How to make a bench: original ideas (drawings, photo reports)

Benches and benches in the country and in the garden are, first of all, a place of relaxation. But just putting a bench is not interesting. After all, you can create a beautiful corner. In order not just to relax, but to enjoy nature and the fruits of your labor. There are many interesting ideas. Moreover, often the simplest designs are played up such that these benches with their own hands can be made by any person whose arms grow from their shoulders.

The content of the article

Photos of original benches (ideas for a summer residence and a garden)

Everybody knows what ordinary benches look like - they've seen it more than once. But the usual - the simplest - something you don't want. Especially if you have already begun the process of decorating the site or are just planning. Why not start with the bench? And there other decorations will catch up. One has only to start.

In the garden or near the house, you want to have more greenery: beautiful and different flowers. Flower beds and flower beds - that's good, but why not combine them with a bench.

What could be easier? Two wooden boxes in which flowers are planted and between them a couple of planed and polished boards. This bench can be placed near the wall, and a couple of long boards can be stuffed on the wall - there will be a back.

Not everyone likes wood beds: wood requires care, and without it, it quickly loses its appearance. It is especially difficult to care for a tree that is in contact with soil. Instead of wooden boxes, there can be, for example, stone or concrete pedestals.

It is quite easy to make such a bench in the country with your own hands. You can find ready-made concrete beds or something similar. You can buy a processed board, or you can do it yourself. Instead of a board, there can be half a log - depending on the style of the site. It is easier to fix the seat with a metal corner. It is attached to concrete with dowels, to wood - with screws from below or bolts through and through.

If someone has large plants in sturdy flowerpots, the following idea can be implemented. In this version, the bench covers the plants. To avoid surprises, flowerpots must be very durable….

There is a similar version of a bench made of boards and without plants: maybe you need to veranda or in gazebo put. The supports are folded from boards of the same size, and the seat is from a bar.

And more variations on the same theme: hollow building blocks are used as a support. Processed bars are inserted into the holes. This is the seat of the bench. Only round the edges of the timber, or it will be uncomfortable to sit.

For this garden bench, it is advisable to find large blocks with thick walls. If not, you need to securely fasten the blocks to one another. The whole task is to fix the blocks first (for example with pins), and then bars (bolts or dowels) to them.

Log benches

If your site is decorated in a rustic or ethno style, the standard approach will not work for you. It is best to use logs in this case - with or without bark - this is your choice.

Seat for a bench made of logs - sawed along a trunk of large or medium diameter. The back is either a smaller trunk in diameter, or just a cut closer to the edge. Legs can also be made from narrow pieces of logs (see the photo below).

The legs and seats are connected to each other by metal pins: a slightly smaller hole is drilled under the pin in both parts. The pin is hammered into one of them, the second part is pushed in and is also hammered, but they are no longer hitting the pin, but against the wood. So that there are no traces left, they put a piece of unnecessary board and knock on it with a hammer (or a sledgehammer). Such a connection should be quite reliable, but to be sure, you can install two or three pins, or you can cut a little log by making a flat area of the same size on both parts to be joined. By increasing the support area, increase the seat anchorage: all the same, the log weighs a lot.

Another interesting option in the "ethno" style is shown in the photo above. It is realized in stone, but this bench can also be made from a log. The seat is a very thick board, the legs are most of the large diameter deck. A groove is cut in the deck for laying the seat. If you have a tool (with an ax, a grinder or a chainsaw, you can make a cutout) it is easy to do.

Often a desk is needed in the country. You can make not only a bench from a log, but also a table. A variant of such an ensemble is shown in the photo. Only the table top is made of boards, all other parts are logs of different diameters or from half.

A greater degree of processing is inherent in the next bench in the same style. The back, legs, armrests are made of thick and not very branches, the seat is made of sanded and processed (peeled from bark and sanded) unedged boards.

Another bench is almost also made. Only the boards and branches are located in a different direction and a different look is obtained. A DIY bench of this type does not require much skill. In this case, the more carelessly the work turns out, the more decorative the result.

Around the tree, you can make a resting area and a bench. The constructions are simple, it is so easy to make the flooring.

You can add a rest group swing and gazebo... And above the bench you can put pergola - this is the "progenitor" of the usual arch - one of the types of light arbor. And to make the relaxation really complete, you can do pond, the fountain or waterfall.

Of metal and wood

Few people will put completely metal benches at their dachas. They, of course, can be very beautiful, but in summer they heat up to incredible temperatures, and if it gets a little colder, you cannot sit on them, as they are too cold. Metal and wood benches are devoid of these shortcomings. The legs and supporting structure are made of metal, while the seat and backrest (if any) are made of wood. Moreover, there are also interesting shops in modern design.

Rectangles are welded from the profile, jumpers are welded to the side walls, on which the seat boards rest. Simple, stylish, reliable, functional.

In a more advanced form - with armrests, a back, soft cushions on the seat, such a design can look like in the photo. The wide seat turns the bench into a sofa, while pillows - upholstered furniture foam rubber - add comfort. The tables are made in the same style - a frame made of professional pipes and a tabletop made of boards.

One important point: if you are making a seat or tabletop from several adjacent elements, they do not need to be butted together. There should be a gap of 3-4 mm between adjacent boards / planks. Wood swells and dries up. For these processes to keep the surface relatively flat, a gap is required.

If smoother lines are needed - for families with children - you can bend the pipes and make garden benches and a table with rounded edges. This garden furniture is completely safe. An ordinary round or professional pipe is bent, leaving on the sides in the shape of the letter "P" with a wide back.The length of this back is the length of the bench. For the table, the dimensions are made a little larger: the legs and and the back are longer.

Make two identical blanks for the table and bench. Next, the boards are cut to the same length. For a seat about 40 cm, for a table top at least 55 cm. Fix to pipes with furniture bolts with a flat head. To prevent the hats from sticking out, a hole of a slightly larger diameter is drilled under them.

ABOUTFor the basics of site planning, read here, and how you can decorate it - in this article.

Benches from boards

The most numerous group is benches and benches made of boards. There are designs that look more like sofas, especially if soft pillows are laid on them - and you can lie down.

It is easy to assemble garden furniture in a modern style: rectangles with partitions made of thinner boards, connected to each other.

Even the usual design of a summer cottage can become exclusive if you approach it with imagination: instead of legs and armrests, wooden wheels are used. The result is a designer thing.

And the simplest possible - a board with legs in the form of the letter "X". Such shops were built centuries ago, you can still see them today.

From the boards you can make a bench in a modern style: in the form of the letter "P". With this design, the main task is to ensure a rigid fixation of the legs and seat: the expanding forces are not compensated by anything. In this case, it is important to take a thick board or timber so that it does not bend. You can put the board "on the edge": this way the rigidity will be greater. To increase reliability, you can install corners from below.

In the photo there is a version with a cut at 45 °. Having a miter box or circular saw, it is not difficult to achieve an accurate cut. Precisely joining the workpieces and fastening them together, we get an angle of 90 °. If the seat does not bend, it will serve for a long time ...

An interesting and reliable version of the bench is presented in the photo below. The legs are assembled from boards of different lengths: each second is shorter by the width of the seat board. Interesting idea. It is easy to make such a bench: it is important to maintain the dimensions, and everything is connected very simply: with nails in the face of the seat.

You may be interested to read, how to design and make garden paths.

Original benches

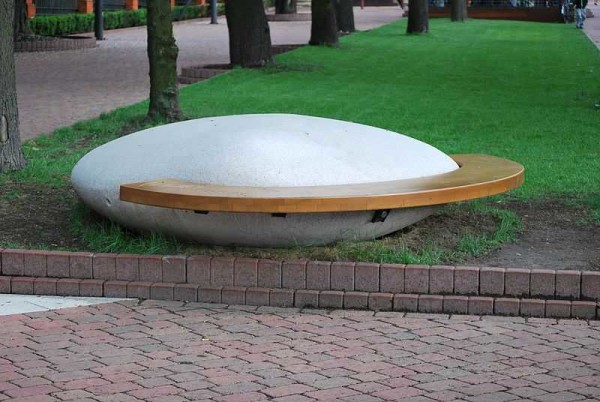

Here, it seems that you can still think of ... but it turns out, a lot. For example, attach the seat to a large stone.

Make a structure out of bamboo trunks.

Or a stone.

Read about what swings are (for adults and children) and how to build them here... And in this article you can read on the construction of a playground, about sandboxes is written separately - here.

How to make a bench: photo reports

We will not make benches out of stone - not everyone has equipment, but we can use different pieces of wood. Let's talk about making simple but unusual designs. To make a do-it-yourself bench a source of pride.

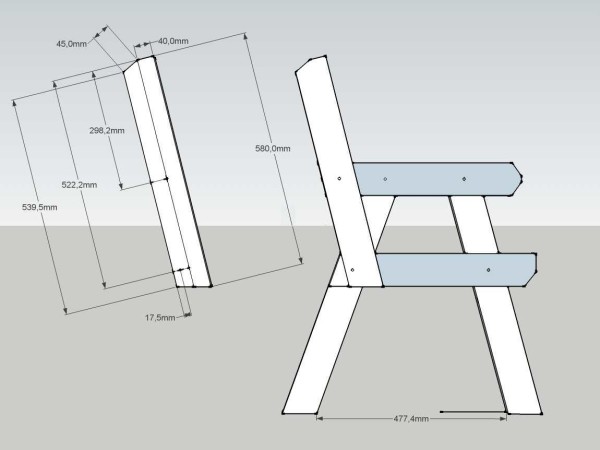

Backless bench

The design is simple, but it looks interesting due to the specific material. For the legs, a bar with rounded edges is used. If you have small logs, you can trim them on the sides. You will get almost the same effect. Such material is not such a rarity, the legs are unusually collected from it: the bars are laid flat on top of one another. This adds flavor and attractiveness.

This bench without a back has a length of about 120 cm, a width of about 45 cm, a height of 38 cm. You can round off the edges of the timber using a cutter, or you can find a similar profiled one. It costs more, but it will be easier to work with it: it is already well processed and it is easy to connect.

Depending on the found section of the timber, you will calculate the length that you need. Determine how many bars you have to stack one on top of the other to get the height you need. In this case, it took 5 bars per leg. Total 45 cm * 5 pieces - 2.25 m. 4.5 m of timber was needed for two legs. The seat used a board 40 mm thick and 90 mm wide. For the seat, you need 5 boards 1.5 meters long. It turned out 1.2 m * 5 pieces = 6 m.

First, we cut and process the boards for the seat. Their edges must be rounded. If you don't have a sander or milling cutter, you will have to work with sandpaper, but you can find such a board or arrange at a sawmill to have it processed and polished: there will be much less work. So, we cut the boards to the same length, grind and varnish (with or without tinting - your choice).

Fold the leg blocks one by one, aligning their edges. Using a square and a pencil, draw lines where the fasteners will be placed. The distance between the lines is 7-10 cm.

You can take metal pins, or you can make pins - carved from wood. For them, holes are drilled slightly less than the diameter, the depth of the hole is half the length of the pin. Then they are hammered into one piece, and a second piece is inserted into the same hole from above. The connection is reliable, but for confidence you can add glue, although then the structure will turn out to be one-piece.

With a pin connection, the main task is to make the holes strictly one above the other, so that the parts mounted on the pin give an even edge. We did part of the work - we drew the lines where we will drill, now it is necessary to measure the same distance from the edge. For this we will create a template. We take a piece of plank with a width of about 1.5 cm. At this distance from the edge of the bars, we will drill holes. Applying it exactly along the edge, mark the intersection with the drawn perpendicular lines.

We will install the pins in a checkerboard pattern, so we will drill holes through one intersection. We also make holes on one bar from different sides in a checkerboard pattern. In a similar way - on the pins - the legs are connected to the seat: two pins for each bar.

Technologically, this type of connection is correct, but it is complex and requires a certain skill. You can do it easier. Fold all the bars one on top of the other, secure with clamps, drill through in two or three sets - in the center and along the edges, connect with a long hairpin, with washers placed under the cap and nut. The legs of the seat strip assembled in this way can be nailed from above or try to make a pin connection.

If the seat has been nailed down, take a little wood polish of a suitable color, add some very fine sawdust and stir. Coat the joints with this compound. When dry, smooth with a sandpaper. Sand all parts to a smooth state and cover with varnish or wood paints for outdoor use (preferably not covering, but which leave the texture of the wood visible).

How and with what you can paint wood read in this article... It is about lining, but the painting techniques remain the same, and the compositions must be taken for external use.

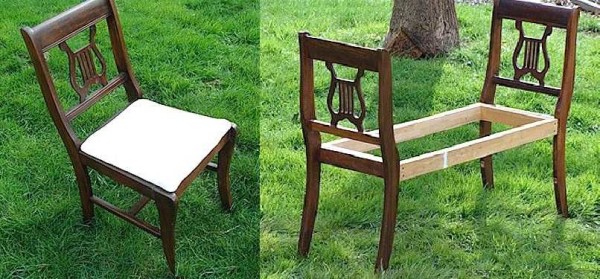

Do-it-yourself bench from broken chairs

In any household, you can find two old chairs. They must be the same and still strong enough. We disassemble the chairs, leaving the part with the back and legs. We connect the two backs using bars of a suitable section.

For greater rigidity below, at a distance of about 20 cm from the floor, where earlier the chairs also had jumpers, we make another frame with transverse beams. It can be used as a footrest or for storing things.

After grinding, paint the resulting structure. This time the paint should be normal: different types of wood can only be painted over with covering paints. Apply with a brush or spray.

The matter is small: cut the seat from thick plywood (thickness 8-10 mm) to size and cover it with foam rubber and fabric.

Chair / bench for garden from pallets

Everything is useful on the farm. You can even make garden furniture from cargo pallets. Moreover, there is no need to disassemble them: we use one for the seat, from the second we will make a back. All you need is well-finished armrests and leg blocks.

In one of the pallets we strengthen the attachment points by inserting pieces of bars. After inserting, fasten them with self-tapping screws from one side and the other.

From a bar with a cross section of at least 100 * 100 mm, cut four identical segments with a length of 80 cm. We fasten them in those places that have just been reinforced. We leave 20-25 cm on the legs. Fasten with four long self-adhesive screws - 150 mm and not shorter.

It is important to be vertical and keep the same distance on the legs. Then the seat will be level. If there are errors in height, you can try to file it, but then you will have to saw it from above so that the armrests are even. So try to screw it straight. Deviations from the vertical can only be fought by screwing the leg back.

We attach the second pallet to the rear uprights, and on the sides - planks for the armrests.

It remains to cut a piece of furniture foam rubber and cover it with fabric. You can also make pillows for the back. If you are not going to process everything thoroughly, but to make a loft-style chair, walk with sandpaper or a sander, treating all surfaces to smoothness. You can paint it with paint, which gives the wood a dark color.

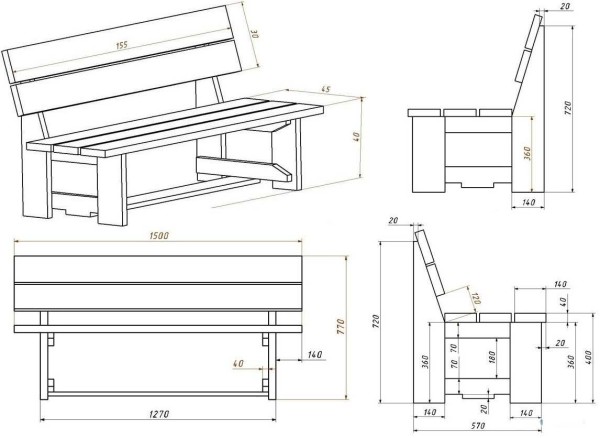

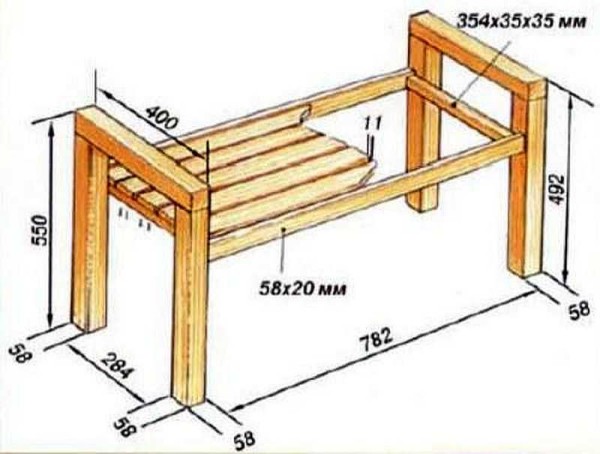

Drawings of wooden benches

Video lessons

Several videos on how to make do-it-yourself benches.

cool article. and great ideas)