meters in a hundred square meters of land: measurement, calculation

How many square meters in a hundred square meters of land: measurement, calculation

-

Conversion of inches to cm and mm, centimeters to inches, tables, applications, formulas

Conversion of inches to cm and mm, centimeters to inches, tables, applications, formulas

-

Floor stands for flowers

Floor stands for flowers

It is best to entrust this business to professionals, namely, go to the store and buy a good brazier) It seems to me that you should not save on such things. I once bought pob3000 from a grill, but the grill is not cheap, but the thoughtfulness in the details greatly simplifies the cooking process.

As I understand it, the comment was written by the manufacturer's representative? Not a weak barbecue for 16 thousand rubles 🙂

Well, given its characteristics, this is a normal price) I would certainly not buy one for myself, but I understand why they take such things.

Not everyone has free money to buy a barbecue, especially an expensive one. It is much easier to do it yourself and for yourself, especially if your hands grow from the right place. And rukozho * s can buy.