Facing the basement of the house with your own hands

The basement of the house performs not so much a decorative function as a practical one. In many cases, it serves to reduce heat loss (it is specially insulated), and also prevents the spread of atmospheric and underground moisture to the walls of the house. It also transfers the load from the walls to the foundation - if the foundation is strip or slab. Therefore, the facing of the basement of the house should be not only beautiful, but also functional. In accordance with this task, the finishing material is also selected.

The content of the article

- 1 When to start finishing the base

- 2 How to veneer the basement of the house

- 3 Preparation and insulation

- 4 Painting, plaster and "fur coat"

- 5 How to fix porcelain stoneware or clinker tiles

- 6 Decorating the basement of the house with natural stone (shell, granite, dolomite, slate)

- 7 Facing with a boulder or small cobblestone

- 8 How to install plastic (PVC) plinth panels

- 9 Finishing the basement of the pile foundation

When to start finishing the base

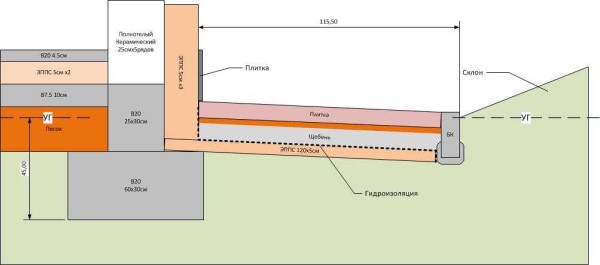

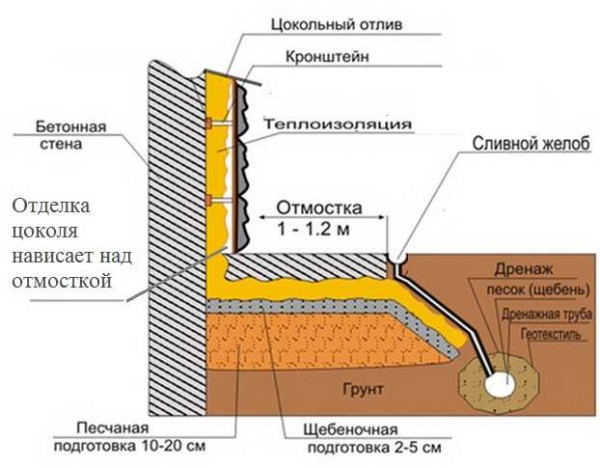

It is best to finish the plinth after it is done blind area around the house... In this case, the finishing material will hang over the track. As a result, even the most oblique rain or streams of water flowing down the walls cannot get between the wall and the blind area - water enters the path at a distance of several centimeters from the junction. Namely, it is through this joint that water penetrates to the foundation, bringing dampness and other problems.

You need to start facing the basement of the house after the blind area around the house has been made

One more point. Many are thinking about whether to insulate the basement or not. If you want to save on heating, the answer is that you must insulate, like the blind area. The basement insulation and cladding unit - one of the options - is shown in the photo below.

When using the basement floor as a residential one, there are no questions about insulation, since the answer is unambiguous - of course, insulate. But even if you don't have a subfloor, heating costs will be much lower and the floor in your home will be much warmer.

How to veneer the basement of the house

There are a lot of materials for finishing the basement. The main requirements are moisture resistance, frost resistance, strength. The following materials meet these requirements:

- Natural stones (flagstone) sawn into plates or chipped, the so-called "torn stone":

- sandstone (plastushka);

- granite;

- marble;

- slate;

- dolomite;

- shugnit.

- Small cobblestone.

- Large river pebbles.

- Clinker tiles (clinker bricks).

- Paving slabs.

- Porcelain stoneware.

- Finishing brick.

- Facade panels, basement siding, PVC panels (these are all names of one material).

- Plaster (decorative and "under a fur coat").

- Decking.

Some of them cost a lot, some are insignificant, but all of them can be used. They choose the material based on financial capabilities and previously used finishing materials - an aesthetic component also plays an important role. The technologies for finishing plinths with different materials will be discussed.

Preparation and insulation

First of all, if the existing base is uneven, its surface is leveled with plaster. The mortar for plastering the basement is used cement-sand: for 1 part of cement (Portland cement M 400), 4 parts of pure building sand, preferably river sand, are taken. For greater plasticity, you can add a little lime or liquid soap (50-80 g per bucket of solution). The solution should be of medium density so as not to crawl off the wall. There is another option - to use a special composition. For example, such as in the video.

If then laying tiles, stone or other similar material follows, after leveling the mortar, notches are made on its surface with the tip of a trowel (spatula). They are applied as a grid over the entire surface.These shallow grooves will provide the necessary support for the finish.

If the base is insulated, notches are not needed. Plates of EPS (extruded polystyrene foam) or polystyrene foam are glued directly to the plastered surface. They are lightweight and adhere well to glue. Their surface is coated with diluted tile glue and pressed against the plaster. Finishing materials are then attached to the surface prepared in this way.

Painting, plaster and "fur coat"

In principle, if the plaster is well leveled, after the mortar has dried, the surface can be painted and it will stop there. It is an inexpensive but viable option. If the paint was taken from the front, which is intended for use on the street, the base will look good for a couple of years. Then you will have to remove the old paint and paint again - to maintain the appearance.

The next way is to apply a layer of decorative on top of ordinary plaster. And again, choose those formulations that are intended for external use. They can be tinted in the desired color or colored. The only drawback is that the plasters are often porous and you have to brush off the splashes of dirt that get on the walls during bad weather, and sometimes with a detergent.

Types of decorative plaster for finishing the basement: beautiful and relatively inexpensive

Until now, in some areas, the method of finishing the basement "under a fur coat" is popular. This is when the solution is applied not in an even layer, but in small fragments. Previously, they did it with a broom made of twigs. They dipped it in a liquid solution, hit the stick with the handle so that the spray flew onto the wall. This is how they made a “fur coat” - a finish with a torn surface. Today there are special plastering machines powered by a compressor. With their help, such a finish is easier to make.

Decorating the basement of a house using materials in the form of slabs or tiles is technologically more difficult. To prevent it from falling off, you need to know some subtleties.

Read how to brick a house here.

How to fix porcelain stoneware or clinker tiles

If heavy materials such as porcelain stoneware or clinker bricks are simply planted on glue, on a plastered surface with grooves, they may adhere normally. And they can even stand for a while. Even for several years. But then they will begin to fall off along with the solution. Especially in places where there are no grooves or they have insufficient depth. To improve adhesion, an impregnation layer can be applied to improve adhesion (adhesion), but this is not a guarantee, especially if the material is heavy.

The same picture will be if the materials are glued directly onto the insulation. The surface is smooth, easy to glue. But after a while, the finish will drop. Faster than a plastered surface. The video is about this.

To prevent this from happening, it is necessary to fix a metal painting net, preferably galvanized. It is fixed with dowels, putting a piece of galvanized steel on the dowel-nail, the size of which is larger than the size of the cell. Fastened at the top, bottom and staggered in the middle. It turns out a reliable basis for material of any weight.

The glue is applied to the base and the tiles. On the tile, remove with a notched trowel, put it in place, tapping the handle of the trowel, put it in place, leveling the plane. The distance between the tiles is maintained using crosses, only their thickness is taken as significant 3-5 mm.

In general, the laying technology is similar to laying tiles... The only difference is that the glue must be special for outdoor use. The second difference: finishing materials for the basement begin to be laid from below: they are heavy and need support. You lean on the bottom row on the blind area, on it - the second, etc.

Decorating the basement of the house with natural stone (shell, granite, dolomite, slate)

No matter how attractive the artificial shiny surfaces may seem, the rough stone for some reason evokes great sympathy.But laying a foundation from rubble is difficult and not everyone can do it so well that a house can stand on it. But to finish the finished monolithic or prefab foundation Anyone can use natural stone with their own hands, especially if at least part of the house construction work is done personally.

It is clear that no one will fix whole stones: the finish will be too heavy, and very bulky. Therefore, they invented a stone to slab or chop. Depending on the technology, either a flat "flagstone" is obtained - with almost flat surfaces, or a "torn stone" with an uneven face. Sometimes these materials are cut into identical rectangles, sometimes they are left in the form of uneven plates, but in any case, this is a natural stone and the decoration of the basement of the house from it turns out to be beautiful and waterproof.

There is this material made from expensive stones, for example - marble, there is cheaper - slate, dolomite, shugnite, lemesite, granite, etc. They look very impressive. Especially if it is a torn stone, although flagstone sometimes looks no worse.

Part of the offer of natural finishing stone in a specialist store

The preparation of the surface will be exactly the same: it is best to fill a paint net on the plastered base, and on it, lay the stone plates on the glue. If they are even - a natural stone with processed edges - the laying technology will repeat one to one that described above.

If the stone has ragged edges, finishing the basement of the house becomes more difficult: it is necessary to select plates of such a shape so that the seams are not too large. When using this option for a finishing stone, a grinder with a stone disc will be needed: most likely, you will have to file the plates of the lower and upper rows. Correction will also be needed when shaping the corners. See the video for an example of such technology.

There is a second way. The plastered surface of the base is first coated with a compound to improve adhesion (adhesion), then fragments of the finish are installed on it on the glue. They are fixed in a given position using cuttings of the same stone or pieces of materials of the required size. The seams remain unfilled. After the glue has "grabbed" the seams are filled with a thin solution from a construction syringe, rubbing and vomiting as necessary.

In any case, the glue that gets on the finish must be removed in a timely manner. It will be very difficult to do this with a frozen one, and the glue looks far from attractive.

Sometimes, for a clearer pattern, the seams between the stone plates are painted with dark paint. Then the surface is covered with a protective impregnation. It gives the stone a light sheen and also often increases its water repellency.

For an example of facing a basement with natural stone using the second technology, see the following video.

About cladding the house with siding is written here.

Facing with a boulder or small cobblestone

You don't need to buy a boulder or cobblestone. It can be collected on a river or on a pebble beach on the sea. Rolled stones are chosen flatter - round ones are more difficult to "mount". The procedure and all other subtleties are almost the same as in the case of natural stone finishing. The only difference is that these stones must be washed in water with detergent before use. Firstly, the water in our bodies of water can have oils and they need to be removed, and secondly, they can be in clay or algae, which can cause the finish to fall off.

To make everything look organic, you can put a "picture" of the cobblestone cladding on the path next to the place where you will be facing the basement. They have different shades and their random combinations are not always attractive. Having laid out everything side by side, you will have an idea of what will happen as a result.

Watch the video about the features of finishing the basement with cobblestone.

How to install plastic (PVC) plinth panels

This type of finish is called differently: basement or facade panels, basement siding.They have a varied appearance: for different types of stone, tiles, bricks.

To install PVC panels on the plinth, you need to assemble the frame. It is made from a wooden bar 50 * 50 mm. Since the finish will be outdoors, the wood must be protected with impregnations that prevent rotting and protect from pests.

The sequence of actions is as follows:

- Using a level (laser or hydro level), the required finishing height is marked at all corners of the house.

- In these places, nails are nailed (screws are screwed in), a marker (string) is pulled between them, which marks the height of the plinth finish.

- A timber is nailed along this cord along the entire perimeter of the house. Its top edge should be exactly directed along the line.

- If the height of one panel is not enough, you will need to make another row of timber, on which two sheets will join, and you will also need the same strapping under the lower end of the panel.

Another finishing material for the basement is PVC panels, which are also called "basement siding"

- After about 50-60 cm, short transverse bars are packed - they will prevent the PVC panels from bending.

- Installation is started from one of the corners. There are special elements to decorate the corner. They are fixed on the crate with wood screws.

- The edges of the sheets of plastic facade panels are uneven - with projections. The edge of the first from the corner must be cut exactly. This can be done with a jigsaw or a grinder, a hand saw with a metal blade (fewer teeth, you get a smoother edge).

- The trimmed edge is inserted into the corner piece. At the top and bottom of each panel there are perforations for fasteners. It is in them that the screws are fixed. Only they do not need to be tightened to the end: a backlash is required for thermal resizing. Therefore, the perforation is made of an oblong shape, and it is better to install the self-tapping screw in the middle: when the size is changed, the panel will move freely and will not burst.

- The next element is joined with a special lock, and is fixed in the same way.

The assembly is simple. Only after fixing, it will be necessary to make ebb tides from above: the crate and panels have a fairly decent volume and a gap remains on top. You can close it with roofing iron, as in this video. Immediately see the technology of finishing the base with plastic panels.

Likewise, the base can be finished with corrugated board. There is only one remark: it is advisable to lay insulation in the voids between the crate. It will be much warmer in the house.

Finishing the basement of the pile foundation

As you know, pile foundation there is no base. But if you do not block the space, there are drafts under the house, the floor will always be cold, and all kinds of animals love to settle under the house. Therefore, the base, although decorative, is necessary. It can be done in two ways.

- A trench is dug along the perimeter between the supports, removing the fertile layer of earth and deepening 10 cm into the ground, the bottom of the trench is rammed, gravel bedding is laid, and again compacted if possible. Then 2-3 bars of longitudinal reinforcement (10-12 mm) are placed and everything is poured with concrete. After 10-14 days, a wall is placed in a half-brick on a concrete base. You can use finishing bricks right away, or you can fold them from used ones, and then finish them with any of the methods described above.

- This method is suitable for finishing the basement with facade panels (basement siding) or corrugated board. A frame made of impregnated timber is attached to the piles. The rest of the finishing process is no different from the standard. Is that the fact that this option is very desirable to insulate.

The easiest way to finish the pile foundation is to attach some kind of slab finishing material to the frame

There is one subtlety if the house is installed on screw piles or piles TISE... Such foundations are often placed on highly heaving soils. So that when the soil is raised, the finish does not collapse, it is not brought to a certain distance to the ground. So that animals do not crawl into the gap, a metal mesh is fixed at the bottom.