How to build a pigsty yourself

It is better to raise pigs in a specially designated room, and not together with other livestock. You can build a pigsty with your own hands from any inexpensive material in your area. It is important to know the features, correctly calculate the sizes and proportions.

The content of the article

Dimensions and layout

The size of the pigsty depends on the livestock you plan to keep. The area required for pigs at different ages is different, as is the number of animals that can live in one pen. To make it easier to navigate, the data are tabulated.

| Livestock | Number of animals in the pen | Area per head for breeding | Area per head when keeping for fattening |

|---|---|---|---|

| Boars | 1 | 8 sq. m | 8 sq. m |

| Sows single and pregnant up to 2 months | 4 | 3 sq. m | 2 sq. m |

| Sows are 3 months pregnant | 2 | 6 sq. m | 3.5 sq. m |

| Sows pregnant at the 4th month | 1 | 6 sq. m | 6 sq. m |

| Suckling sows with piglets | 1 | 10 sq. m | 7.5 sq. m |

| Piglets up to 5 months | 10-12 | 0.6 sq. m | 0.5 sq. m |

| Breeding pigs 5-8 months | 5-6 | 1.15 sq. m | |

| Breeding boars 5-8 months | 2-3 | 1.6 sq. m | |

| Fattening piglets 5-6 months | 20 | 0.7 sq. m | |

| Fattening piglets 6-10 months | 15 | 1.0 sq. m |

Based on these dimensions, it is necessary to plan a pigsty. It makes no sense to make many pens of different areas, therefore, they basically make two sizes of 3 * 4 m - for sows with piglets and keeping the rest of the livestock and 4 * 4 meters - fattening pens.

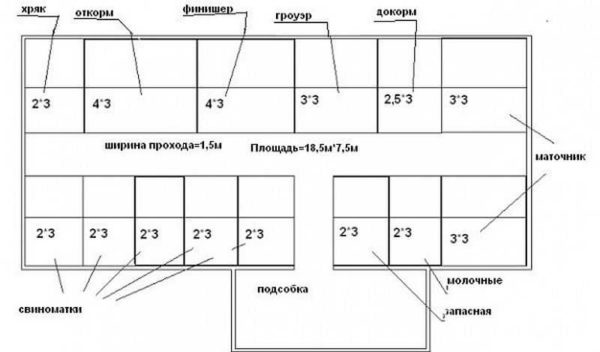

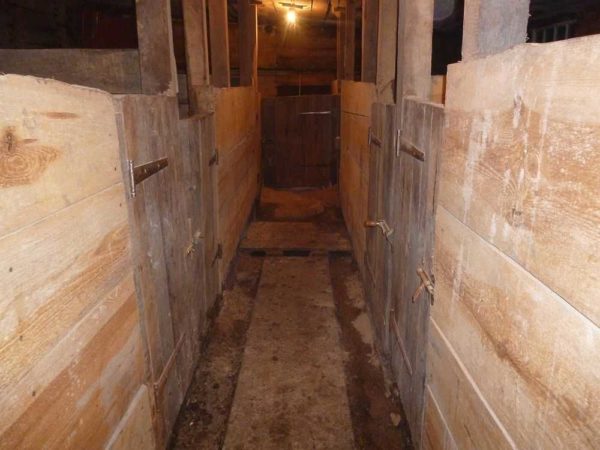

If the width of the building permits, machines (stands, corrals) are placed on both sides of the central aisle. For convenient maintenance, the passage width is at least 1.5 meters. In total, the total width of the pigsty is about 10 meters. The length depends on the planned livestock. An example of a two-row arrangement of machines is in the photo below.

If the building is not wide, the corrals are made on one side, it is not recommended to make the passage already inconvenient to work. If necessary, it is better to make the machines less deep or slightly less than the norm in size.

In addition, it is necessary to provide for the presence of a walk - a summer area with a canopy. In warm weather, pigs spend most of their time outdoors. This has a good effect on the rate of mass gain. Also at this time you can close the shed for repairs.

Quite good design of the pigsty - with a fenced-off walk for each of the pens (look at the photo).

- View from the street

- This is before "check in"

- This is a pigsty with a walk from the inside - each barn has its own exit to the street in a fenced-off pen

- This is a walk for piglets, for pigs more solid partitions will be needed

If necessary, you can make the pigsty wider, with a passage from the rear of the pens - for easy maintenance. A similar option is in the following photos. The entrance to the pigsty is on the one hand, walking is on the other.

- A fenced-off walk on the other side of the building

- For the convenience of service, it is better to have a fenced-in corridor in a walking pigsty

Foundation

For pigsties most often do strip foundations... Other types of bases are rarely used. Sometimes you can see pile or columnar, usually with a grillage.

The foundation tape is made shallow (60-70 cm deep) and, basically, only along the perimeter, since the common space is fenced off only by low partitions - one meter in height.If a separate room is made, then it is fenced off with very light walls, more often from boards (usually this is a utility room for storing inventory). No base is required for such partitions; support in the floor is sufficient.

If you are planning to build a pigsty with your own hands, the question may arise: pour a monolithic tape or do prefabricated strip foundation made of ready-made concrete blocks. Monolithic will cost less, but block is built faster.

For the normal keeping of pigs, the premises must be dry. Therefore, when building a foundation, do not forget about waterproofing. It excludes the suction of moisture from the soil. It is laid between the foundation and the walls. It is advisable to coat the foundation with liquid waterproofing (bituminous mastic, for example), and lay waterproofing or other similar material on it.

If the walls are made of foam concrete of another hygroscopic material, it is advisable to make a base from a material that does not absorb moisture. Most often, two or three rows of bricks are placed on the foundation, on top of the waterproofing, waterproofing again (with a coating), and only then they continue to fold the walls. This is especially true with a high level of groundwater.

What and how to make walls

Pigsty walls are best made of lightweight and warm material. This category includes all blocks from lightweight concrete (foam concrete, expanded clay concrete, aerated concrete, etc.). They have one drawback - they absorb water, therefore, immediately after construction, such structures must be plastered inside and out. But it is easy to build such pigsties on your own - the blocks are large and light, the buildings are warm and relatively inexpensive.

There is one more material that fits into this category, but is not very used yet - arbolite... It is made from a mixture of shaped wood chips and cement with water. Keeps warm well, durable and strong, can be made independently.

In some regions, shell-rock pigsties are being built. An excellent natural building material, it is a pity that it is not available everywhere. Brick is used quite rarely. Firstly, it is expensive, and secondly, it is cold and the walls definitely require insulation.

- Pigsty from a bar - OSB is sewn on the outside (next photo)

- Beams under the sheathing. In such a pigsty without heating in winter + 15 ° C

- Made up of old sleepers

Often they build pigsties from timber and even sleepers. They turn out to be warm, light enough. In order not to blow from the cracks, they are caulked like a regular log house, and outside they are sheathed with sheet material (moisture-resistant plywood, OSB) and painted on top. In general, a tree is considered not the best material for a pigsty - pigs can gnaw it perfectly, but if there is nothing to cling to, the surface is even, then the walls will be intact.

Wall height

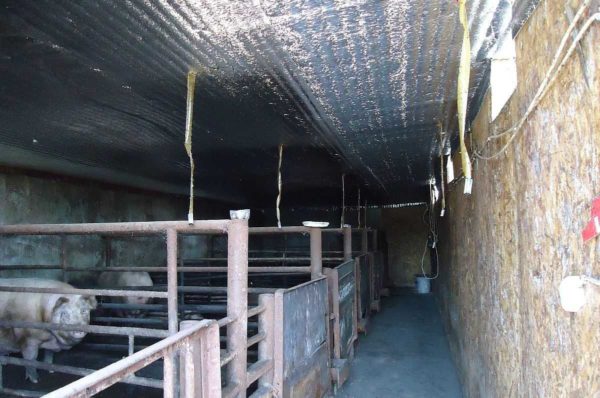

The pigsty should be warm in winter, cool in summer and well ventilated to ensure fresh air and normal humidity. In this regard, very low ceilings should not be done - with small volumes, you will often have to ventilate, which will negate the heating benefits. Too high walls - high heating costs, which is also not good. The best option is a ceiling of 2.3-2.5 m.

The height of the walls is 1.7 m, the height in the ridge is 2.5 m. A vapor barrier has been laid along the rafters, there will be more insulation, from below it will fit with a board (without an attic)

Sometimes they make the ceiling sloped, without an attic. It is still practically not used in any way, since there is high humidity. In this case, the walls are low - 1.7-1.9 m, and in the center, the ceiling is raised to 2.5-2.8 m. This makes it possible to minimize the cost of walls, but increases the cost of roofing.

Interior decoration

The walls inside the pigsty are best plastered, then whitewashed or painted.Whitewashing is disinfection and good looks, but as long as the wall is not splattered. Then the view is not the most attractive - until the next whitewash. To prevent dirt from sticking to the walls, they are coated with resin diluted in gasoline. The height of such processing is about 1 meter. From such a wall, dirt flies. It looks a little gloomy, but easy to clean.

Another option is to beat the entire machine with boards around the perimeter, as in the next photo. It is easy to clean and animals do not lean against the cold wall in winter.

Roof and ceiling

It is more profitable to make the roofs of the pigsty single-pitched - less costs. With a large width of the building, gable roofs are made, since with a span of more than 8 meters, the cost of installing a gable roof is almost the same as that of a gable.

Regardless of the type of roof, the attic is rarely done. If they do, they don't use it. The roof is insulated, as usual, with mineral wool. From the side of the room, a vapor barrier membrane is stuffed, from the side of the roofing material, they are covered with a waterproof vapor-permeable film.

Roofing material - any, the most affordable in the region. Usually it is slate, soft roof ordecking... The ceiling is hemmed from the inside with a board, plastic or plywood, OSB.

Pigsty floor

The most difficult and controversial question is how to make a floor in a pigsty. The opinions are different. Here are the most common methods with their advantages and disadvantages:

- Wooden flooring. They are made from edged boards 50 mm thick, nailed close or with a very small gap. Advantages - the floor is non-slip, warm. Disadvantages - it absorbs urine and odors, swells from high humidity, quickly collapses. Disinfection is possible, but difficult to carry out, cleaning is not the easiest.

- Concrete floors. With a high grade of concrete, the surface is smooth, almost does not absorb water and odors, it is easy to clean, lasts a long time, and is not afraid of high humidity. The disadvantage is that the concrete is cold, but there are several options for eliminating this disadvantage:

- For the winter, shields knocked down from boards are thrown on the floor.

- They make a heated floor - heated from water heating or electric cables.

- When constructing a concrete floor, it is made multi-layer, with heat-insulating layers.

- Asphalt pavement. Non-slip, warm enough and reliable, but porous, it is difficult to wash, particles remain in the pores, it is problematic to wash them even with a “karcher”. Over time, acids and alkalis erode the surface, it becomes sticky.

- Earthen floor. Of the advantages - only cheapness. Everything else is solid shortcomings: cold, absorbs urine, mixed with manure, difficult to clean, the smell lasts constantly. Another disadvantage is that pigs love to dig the ground, and they may well make a tunnel under the wall and escape. You can only imagine how everything can end. So the earthen floor in the pigsty can only be used as a temporary option. Please note that when installing a different floor, a decent layer of soil will have to be taken out, otherwise the amber will be indestructible.

- Brick, filled with concrete. Herringbone bricks are laid on the tamped ground, tightly to each other. The gaps between them are poured with concrete. Such a floor is warmer than concrete, but it has all its advantages. The only drawback is the rather high price (unless you use a used brick).

When building a pigsty with his own hands, each owner usually chooses from these options the one that seems preferable to him.

Slatted floor device

A few words about urine diversion and manure disposal. Despite the widespread belief that pigs are unclean, they quickly get used to defecate in one place (there are exceptions, but not often). Therefore, many people prefer to make double floors - at the bottom they make something like a trough of concrete with an inclination towards the ditch, and on top they lay slatted floors.Slots may not be over the entire area, but only in a certain area. This is where the "decent" pigs go to defecate.

Slatted floors are concrete, metal and plastic. Plastic and metal are used for small pigs - the surface of the flooring is made a little ribbed and rough, the gaps are very small.

Slatted concrete floors are produced in series. They have small hole sizes and wide bridges. This is done to minimize injury. In general, the design of the slatted floor greatly facilitates the work, it is easier to maintain cleanliness in the pigsty.

In order to save money, a slatted floor is sometimes made from thick boards. But this is not a good idea - pigs can catch on the cracks and turn the boards out.

How to make a solid

In order to make the continuous floor easier to clean, a ditch is made along the machines, and the floor slopes towards this ditch (2-5%). The ditch is most often laid out of bricks and plastered. Then it goes into the storage tank, for a normal outflow it must also have a slope.

The collected masses are either transported by special vehicles or pumped into pits for rotting and fermentation - for fertilizers. By the way, the lower part of the slotted pilaf is made according to the same scheme, only the ditch is located under the upper deck, and not in the passage.

Insulated concrete floor

Whatever they say, but the most practical, relatively inexpensive and reliable floor for a pigsty is concrete. In fact, it has two serious flaws. One thing has already been said - in winter it is cold. Second, it takes a long period of time for its final hardening (28 days from the moment of pouring). If you flood the floor while the livestock lives in the summer enclosure, there is no particular hurry, and you can fight the cold. For example, make it insulated.

For arranging the insulated concrete floor in the pigsty, the soil is taken out to a depth of 40 cm. The bottom of the pit is leveled and tamped. About 10 cm of crushed stone is poured, it is also tamped well (it is better to pour and separately tamp two layers of 5 cm each - there will be no cracks). 5 cm of sand is poured onto the tamped crushed stone, rammed so that a footprint does not remain. On top, put waterproofing (you can have a dense plastic film), pour insulation - expanded clay or granulated foam glass. Expanded clay is cheaper, but foam glass in granules is better (it is 3 times warmer and does not absorb moisture, which is very important). The insulation is tamped, but not as seriously as a cushion of rubble and sand. Pour concrete of grade B 20 (for 1 part of cement, 2 parts of sand and 4 parts of crushed stone are taken). The minimum layer thickness is 3 cm; during pouring, the required slope is formed towards the ditch.

If you do this, the floor will not be so cold, you will have to heat less.

Regular cleaning

The need for cleaning is determined by the construction of the floor. If it is a normal sloped floor, manure has to be removed every feeding - three times a day. Slit floors are generally washed once a day. Additional cleaning may be required if there are unruly animals - then they take a broom or shovel and take out the manure on the floor. But it takes several times less time than when cleaning a regular floor.

Cleaning the floor in a pigsty can be done with more than just a hose. It turns out much faster and better from "Karcher". At first, animals may be afraid, then they themselves crawl under the stream. They must be washed from a decent distance, otherwise there may be injuries.

Pigsty windows

Pigs can do without daylight, but then the lighting must be turned on, and with constantly increasing tariffs, these are unjustified costs that greatly reduce profitability. Therefore, the windows are made large enough, but their total area should not be more than the floor area - excessively bright lighting makes animals aggressive.The best lighting for them is dim light.

The windows are installed at a height of 1.5-1.7 meters, at least half of them must open. This is necessary for ventilation - optimal humidity and fresh air are needed for normal weight gain. And without airing this cannot be achieved. And although there should be good ventilation in the pigsty, there should be no drafts - animals get sick because of it. Therefore, they either make double glazing in wooden frames, or put plastic ones. There is little trouble with them - they are convenient to use, easy to clean.

Ventilation

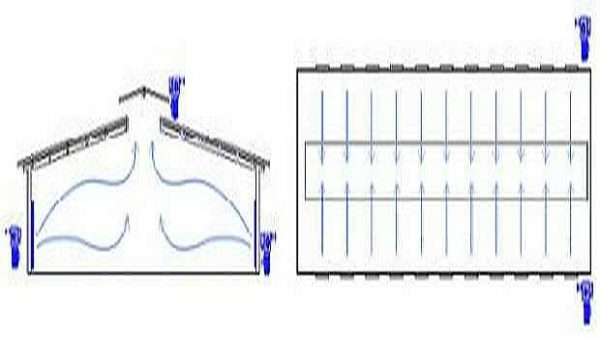

As has been said many times, there must be ventilation in the pigsty. The most primitive way is to make exhaust pipes that start from the ceiling and make air inlets. Install adjustable dampers on the supply air pipes, and gates on the exhaust pipes (for the furnace type - discs that can rotate opening / closing the pipe lumen). With their help, you can adjust the intensity of air exchange.

Often the role of supply ducts is played by windows. This is not a very good solution - in the pigsty they are located high, in which case a stagnant zone forms at the bottom, namely the pigs are at the bottom. Therefore, it is better to equip the air inlets 20 centimeters above the floor, pick them up with metal grates. Such ventilation works on the principles of natural air movement - warm air rises, cold air comes in its place, and all this is whipped up by the wind outside. But there is a complete calm, and usually in the very heat, which the pigs tolerate already poorly. For such situations, fans are placed in the air inlets. They are rarely included in work, but they save the situation if there is no walk.

What to make machines for pigs

When they build a pigsty with their own hands, they usually divide the room into machines using two materials:

- edged board 50 mm thick and timber for racks;

- metal pipes, sheet, corners.

The choice is really simple: what is cheaper, what you know how to work better with, or do you think it is more reliable. In principle, both options are not bad and are widespread.

The height of the partitions is about 1 meter; a separate entrance is made to each corral. Wickets should be well locked, and simple bolts are unreliable, they are pushed off with spots and doors are opened.

- Piglet sow pen - separate piglet pen

- Wood floor in the pigsty

- Pig feeder

- Feeder, a different angle

- Pig pen fence made of rebar and steel strips