Types of gable roof truss system: for small and large houses

At the heart of each roof is a large number of beams, rafters, posts and purlins, which are collectively referred to as the rafter system. Over the centuries-old history of types and methods of its organization, a lot has accumulated, and each has its own characteristics in the construction of nodes and cuts. We will talk in more detail about what the rafter system of a gable roof can be and how the rafters and other elements of the system should be attached.

The content of the article

The structure of the gable roof truss system

In section, the gable roof is a triangle. It consists of two rectangular inclined planes. These two planes are connected at the highest point into a single system by a ridge bar (run).

Gable roof scheme

Now about the components of the system and their purpose:

- Mauerlat - a beam that connects the roof and walls of the building, serves as a support for the rafter legs and other elements of the system.

- Rafter legs - they form the inclined planes of the roof and are the support for the sheathing under the roofing material.

- Ridge girder (bead or ridge) - combines two roof planes.

- Tightening is a transverse piece that connects opposite rafter legs. Serves to increase the rigidity of the structure and compensate for bursting loads.

- Beds are bars located along the Mauerlat. Redistribute the load from the roof.

- Side Girders - Supports the rafter legs.

- Racks - transfer the load from the girders to the benches.

Fillets may still be present in the system. These are boards that lengthen the rafter legs to form an overhang. The fact is that to protect the walls and foundation of the house from precipitation, it is desirable that the roof ends as far as possible from the walls. To do this, you can take long rafter legs. But the standard length of lumber of 6 meters is often not enough for this. Ordering a non-standard is very expensive. Therefore, the rafters are simply grown, and the boards with which they do it are called "filly".

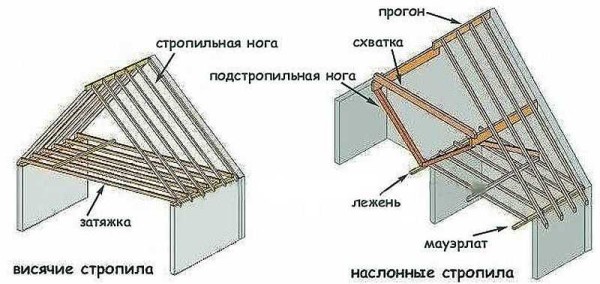

There are quite a few constructions of truss systems. First of all, they are divided into two groups - with layered and hanging rafters.

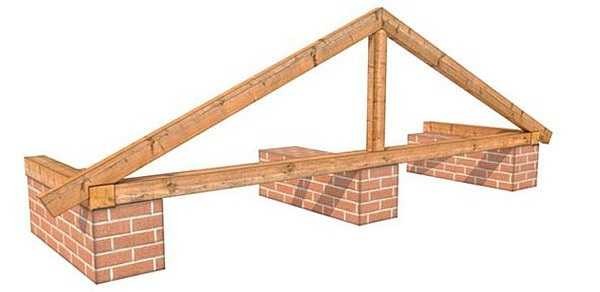

The difference in the design of the layered and hanging rafters

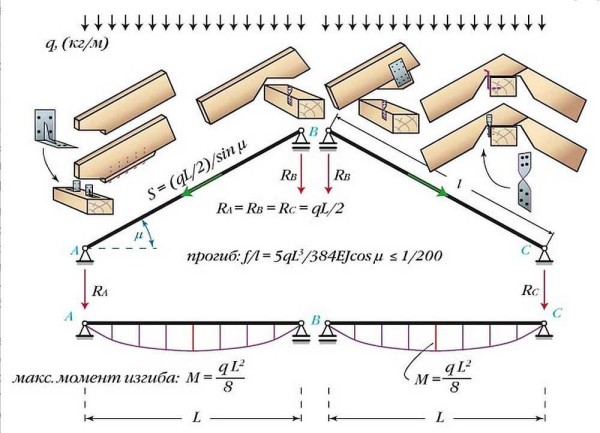

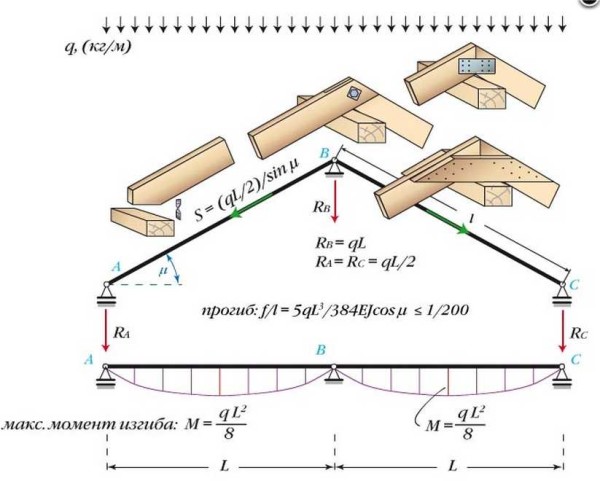

With hanging rafters

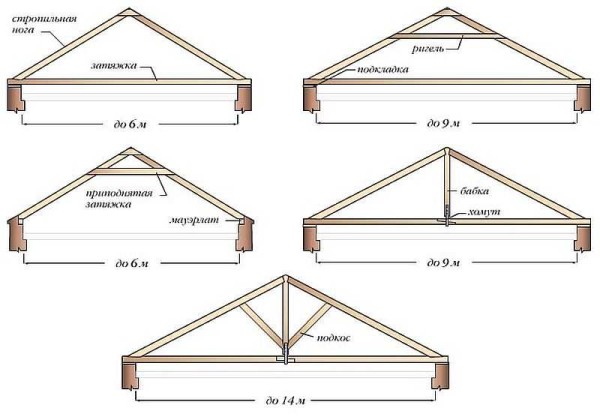

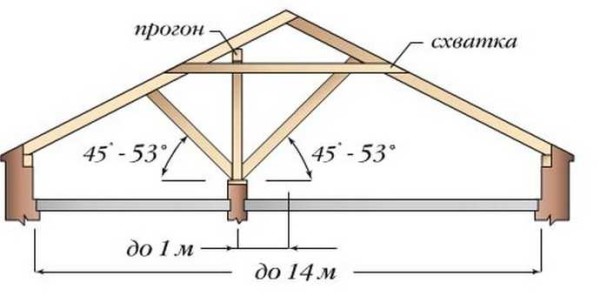

These are systems in which the rafter legs rest only on the outer walls without intermediate supports (load-bearing walls). For gable roofs, the maximum span is 9 meters. When installing a vertical support and a brace system, it can be increased up to 14 meters.

The hanging type of gable roof rafter system is good because in most cases there is no need to install a Mauerlat, and this makes the installation of rafter legs easier: you do not need to make cuts, it is enough to mow the boards. To connect the walls and rafters, a lining is used - a wide board, which is attached to studs, nails, bolts, crossbars. With such a structure, most of the bursting loads are compensated, the effect on the walls is directed vertically downward.

Gable roof rafter system for small houses

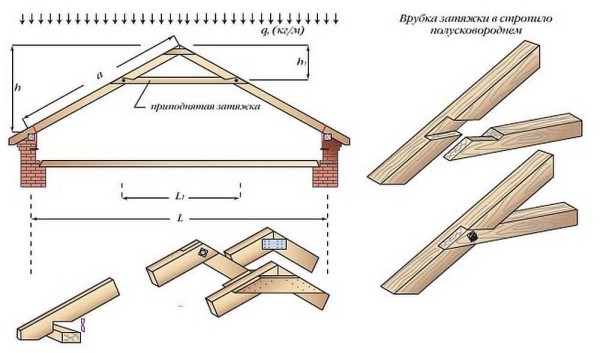

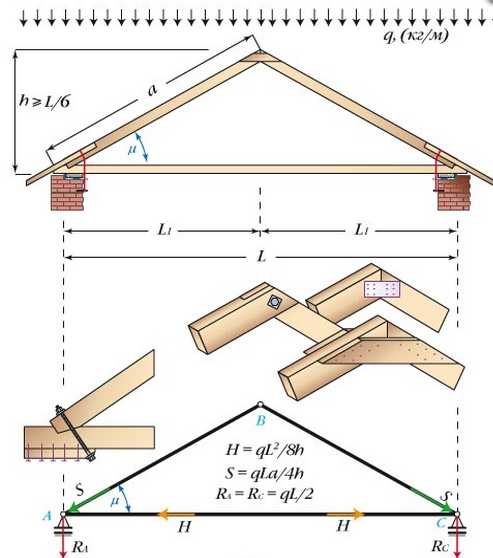

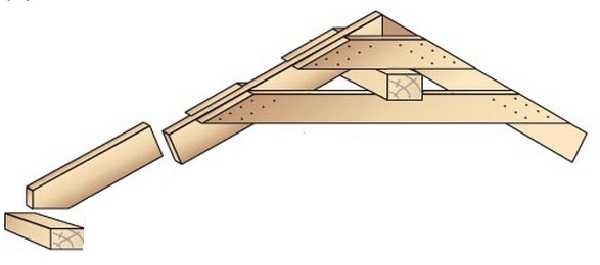

There is a cheap version of the rafter system when it is a triangle (photo below). Such a structure is possible if the distance between the outer walls is no more than 6 meters.For such a rafter system, you can not calculate the angle of inclination: the ridge must be raised above the tightening to a height of at least 1/6 of the span length.

But with this construction, the rafters experience significant bending loads. To compensate for them, either rafters of a larger section are taken or the cutting of the ridge part is made so as to partially neutralize them. To give greater rigidity in the upper part, wooden or metal plates are nailed on both sides, which securely fasten the top of the triangle (also see not the picture).

The photo also shows how to extend the rafter legs to create a roof overhang. A cut is made, which should go beyond the line drawn up from the inner wall. This is necessary in order to displace the notch and reduce the likelihood of breaking the rafter.

Ridge knot and fastening of rafter legs to the backing board with a simple system version

For mansard roofs

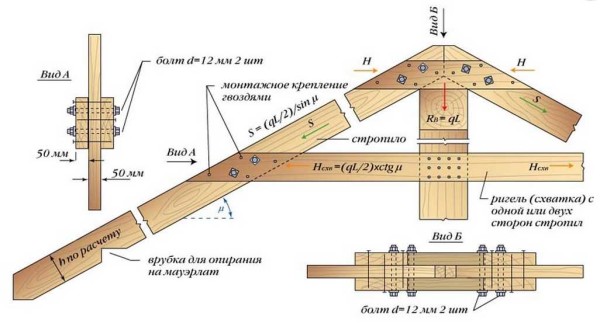

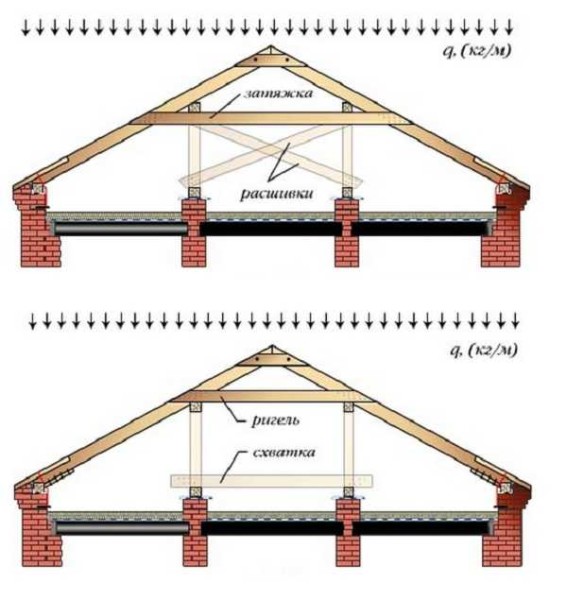

Crossbar option - used when organizations under the roof of the living space - attic... In this case, it is the basis for filing the ceiling of the room below. For reliable operation of this type of system, the crossbar cut must be non-hinged (rigid). The best option is semi-rotten (see the picture below). Otherwise, the roof will become unstable to loads.

Please note that in this scheme there is a Mauerlat, and the rafter legs should extend beyond the walls to increase the stability of the structure. To fix them and dock with the Mauerlat, a cut is made in the form of a triangle. In this case, with an uneven load on the slopes, the roof will be more stable.

With this scheme, almost all the load falls on the rafters, therefore they must be taken of a larger section. Sometimes the raised tie is reinforced with a suspension bracket. This is to prevent it from bending if it supports the ceiling sheathing materials. If the tightening is short, it can be secured in the center on both sides with boards nailed to the nails. With a significant load and length of such insurance, there may be several. In this case, too, planks and nails are enough.

For large houses

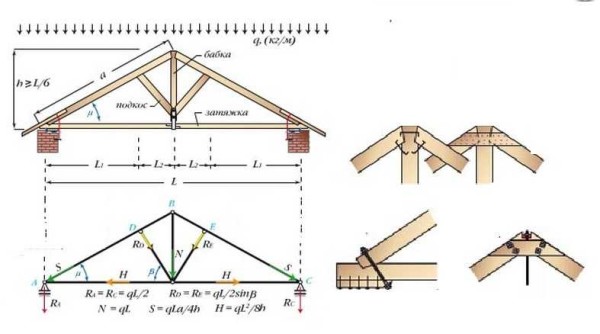

With a significant distance between the two outer walls, a headstock and struts are installed. This design has high rigidity, since the loads are compensated.

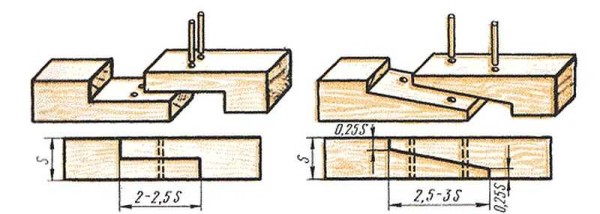

With such a long span (up to 14 meters), it is difficult and expensive to make an integral tightening, therefore it is made of two beams. It is connected with a straight or oblique cut (figure below).

For a secure fit, the joint is reinforced with a bolted steel plate. Its dimensions should be larger than the dimensions of the cut - the extreme bolts are screwed into solid wood at a distance of at least 5 cm from the edge of the cut.

In order for the circuit to work normally, it is necessary to make the braces correctly. They transmit and distribute part of the load from the rafter legs to the tightening and ensure the rigidity of the structure. Metal pads are used to strengthen the connections

Attaching the struts for the truss system with hanging rafters

When assembling a gable roof with hanging rafters, the cross-section of lumber is always larger than in systems with layered rafters: there are fewer load transfer points, therefore, each element has a large load.

How the attic roof is arranged (with drawings and diagrams) read here.

With layered rafters

In gable roofs with layered rafters, their ends rest on the walls, and in the middle part they rest on load-bearing walls or columns. Some schemes burst the walls, some don't. In any case, the presence of a Mauerlat is required.

The simplest version of layered rafters

Spreader-free schemes and cutting units

Houses made of logs or beams do not respond well to spacer loads. For them, they are critical: the wall can fall apart. For wooden houses, the rafter system of a gable roof must be non-thrustable. Let's talk about the types of such systems in more detail.

The simplest spreader-free diagram of the rafter system is shown in the photo below. In it, the rafter leg rests on the Mauerlat. In this version, it works for bending without bursting the wall.

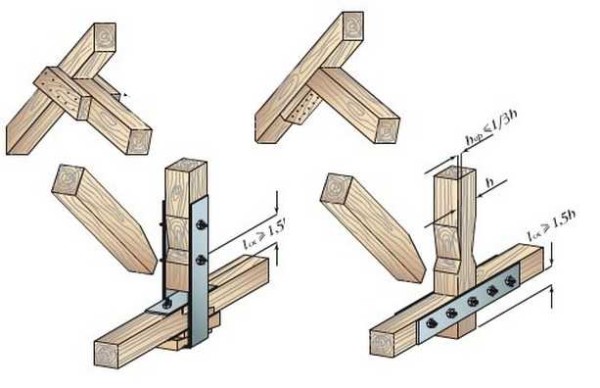

Pay attention to the options for attaching the rafter legs to the Mauerlat. In the first, the support area is usually beveled, while its length is no more than the section of the beam. The depth of the cut is no more than 0.25 of its height.

The top of the rafter legs is laid on the ridge beam, without fastening it to the opposite rafter. The structure turns out to be two pitched roofs, which in the upper part adjoin (but do not connect) one to the other.

It is not recommended to do such a scheme without experience: at the slightest inaccuracy of execution, thrust forces appear and the structure becomes unstable.

It is much easier to assemble the version with rafter legs fastened in the ridge part. They almost never give space to the walls.

For this scheme to work, the rafter legs at the bottom are attached using a movable joint. To secure the rafter leg to the Mauerlat, one nail is hammered from above or a flexible steel plate is placed from below. For the options for attaching the rafter legs to the ridge run, see the photo.

If the roofing material is planned to be used heavy, it is necessary to increase the bearing capacity. This is achieved by increasing the cross-section of the elements of the rafter system and strengthening the ridge assembly. It is shown in the photo below.

Reinforcement of the ridge knot for heavy roofing material or with significant snow loads

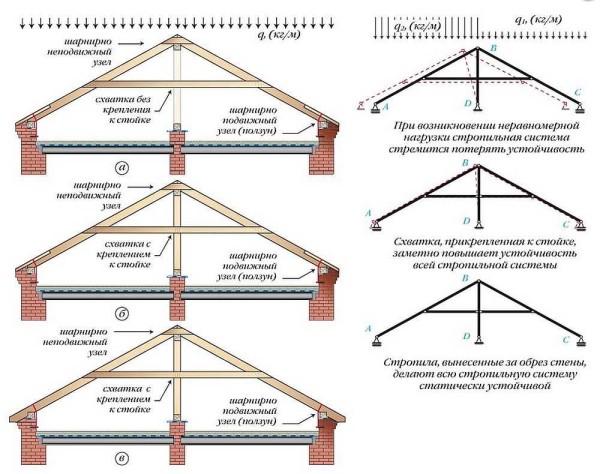

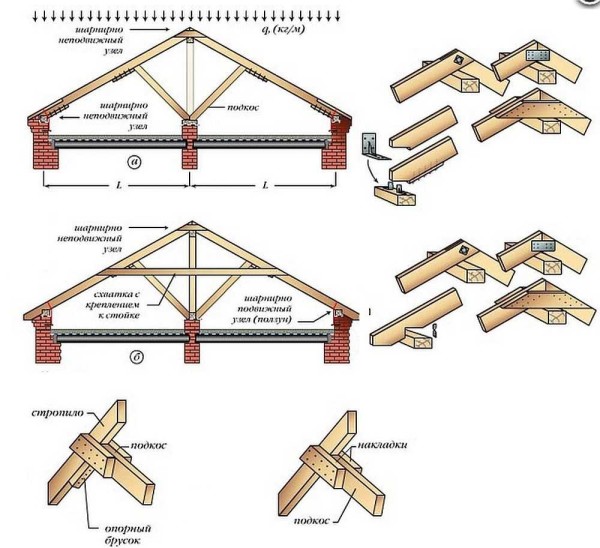

All of the above gable roof schemes are stable in the presence of uniform loads. But in practice, this practically does not happen. There are two ways to prevent the roof from sliding towards a higher load: by installing a scrum at a height of about 2 meters or with struts.

Variants of rafter systems with scrapes

Installation of scrapes increases the reliability of the structure. In order for it to work normally, in the places of its intersection with the drains, you need to fasten it to them with nails. The cross-section of the timber for the fight is used the same as for the rafters.

Attached to the rafter legs with bots or nails. Can be installed on one or two sides. See the figure below for attaching the scrum to the rafters and ridge girder.

Attaching the scrum to the rafter legs and ridge bar

In order for the system to be rigid and not "crawl" even under emergency loads, it is sufficient in this version to provide a rigid fastening of the ridge bar. In the absence of the possibility of its horizontal displacement, the roof will withstand even significant loads.

How to make a gable roof (photo report) read here.

Systems of layered rafters with struts

In these options, for greater rigidity, rafter legs are added, which are also called struts. They are installed at an angle of 45 ° to the horizon. Their installation allows you to increase the span length (up to 14 meters) or reduce the cross-section of the beams (rafters).

The brace is simply placed at the required angle to the beams and nailed from the sides and bottom. An important requirement: the brace must be cut accurately and fit tightly to the uprights and rafter leg, excluding the possibility of its deflection.

Systems with rafter legs. A spacer system on top, a non-spacer bottom. The nodes of the correct felling for each are located next to each other. Below - possible schemes for attaching the strut

But not all houses have the middle load-bearing wall in the middle.In this case, it is possible to install struts with a tilt angle relative to the horizon of 45-53 °.

Rafter system with off-center vertical purlins

Strut systems are necessary if significant uneven shrinkage of the foundation or walls is possible. Walls can sit in different ways on wooden houses, and foundations on layered or heaving soils. In all these cases, consider the device of this type of rafter system.

System for houses with two internal load-bearing walls

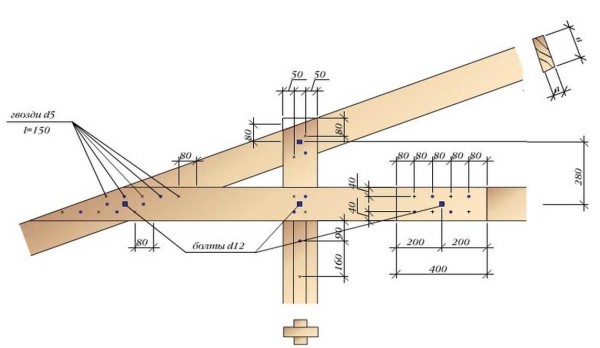

If the house has two load-bearing walls, two truss beams are installed, which are located above each of the walls. Benches are laid on the intermediate bearing walls, the load from the rafter beams is transferred to the benches through the racks.

Systems with truss beams

In these systems, the ridge girder is not installed: it provides thrust forces. The rafters in the upper part are connected to one another (they are cut and docked without gaps), the joints are reinforced with steel or wooden lining, which are nailed.

In the upper non-thrust system, the tightening force is neutralized by the tightening. Please note that the tightening is placed under the purlin. Then it works efficiently (top diagram in the figure). Stability can be ensured by uprights, or by joists - beams installed obliquely. In the spacer system (in the picture it is below), the cross member is a crossbar. It is installed above the purlin.

There is a variant of the system with racks, but without the rafter beams. Then a stand is nailed to each rafter leg, which rests on the intermediate load-bearing wall with the second end.

For fastening the posts, 150 mm nails and 12 mm bolts are used. Dimensions and distances in the figure are in millimeters.